Laboratory

As part of the Saratov Reservoir Plant there is a laboratory that performs incoming material control and production quality control. The laboratory personnel has wealth of experience and expertise in Non-Destructive Testing for Quality Assurance and are regularly certified. Employees of the laboratory are certified at the second level.

Laboratory objectives

The Plant's laboratory carry out equipment and materials control in the following fields:

- Equipment for oil and gas industry

- tanks for oil and oil products

- Equipment for explosive and chemically hazardous production

- equipment of chemical, petrochemical and oil refineries, operating under pressure up to 16 MPa

- equipment of chemical, petrochemical and oil refineries, working under pressure over 16 MPa

- tanks for explosive and toxic substances storage

- centrifuges, separators

Quality control techniques

The metal structures and tanks control is carried out by the following methods:

- Visually-measuring method (VIC) by means of noninstrumental observation or technical optics application

- Ultrasonic technique by means of ultrasonic detector

- Dye-penetrant process to identify surface or penetration defects by using tracing fluid

The laboratory uses up-to-date equipment, which undergo regular verification, ensuring the quality and accuracy of measurements.

All the output products pass weld inspection to ensure safe and long-term operation of the equipment produced.

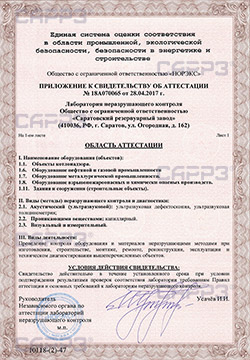

Certificate for NDT (non-destructive testing) control