Oil-settling tanks ON

Description

Oil-settling tanks ON serve to oil dehydration and gas emission at the oil desalting and dehydration plant.

The Saratov Reservoir Plant produces settling tanks ON with a volume of up to 200 m3 in horizontal design. Upon special request it is also possible to supply vertical tanks.

Settling tanks ON design

Settling tanks are manufactured in a horizontal design with a vertical feed of oil emulsion.

The tank is delivered to the facility in full factory readiness, which allows to immediately install it on a reinforced concrete foundation and put it into operation.

The settling tanks are operated with highly corrosive liquids. To protect the inner surface of the shell, it is covered with anti-corrosion compounds. At the customer's request, heat treatment of the housing is possible. Also the internal devices are made of stainless steel for long life of the oil settling tanks.

If the settling tanks are planned to be operated in a cold climate, the housing may be heat-insulated.

Operating peculiarities

To function there are manholes, fittings and pipes all around the tank. They serve to oil emulsion inlet, dehydrated oil outlet, gas disposal, drainage and steaming, sludge removal, and processing equipment installation, i.e. pressure relief valve, gauge, interfacial level gauge, level control, pressure gauge.

The watered oil is fed to the tank through the inlet connection and distribution device. Inside there are metal baffle plates made of grating. Due to the settling and mixing processes, water and gas are separated. The separated water discharge is performed automatically after having got interfacial level gauge signal.

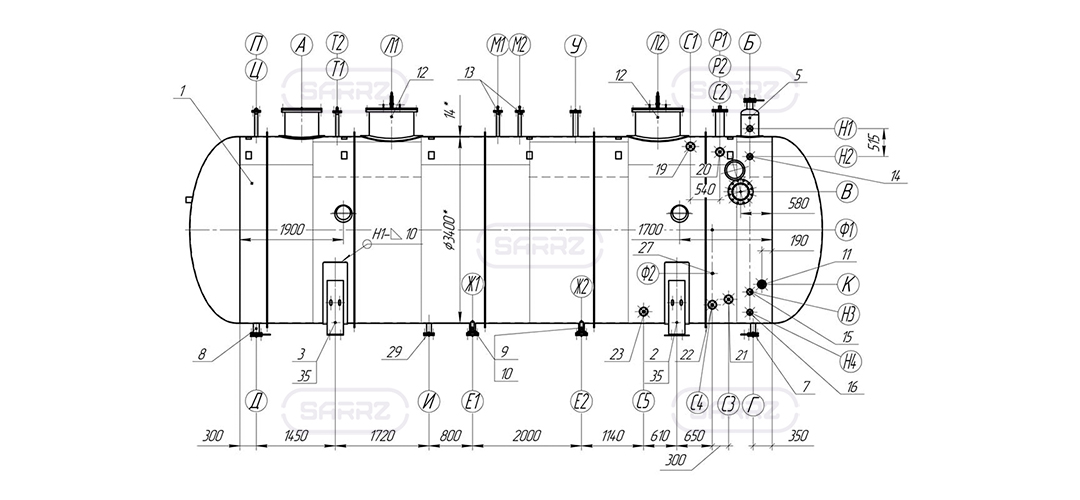

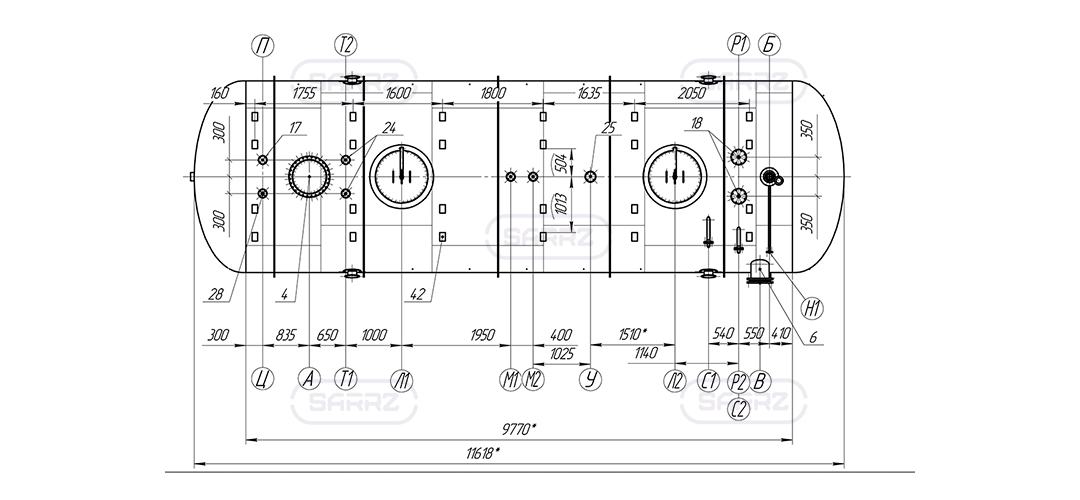

Settling tank ON 100 m3 drawing

Nozzle schedule

| Designation | Application | Designation | Application |

|---|---|---|---|

| А | crude-oil emulsion inlet | М2 | pressure sensor |

| Б | gas outlet | Н1...Н4 | visual level gauge |

| В | oil outlet | П | steaming |

| Г | water outlet | Р1, Р2 | level transmitter |

| Д | drainage | С1...С5 | level alarm |

| Е1, Е2 | sludge removal | Т1 | temperature probe |

| Ж1, Ж2 | water inlet for sludge washout | Т2 | temperature sensor |

| И | water inlet into the collector for sludge washout | У | safety valve |

| К | intermediate phase sampling | Ф1 | sampler opener |

| Л1, Л2 | manhole | Ф2 | sampler opener |

| М1 | pressure gauge | Ц | gas inlet |

Specifications

| Criteria | Value |

|---|---|

| Operating madium | crude-oil emulsion |

| Volume, m3 | 12.5-200 |

| Capacity, m3/day | up to 14000 |

| Operating pressure, MPa | 1.0; 1.6; 2.5 |

| Medium temperature, ºС | +30...+90 |

| Residual water content in oil, % mass. | 0.5...2.0 |

| Oil and mechanical impurities content in formed water in output, mg/l | up to 40 |

| Operating temperature, ºС | -60...+50 |

| Climatic category | NF |

| Seismicity, points, max | 8 (more than 8 at special order) |

| Material | 09G2S, 12Х18Н10Т, St3 |

| Service life, years | 20 |

How to buy settling tank ON?

In order to get the price quotation you may:

- call at +7(8452)250-288

- email at

The advantages of cooperation with our Plant are:

- high quality of the supplied equipment, which guarantees reliable and safe operation

- individual approach when equipment design

- favorable terms of cooperation

- individual delivery conditions when applying for a set of separation and storage equipment

See also: