Hydrophobic water settling tanks

Description

Hydrophobic water settling tanks OGV-G are designed for produced water treatment from oil, gas and mechanical impurities at oil-productiong and refining enterprises. Having been treated produced water may be used for further technological purposes.

Design and operating peculiarities of hydrophobic water settling tanks

Structurally, this type of settling tanks is made in the form of a horizontal cylindrical vessel with elliptical heads. All around the shell there located fittings and pipes through which the feed stock enters, segregated substances (oil, gas, suspended particles) are discharged. Also, technological equipment that controls the process is installed into the fittings: pressure gauge, safety valve, thermometer, phase interface controller, and level gauges. The access to the inside of the vessel is made through a manhole, and accumulated impurities are removed through the stripping hatch.

The shell may be thermally insulated. It allows to operate the settling tanks at sub-zero temperatures without the use of process medium heaters.

The Saratov reservoir plant produces water settling tanks with a hydrophobic layer with a volume of from 25 up to 200 m3 of steel grades 16GS and 09G2S. We also perform design on the basis of the requirements and operating conditions presented by the Customer.Water settling tanks OGV-G are delivered to the site in full factory readiness: the tank is put into operation immediately after the tank is installed on the prepared foundation, and is connected to the feed and discharge pipelines and oil anf gas intake lines.

Water settling tanks OGV-G differ from other types of settling tanks by the internal baffles that form compartments, through the upper edges of which the produced water flows. In parallel, the liquid is cleaned from its components. The baffles are tightly welded to the lower part of the shell.

Baffles form compartments, the number of which depends on the required parameters of water treatment and the length of the tank. The compartments are connected to each other in pairs by a pipeline with a distributor.

Produced water treatment is carried by the hydrophobic layer in each compartment. Each layer is oil blanket and "detains" particles of oil, gas and other substances.

Produced water enters the tank above the level of the media interface through a feed pipeline, which has a distributor that is responsible for the uniform flow of liquid to the hydrophobic layer. When the liquid passes through the oil layer, oil particles are partially removed from the water. In the next compartment, the proccessed medium is filtered again and more thoroughly.

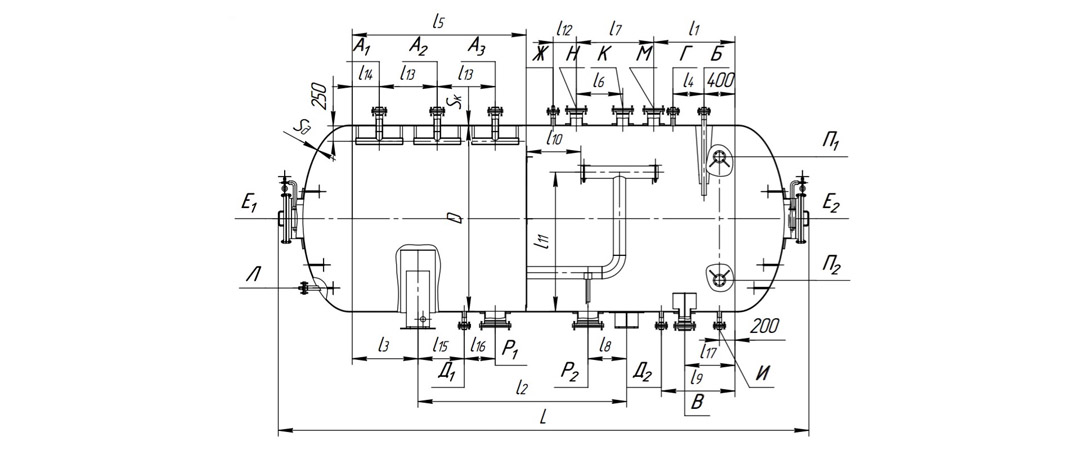

Hydrophobic water settling tank drawing

Nozzle schedule

| Designation | Assignment |

|---|---|

| А1, А2, А3 | initial product inlet |

| Б1 | oil outlet |

| В1 | water outlet |

| Г1 | gas outlet |

| Д1, Д2 | drainage |

| Е1, Е2 | manhole |

| Ж1 | pressure gauge |

| И1 | steaming |

| К1 | safety valve |

| Л1 | temperature probe |

| М1 | phase interface controller |

| Н1 | level control |

| П1, П2 | level gauge cabinet |

| Р1, Р2 | stripping hatch |

Overall dimensions

| Capacity, m3 | 25 | 50 | 100 | 200 |

|---|---|---|---|---|

| Liquid output, m3/day | 2000 | 4000 | 7500 | 15000 |

| Nominal pressure, MPa (kp/cm2) |

1,0 (10) 1,6 (16) 2,5 (25) |

1,0 (10) 1,6 (16) 2,5 (25) |

1,0 (10) 1,6 (16) 2,5 (25) |

1,0 (10) 1,6 (16) 2,5 (25) |

| Inside diameter | 2400 | 2400 | 3000 | 3400 |

| L |

6285 6290 6340 |

11485 11490 11540 |

14385 14395 11485 |

22090 |

| I | 4500 | 9700 | 12300 | 19800 |

| I1 | 600 | 1200 | 1500 | 2500 |

| I2 | 2700 | 6700 | 8000 | 13000 |

| I3 | 850 | 1500 | 2150 | 3400 |

| I4 | 350 | 500 | 700 | 1000 |

| I5 | 2250 | 4850 | 6150 | 9900 |

| I6 | 600 | 1200 | 1500 | 2500 |

| I7 | 1000 | 3000 | 3500 | 6000 |

| I8 | 500 | 1200 | 120 | 2000 |

| I9 | 500 | 800 | 1000 | 1000 |

| I10 | 700 | 1000 | 1000 | 1000 |

| I11 | 1800 | 1800 | 2200 | 2500 |

| I12 | 300 | 300 | 500 | 500 |

| I13 | 750 | 1600 | 2000 | 300 |

| I14 | 350 | 800 | 1000 | 1900 |

| I15 | 600 | 2000 | 2000 | 2000 |

| I16 | 400 | 800 | 1000 | 1000 |

| I17 | 300 | 400 | 500 | 500 |

Performance capability of the hydrophobiwater settling tanks

| Criteria | Value |

|---|---|

| Processing medium | produced water with oil, gas and mechanical impurities |

| Capacity, m3 | 25-200 |

| Processing capacity, m3/day | 2000-15000 (depends on the capacity) |

| Process pressure, MPa | 1.0; 1.6; 2.5 |

| Operating medium temperature, ºС | -60...+100 |

| Ambient temperature, ºС | -40...+60 |

| Climatic category | N, NF |

| Seismicity, points | до 8 (more than 8 at special order) |

How to order hydrophobic water settling tanks?

To purchase hydrophobic water settling tanks You may:

- call at +7(8452)250-288

- email at

We perform the full range of work:

- oil and gas facilities design

- separation equipment production

- delivery

- separation equipment installing

See also: