Water treating vessels OVN

Description

Water treating vessels (OVN) are intended for the primary treatment of oilfield water from oil, mechanical impurities, gas and other elements in preliminary oil treatment of oil and water discharge plants.

In the process of oil production, a large amount of oilfield water is formed along the way, which, having treated, can be used further for technological purpose. For this, special equipment is installed at oil enterprises.

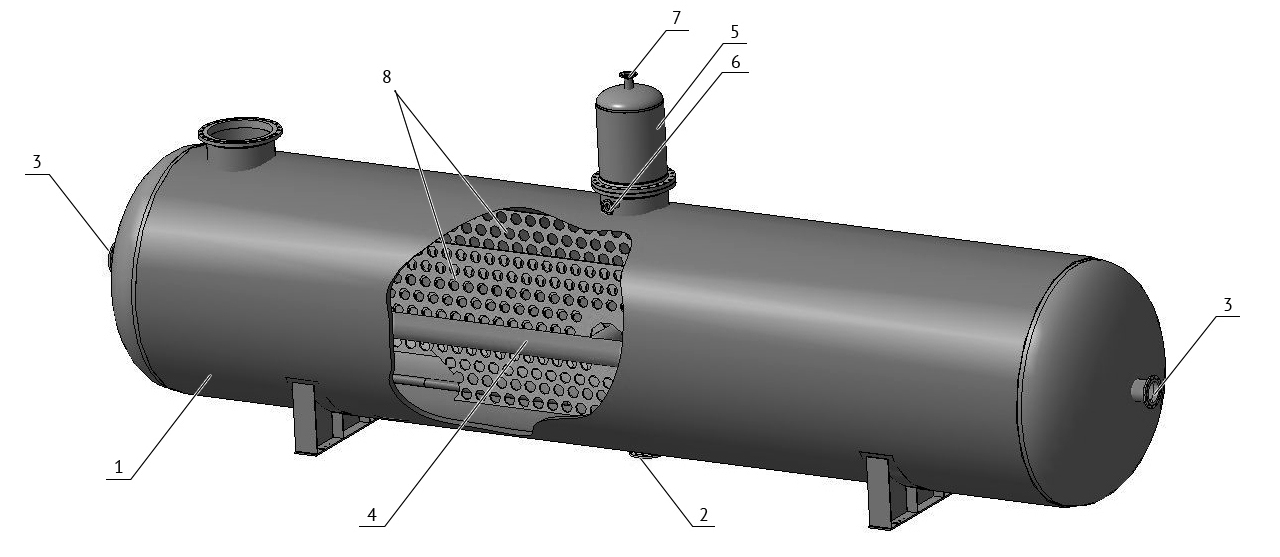

The design of the water treating vessels OVN

They appear as a horizontal cylindrical container, which is mounted aboveground on leg- or lug-supports. The design provides hatches and pipes through which serve for the inlet of the raw liquid and the outlet of treated water, capture and outlet of oil and gas.

Coalescing nozzles (filters) are inside the vessel, which merge drops of moisture, lately discharged. Renewal of nozzles is made when they are polluted, as it affects the production capacity and the degree of oil and impurities content in the discharged water. Renewal of filters is carried out through the manhole and ladder for service personnel.

Oil and gas are discharged through the neck, located in the upper part of the housing.

Operation can be fully automated by means of Instrumentation.

At the Customer's request, SARRZ manufactures the following structural designs of water treating vessels:

- on a metal frame

- in the heat-insulated block-box

- with ladder and service platform

- with heat insulation

At the operational location they are connected to the untreated water supply line and to the oil and gas extraction lines.

The distribution of the liquid flow inside is carried out uniformly, which excludes the formation of stagnant places.

At the Customer's request, additional equipment can be provided, i.e. a system of head sediments washing and equipment for the removal of diffused oil slime, which increases product capacity by maintaining a constant operating volume.

Water treating vessel scheme

1-housing, 2-oilfield water inlet, 3-treated water outlet with integral collection unit, 4-water distribution, 5-gas and entrapped oil gathering cap, 6-entrapped oil outlet, 7 - gas outlet, 8-coalescent filters package

Technical characteristics of the water treating vessel OVN

- volume-from 12 m3 to 200 m3

- product capacity-500-10000 m3/day

- pressure - 0.6-1.6 MPa

- the oil content in the inlet water - up to 500 mg/l

- the content of mechanical impurities at the inlet - up to 500 mg/l

- the oil content in the water at the outlet - 30-40 mg/l

- the amount of impurities in the outlet water - 20-30 mg/l

The manufacture of water treating vessels

Our Plant has the necessary Certificates of conformity for the manufacture of oil and gas tanks and separators.

To ensure a long service life (prevention of depressurization, sludging-up or occurrence of thinning areas), only steel grades resistant to corrosive nature of the working fluid are used for manufacture. Special attention is paid to anti-corrosion treatment of the inner surface.

After automatic or manual welding, weld inspection and leak and high-pressure tests are carried out.

Surface conditioning is carried out by means of sandblasting which guarantees equal anti-corrosive coating application.

Water treating vessels manufacture is carried out on the basis of individual requirements to pressure, product capacity, conditions of fluids at the inlet and outlet.

Summary tables of technical characteristics of oil, gas and water separators and sedimentation tanks can be found here.

How to order water treating vessels manufacture at the Saratov Reservoir Plant?

To buy a water treating vessel OVN, You can:

- call at +7(8452)250-288

- download the Questionnaire, fill it in and send it by e-mail

- e - mail technical requirements to equipment

- use the form "Request for quotation"

Our experts perform package of services:

- design

- water treating vessels manufacture

- delivery and installation

- equipment commissioning

We also carry out complex supply of the oil and gas production enterprise on individual terms of cooperation.

See also: