Horizontal settling tanks OG

Description

Petroleum settling tank OG are designed to remove formation water, mechanical impurities and salt from oil. They areused at oil production and processing enterprises and preliminary water and oil processing terminals.

Petroleum settling tank OG design

This type of settling tank has horizontal shape with elliptical bottoms. Insude there are placed devices that allow you to retain mechanical particles and condensed moisture. The latter is then removed and used for technological purposes.

SARRZ produces horizontal settling tanks with a volume of from 25 up to 200 m3. The tanks are delivered to the operational location in maximum factory readiness as the body is all-welded with tank hatches and fitting pipes at the top and supports at the bottom.

SARRZ produces horizontal settling tanks with a volume of from 25 up to 200 m3. The tanks are delivered to the operational location in maximum factory readiness as the body is all-welded with tank hatches and fitting pipes at the top and supports at the bottom.

The settling tanks are mounted aboveground: the are supports at the lower shell to settle the tank onto the reinforced concrete foundation.

Stairs and service platforms may be provided for personnel access to the fittings.

Structural design of the settling tanks OG are carried out on the basis of the Data sheet or technical requirements for production. The volume depends on the desired capacity. The steel grade depends on the crude-oil emulsion composition. We produce settling tanks of 16GS os 09G2S with a thickness of up to 16 mm. Inner surface is treated with special anticorrosion primers. Optionally the tanks may be heat-treated. The outer surface is also covered with primer and enamel. If needed, the heat insulating may be applied on the outer side that will prevent crude-oil emulsion from freeze and thickening.

Settling tanks specifications

| Criteria | Value |

|---|---|

| Volume, m3 | 25-200 |

| Capacity, m3/day | 2000-15000 |

| Operating medium | crude-oil emulsion |

| Oparating pressure, MPa | 1.0; 1.6; 2.5 |

| Operating medium temperature, ºС | -60...+100 |

| Climatic category | N, NF |

| Operating temperature, ºС | -40...+60 depanding on the material design |

| Material | 09G2S, 16GS |

| Seismicity, points | up to 9 |

| Service life, years | not less than 20 |

Internal arrangement of the settling tanks OG

There is formation water inside the sump. The oil-water emulsion enters through the inlet pipe. The holed plates and box-shaped distributers are located in the lower part. While passing through them, the emulsion is separated into water and oil due to their density margin. As the oil density is less, it goes up to the upper part. The treated oil goes to the oil gathering line and is discharged. Separated water joins with formation water and is gravitated to the bottom and then discharged to the formation water treatment unit.

The emulsion also contains gas particles which are gathered in the special collector and then are also discharged.

Each settling tank OG is equipped with a set of measuring and shut-off devices: an interfacial level gauge, a regulator valve, a sampler, a pressure gauge, and a safety valve. The exact composition of the equipment is selected at the design stage.

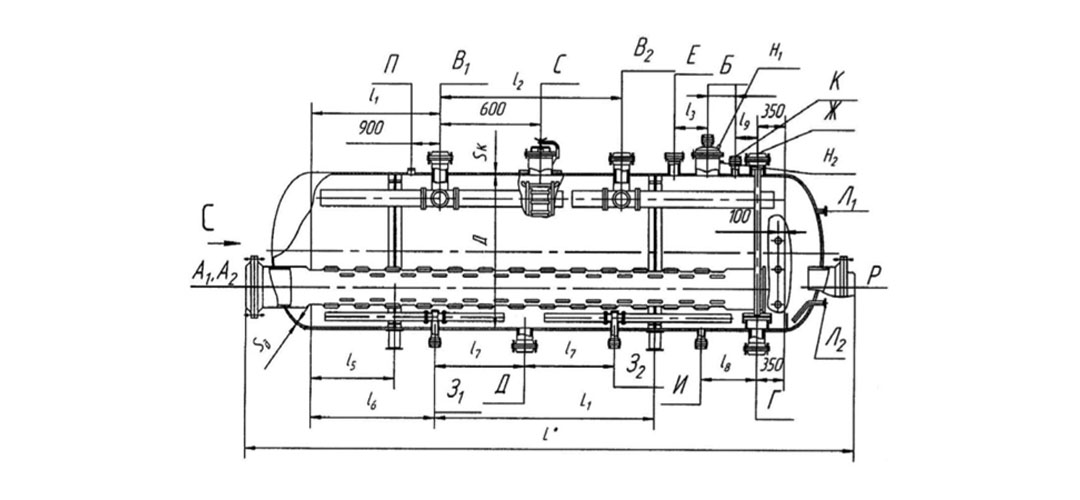

Typical drawing of the settling tank OG

Typical overall dimensions

| Volume, m3 | Inside diameter | L | B | H | Sk | S д | l1 | l2 | l3 | l4 | l5 | l6 | l7 | l8 | l9 | l10 | h1 | h2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 2400 | 12900 | 2520 | 3215 | 10 | 12 | 5500 | - | 1150 | 1550 | 2500 | 5500 | - | 800 | 500 | 930 | 490 | 300 |

| 100 | 3000 | 14000 | 3040 | 3920 | 14 | 16 | 2940 | 5780 | 680 | 900 | 1830 | 3065 | 265 | 680 | 400 | 1050 | 500 | 400 |

| 200 | 3400 | 22000 | 3432 | 4320 | 16 | 20 | 4925 | 9650 | 875 | 1100 | 4000 | 4700 | 4750 | 1000 | 500 | 1450 | 700 | 600 |

Nozzle schedule

| Designation | Assignment, DN, mm | OG-50P | OG-100P | OG-200P | |||

|---|---|---|---|---|---|---|---|

| DN, mm | pcs | DN, mm | pcs | DN, mm | pcs | ||

| Ф1, А2 | crude-oil emulsion inlet | 350 | 2 | 500 | 2 | 700 | 2 |

| Б | gas outlet | 300 | 1 | 80/500 | 1 | 80/500 | 1 |

| В1, В2 | oil outlet | 200 | 1 | 300 | 2 | 300 | 2 |

| Г | formation water outlet | 200 | 1 | 300 | 1 | 300 | 1 |

| Д | drainage | 200 | 1 | 300 | 1 | 300 | 1 |

| Е | safety valve | 200 | 1 | 200 | 1 | 200 | 1 |

| Ж | level control | 300 | 1 | 300 | 1 | 300 | 1 |

| З1, З2 | cleaning | 200 | 1 | 150 | 2 | 150 | 2 |

| К | level control | 200 | 1 | 10 | 1 | 10 | 1 |

| Л1, Л2 | level control | 50 | 2 | 50 | 2 | 50 | 2 |

| М1, М2, М3 | sampling connection | 15 | 5 | 15 | 3 | 15 | 3 |

| Н1, Н2 | differential pressure gauge | 15 | 2 | 15 | 1 | 15 | 1 |

| П | pressure gauge connection | 15 | 1 | 15 | 1 | 15 | 1 |

| Р | hatch | 500 | 1 | 600 | 1 | 800 | 1 |

| С | manhole | 500 | 1 | 500 | 1 | 500 | 1 |

| И | drainage | 150 | 1 | 150 | 1 | 150 | 1 |

How to buy settling tank at SARRZ?

In order to know the price, you may:

- call at 8-800-555-9480

- email zakaz@sarrz.com

- fill in the Data sheet and send it at e-mail zakaz@sarrz.com

We perform a full range of services: design development, volume calculation depending on the required performance, the selection of the steel grade and method of anticorrosive treatment, oilfield equipment manufacturing, shipping separation units, installation of settling tanks and vessels and their commissioning.

See also: