Flare knockout drums

Description

Flare knockout drums (FS) are used in flare systems for associated petroleum gas treatment intended for combustion in flare units at gas-producing, gas-condensate and gas processing enterprises, from drip moisture, mechanical impurities and other suspended particles.

Flare knockout drum design

The housing of the flare knockout drum is a horizontal cylindrical vessel with elliptical heads. It is delivered to the facility in full factory readiness. Installation is carried out in the open space on the reinforced concrete foundation with the help of anchor bolts. To rigidly mount the drum there are supports at the lower shell.

Depending on the technical capability and operating requirements, they can also be installed in a heated room or delivered in block design (i.e. placed in a box-module of sandwich panels).

The design ensures compliance of noise level, vibration and gas contamination with Sanitary Regulations for Design of Industrial Facilities of the Russian Federation.

Inside there are angle and vertical filter strainers. The gas flows through the inlet nozzle under high pressure, passes through the angle strainer, which ensures uniform distribution of the working fluid inside, and conducts primary filtration of the associated gas.

The main cleaning and separation of the drip moisture takes place in a vertical filter strainer, where under the influence of gravitational forces, the moisture settles on the head and is discharged through a special connection to the drainage tank*. Treated associated petroleum gas rises and is fed via the outlet already to the flare unit.

Safety is ensured by the use of a safety valve and control and measuring instruments цршср monitor pressure, temperature and loading. The housing provides a manway, through which service personnel may get into the flare KO drum for routine maintenance.

*(not included in Flare knockout drum!)

At the Customer's request, the flare KO drum can be equipped with ladder and service platform, condensate pump, shut-off valves and valves and piping.

Saratov reservoir plant produces knockout drum of typical overall dimensions (1000, 1800, 2400, 3200 mm in diameter) and individual requirements specified in the Questionnaire.

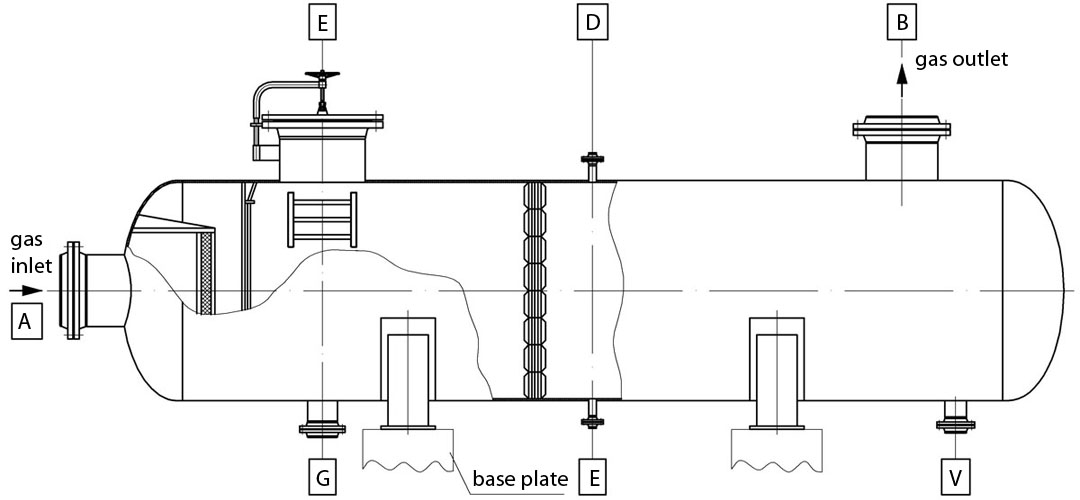

The scheme of KO drum

Nozzle schedule

| Designation | Assignment | Number, pcs. |

|---|---|---|

| А | gas inlet | 1 |

| B | gas outlet | 1 |

| V | liquid outlet | 1 |

| G | drainage | 1 |

| D | balance line | 1 |

| E | steaming | 2 |

Technical specifications

| № | Criteria | Value |

|---|---|---|

| 1 | operating product |

|

| 2 | volume, m3 | 4.0-200.0 |

| 3 | vessel type according to GOST 26 291-94 | 1 |

| 4 | hazard category of operating product according to GOST 12.1.007-76 | 4 |

| 5 | explosion group according to GOST R 51130.11-99 | IIA |

| 6 | atmospheric explosives group according to GOST R 51130.5-99 | Т3 |

| 7 | product capacity, nm3/day | up to 2200 |

| 8 | pressure, MPa | up to 4.0 |

| 9 | shell temperature, ºС | up to +150 |

| 10 | operating product temperature, ºС | from -50 to +50 |

| 11 | operating temperature, ºС | from -60 to +50 |

| 12 | purification efficiency, % | 99 |

| 13 | steel | 16GS, 16G2S, 09G2S |

| 14 | structural design |

|

| 15 | seismicity, points | up to 6 |

| 16 | projected service life, years | 12 |

Flare knockout drum manufacture

Low-alloy or carbon steel grades are used for the manufacture of flare knockout drum at the Saratov Reservoir Plant depending on the chemical composition of associated gas and operating conditions.

Due to the fact that associated gas negatively affects the shell, the inner surface can undergo thermal treatment at the factory. In this case, the negative impact is less and the service life of the equipment is extended.

Safe operation is ensured by high-quality automatic or semi-automatic two-side welding performed by our specialists, which guarantee the tightness of all welded joints. Hydraulic pressure testing and weld inspection by nondestructive inspection procedure and sonic inspection are carried out by Quality control department.

When installed in a cold climate to maintain a normal temperature, it is recommended to thermally insulate the flare knockout drum. For this both traditional methods (mineral wool mats and a steel protective cover) and high technologies, i.e. polyurethane foam insulation, are used. If necessary, an additional heat exchanger can be applied.

Advantages of flare knockout drums produced at the Saratov Reservoir Plant

- high production capacity due to the use of a proven layout of filter strainers (mesh pads)

- quality welds ensure integrity

- manufacture as according to standard drawings, and by the individual order

- full compliance of the output products with the state industrial safety standards

- simple delivery and mounting

How to order a flare knockout drum at the Plant?

The flare knockout drum design is carried out on the basis of operating conditions and Customer requirements. For your convenience, You can:

- call at +7(8452)250-288

- download the Questionnaire and e-mail it at

- use the forms "Request for quotation" или "Equipment request"

As a manufacturer of flare KO drums, the Plant also provides other services for the construction of oil and gas facilities:

- design of flare systems, as well as design development of oil and gas facilities

- manufacture of equipment for flare systems

- delivery at place

- assembling of flare systems

See also: