Three-phase separators TFS-L

Description

Three-phase separators TFS (TFS-L) are used as a part of the preliminary water discharge unit and oil treatment plants at oil-field facilities.

Oil emulsion is produced with a large quantity of gases, impurities and oilfield water. Before crude oil can be used for commercial purposes, the initial oil product should be dewatered and degassed, that is, it should be free of water and gas molecules, respectively, as they reduce the efficiency of processing of oil and negatively affect the transport pipelines. Therefore, to obtain high-quality products at the output crude oil must be treated.

Functions of three-phase separators TFS-L

- separation of extracted oil products into three fractions: oil, gas condensate and water

- oil gas purification from suspended particles, oil, condensate and moisture

- discharge and produced water treatment

- dehydration of oil up to 5-20%

Three-phase separators TFS-L configuration

Structurally, they are a cylindrical horizontal vessel on supports with elliptical heads. Their mounting is carried out only aboveground. In the housing there are fittings for the working fluid inlet, the outlet of dehydrated oil, processed gas condensate and oilfield water. In addition, the fittings are equipped with technological equipment - level gauges, pressure gauges, level and temperature sensors, safety valves, instrumentation with the ability to transmit data to the control panel. Instrumentation And automation system contributes to the uninterrupted operation, as automation can be adjusted to automatically producing capacity alteration if the input fraction parameters changing occurs, as well as to the termination of the process or product discharge in the event of a change in pressure or other force majeure.

Plant SARRS also manufactures separators TFS-L with thermal insulation or a heater to maintain the temperature.

Inside the separator TFS-L is divided into several sections by partitions. In the first section, the oil emulsion dehydration and coalescence of the released liquid in the capillary occurs. Next section contains the oil collector for refined oil.

At the Customer's request TFS-L can be completed with a slot gas separator that releases condensate from the separated gas.

Three-phase separators TFS-L can be made in a modular design: the separator and piping are mounted on a metal frame. This modular design is convenient for transportation, installation and makes the equipment mobile. The separator specially manufactured can be installed in thermal insulated block-box.

The design of the TFS-L separator, design characteristics, overall dimensions depend on the individual demands of the Customer. For large volume separators we recommend to equip the ladder and service platform to provide access for maintenance personnel.

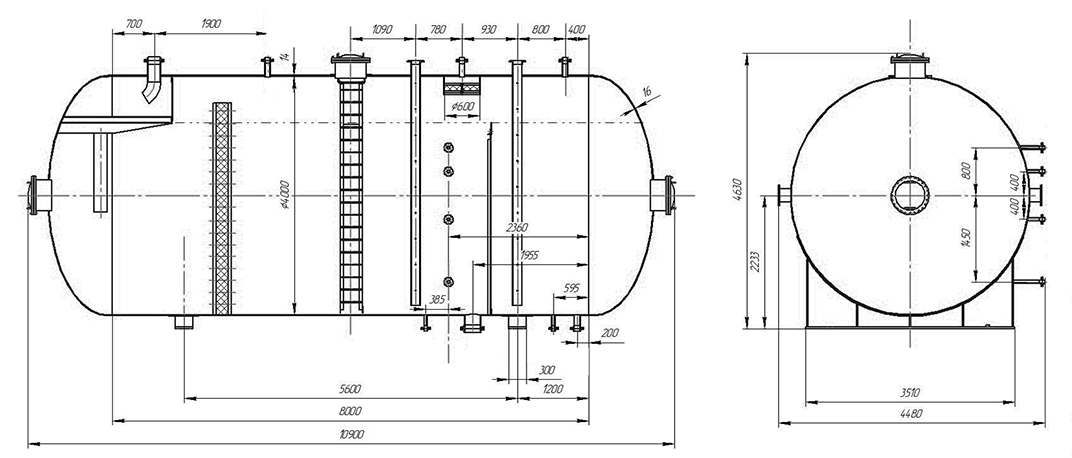

General scheme of three-phase separator TFS-L

Technical characteristics of three-phase separators TFS-L

- volume - 12-200 m3

- pressure - 0.6-3.0 MPa

- liquid capacity - 1000-12000 m3/day.

- gas factor - up to 200 Nm3/t

- water content at the inlet - up to 50%

- water content at the outlet - up to 10%

- the maximum temperature of the working product - 100ºC

- retention period of the oil emulsion in the separator - up to 30 min.

Manufacture of three-phase separators TFS-L

The Saratov Reservoir Plant has the necessary Certificates of conformity for the manufacture of oil and gas tanks and separators.

Three-phase separators of TFS series are customized on the basis of the provided requirements for the final product and data on the initial fraction.

The design and choice of steel grade are influenced by the following factors: operating pressure, required producing capacity and chemical composition of the oil fraction.

In order to ensure safe operation of TFS-L separators during the entire service life (20 years), the steel must be resistant to the negative impact of aggressive fluid. Therefore, low-alloy structural steels are used.

The manufacturing process begins in the preshaping for the shell, heads, fittings, nozzles, manholes and supports. Then welding is performed by automatic welding key. The necessary step is welding quality control, leak testing and high-pressure test.

Special attention is paid to anticorrosion treatment of the external and internal surfaces. First the surfaces are sand-blasted. Next, all structural elements are applied to special compositions (coating, enamel).

All performed works are accompanied by final completion protocols, and at delivery the Product certificate is issued.

Summary tables of technical characteristics of oil and gas separators and sedimentation tanks can be found here.

How to buy TFS-L three-phase separator at the Sarrz Plant?

For three-phase separator TFS-L design and manufacture order, You can:

- call at +7(8452)250-288

- e-mail at о Вашей потребности

- download the Questionnaire, fill it in and e-mail it

- use the form "Request for quotation"

The Plant also provides other services of oil and gas facilities construction:

- engineering surveys at the facilities

- design of oil and gas facilities

- manufacture of separation equipment

- delivery of separators and sedimentation tanks to the field

- separation equipment mounting

See also: