Flotators-degasifiers FD

Description

The flotator-degasifiers are used in the oil and gas producers for produced water treatment. Their main purpose is separation and gathering of gas and oil from crude produced water at oil primary treatment and initial water separation facilities.

The functions of the flotators

- produced water treatment from contamination

- oil and gas separation and gathering from produced water

- treated produced water discharge

- purification of captured gas from dripping liquid

Design of flotator-degasifiers

They have the form of a horizontal cylindrical vessel with elliptical heads. Installation is carried out only aboveground on support-legs or support-lugs, which are mounted on a prepared аoundation.

At the Customer's request the Saratov Reservoir Plant additionally performs other design. For example, flotators of small volume can be supplied on the metal frame, which greatly simplifies their installation and allows to transport the equipment as needed to new facilities. It is also possible to manufacture flotator-degasifiers in block-modular design: the vessel itself, piping and auxiliary technological devices (for example, pumps) are installed in a block-modular container made of sandwich panels. This design allows to protect flotator from environmental factors (temperature, precipitation, etc.) and against unauthorized access.

If it is necessary to install flotator of a large volume, we may supply stairs, service platforms and other walling.

At low operating temperatures, the insulation of flotators-degasifiers is performed.

Mode of action of flotators-degasifiers FD

The interior structure allows to achieve the best produced water treatment due to use of the phase destabilizer DFS. This destabilizer releases produced water from particles of emulsified oil and gas by pressure decline in the flotation zone.

Untreated produced water enters the flotation vessel through the inlet pipe and passes through the destabilizer. Inside, the pressure declines, so the dissolved gas is released from the water. In addition, condensed moisture is removed from the gas. Gas pockets meet with emulsified oil, are gathered in the tray and the oil collectors, and then are discharged through the head nozzle.

If there is not enough gas in the produced water, a return feed pipe of the captured and collected gas is provided.

At the outlet it is purified produced water, ready for further use.

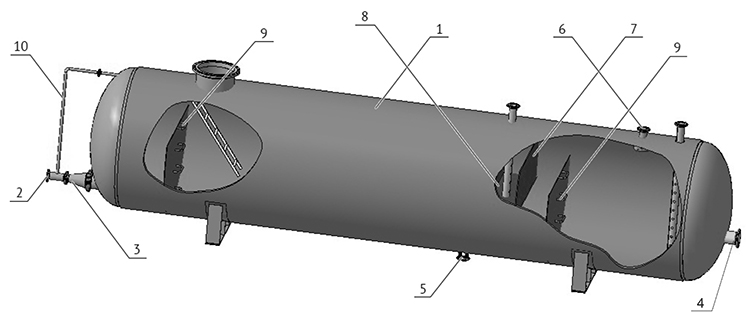

Flotator-degasifier scheme

1-housing, 2-water inlet, 3-fluid phase destabilizer, 4-water outlet, 5-oil outlet, 6-gas outlet with stationary liquid entrapping device, 7-oil collector, 8-tray for trapped oil, 9-weir gate, 10-gas feedline

The volume, overall dimensions and the configuration are custom designed depending on the technical specifications of the liquid at the inlet, the necessary physico-chemical composition of the treated water, the required performance and operating conditions.

The production of flotator-degassers FD

The Saratov Reservoir Plant has the necessary Certificates of conformity for the manufacture of oil and gas vessels and separators.

The Plant SARRS produces flotators-degasifiers FD of high-resistance steel grades that can withstand the negative effects of aggressive environment and exploitation rate.

The manufacturing process consists of several stages: first, sheet metal is cut into blanks for the main and auxiliary metal structures (heads, shellss, pipes, hatches, stairs, supports, etc.). Then manual or automatic welding of all elements is carried out, after which weld inspection, leak and high pressure tests are carried out.

To protect against the negative impact of the operating product, the inner surface is first sandblasted, and then covered with anticorrosive compositions.

Technical characteristics and parameters of flotators-degasifiers of our own make are reflected in final completion protocols and the Product certificates which are delivered in a set.

Specifications of flotators

- performance - 1.000-10.000 m3/day

- volume - from 25 m3 to 200 m3

- pressure - from 0.6 to 1.6 MPa

- the gas content at the inlet - up to 100 l/m3

- oil content at the inlet - up to 100 mg / l, at the outlet - up to 20 mg / l

- the amount of mechanical impurities at the inlet - up to 50 mg / l, at the output - up to 15 mg / l

The advantages of flotation-degassers FD produced by our Plant

The following advantages can be listed:

- high degree of treatment

- reliability-and-quality assurance of flotators throughout the service life due to the use of state-of-the-art technology while designing and manufacturing, as well as an individual approach

- easy access to the interior for maintenance

- the possibility of flotation-degassers manufacturing for a specific site

- compliance of the manufactured goods with the state norms and standards, availability of Safe for operation Certificate

Summary tables of technical characteristics of oil, gas and water separators and sedimentation tanks can be found here.

How to order the flotator-degasifiers FD??

In order to enquire the cost of the flotators, You can:

- call at +7(8452)250-288

- send an e-mail at with technical requirements or the filled-in Questionnaire

- use the "Request for quotation" form, fill in the contact information, and our specialist will call you back to hammer out details

In addition, we perform the following:

- flotators-degasifiers FD mounting

- commissioning of separation equipment

- complex manufacture of the equipment for Your enterprise on individual cooperation terms

See also: