Centrifugal separators

Description

Centrifugal (cyclone) vertical separators (SCV) are gas-liquid separators and are used at oil and gas production and processing facilities for separation of gas and gas-oil flow. Their main functions are:

- separation of associated petroleum gas from produced oil (oil degassing)

- fine cleaning of associated petroleum gas from dripping liquid and water mist, gas condensate, contamination and various suspended particles and liquids

- gas cleaning before feeding to the flare unit

- associated gas treatment before its further use for transport or as fuel

The set-up and principle of action of centrifugal separators SCV

Centrifugal separators SCV are a vertical cylindrical vessel with elliptical heads. There is a treated gas outlet nozzle on the lid.

At the Plant the head is welded to the supports which at the worksite are installed on the reinforced concrete base and fixed by anchor bolts.

Depending on the operating conditions of vertical centrifugal separators SCV can be operated both outdoors and in a heated room. Upon special request cyclone separators can be supplied in block-modular design. It also can be thermally insulated or equipped with explosion-proof electric heating system.

Suspended solids, water mist and etc. Removal is carried out manually by means of a drain valve or automatically through the drain pipe when the solenoid valve is activated (optional).

Condensate drums (a separate condensate collector) is not included in the scope of delivery of the separator. It is made separately at the Customer's request. Gathering of the separated liquid is carried out in the lower part.

For the safe operation separators SCV can be equipped with a level gauge of accumulated liquid , liquid-level indicator, differential pressure gauge, differential pressure gauge, safety valve, sampler equipment and etc. according to Customer's requirement.

In order to calculate the cost of the separator and select main equipment, send a filled in Questionnaire to e-mail , and our specialist will contact you to clarify the order.

The principle of action of vertical centrifugal separators

Maximum liquid-gas mixture treatment is achieved as the result of three separation stages, each of which is based on different physical laws of cleaning of different media - inertial, gravitational and centrifugal. First, the working medium is cleaned in the deflector, then - in a separation multicyclone package, and the last stage - separation of moisture and particles in the demister blanket.

The inlet pipe is perpendicular to the radius of the separator. The gas-liquid flow enters the deflector with a variable cross-section, which creates a downward movement along the shell. Inertial forces deposit water mist and solid particles on the inner surface of the deflector, where they fall into a accumulation tank. Under the influence of centrifugal forces, droplets and particles settle on the surface and fall into the collection compartment. Then the already partially purified gas-liquid flow passes at an angle through the plates of the separation package, on which the suspended particles and the drip liquid are also deposited. When the flow from the head up changes, the gas flow is sucked into the separation multicyclone package. At this stage, the so-called "tornado" is formed: the gas is drained and cleaned due to a change in pressure and temperature. Between the accumulation tank and the package is a device that prevents accumulated fluid removal.

Specially designed and implemented a separation package promotes water mist coagulation and solid particles removal with constant saving centrifugal movement of the working medium.

To increase the efficiency of the separator speed controller of gas-liquid mixture rotation can be installed.

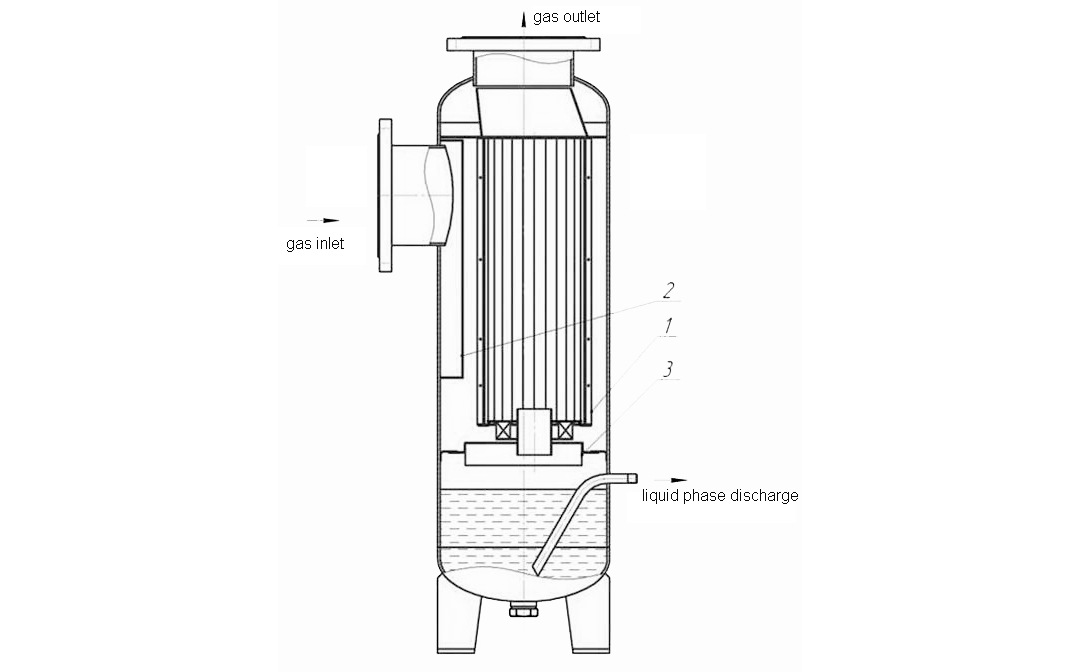

Scheme of the centrifugal separator SCV

1-separation package, 2-air deflector, 3-lower flow breaker

Characteristics of the centrifugal separators

| № | Criteria | Value |

|---|---|---|

| 1 | oparating product | associated petroleum gas, natural gas, inert gas, petroleum product, compressed air, gas condensate |

| 2 | operating pressure, MPa | up to 35.0 |

| 3 | gas output, nm3/day | up to 100 millions |

| 4 | liquid output, nm3/min. | unlimited |

| 5 | liquid content in output, g/m3, not more | 0.004 |

| 6 | suspended particles contentin output, g/m3, not more | 0,003 |

| 7 | purification efficiency, % | 97-99,98 |

| 8 | pressure loss, MPa | 0.003-0.03 |

| 9 | operating temperature, ºС | -60 до +60 |

| 10 | media temperature, ºС | from -30 to +100 |

| 11 | seismicity, points | up to 9 |

| 12 | the material |

|

| 13 | service life, years | 10-30 |

Advantages of centrifugal separators produced at the Saratov reservoir plant

- high productivity thanks to their production only after incoming material control

- maintainance of gas-liquid mixture cleaning efficiency even in case of inlet pressure variation

- pressure loss reduction

- the absence of rubbing and rotating structural elements prolongs the service life of the equipment

- increased productivity and efficiency while maintaining overall dimensions

How to buy vertical centrifugal separator SCV at the Plant?

In order to find out the cost of the centrifugal vertical separator, our experts carry out technical calculations based on the operating conditions and Customer requirements. For your convenience, You can:

- call at +7(8452)250-288

- download the Questionnaire and send an e-mail

- use "Request for quotation" или "Equipment request" forms

Being a manufacturer of centrifugal separators, the Saratov Reservoir Plant also carries out other services in construction of oil and gas facilities:

- facility design of oil and gas industry

- production of separation equipment for oil and gas facilities

- delivery of equipment at site

- installation of oil and gas separation units

See also: