Silos for liquids

Description

Metal silos for liquids are designed for chemical, petrochemical, pharmaceutical industries for long-term and short-term storage of soft and hard water, solutions, as well as different chemically non-aggressive medium. Their storage is possible at any time of the year in regions with a warm, moderately cold and cold climate.

The Saratov Reservoir Plant produces silos of different volume, with a minimum capacity of 5 m3.

They are mounted aboveground, which requires the clearing of the site and the preparation of a waterproofing foundation. Waterproofing allows to prevent the destruction of the concrete base by moisture and atmosphere precipitation.

Design of silos for liquids

They appear as a closed sealed vessel for liquid products, vertically oriented. Silos for liquids are manufactured of structural steel grades 09G2S or St3sp5 with corrosion-resistant coating.

The roof, as well as the bottom, can be of two types: conical and flat.

The conical bottom is optimally suited for short-term liquid storage during technological operations, for example, their cleaning. Their installation is made on special metal supports, the height of which is determined by the requirements of the project.

Flat bottom is used when long-term storage of substances or operating with a large volume is required.

Complete set of steel silo for liquids

The finished silo is shipped to the facility together with the necessary set of metal structures, which includes:

- stairs with circular cage;

- service platforms with grille flooring;

- supports welded to the body or supplied separately.

At the Customer's request, the silos may be produced with an additional nozzle for the displacer level instrument installation, which determines filling level.

Specifications* of silos for liquids

| Criteria | Value |

|---|---|

| Volume | 5 m3 and more |

| Designed shell temperature | +115°С |

| Minimal shell temperature | -40°С |

| Density of stored product | up to 900 kg/m3 |

| Corrosion velocity | 0.1 mm per year |

| Corrosion allowance | 1 mm |

| Material | St3sp5, 09G2S |

| Projected service life | up to 10 years |

| Number of stress cycles throughout service life | up to 1000 |

Weight and dimensions are designed according to the required volume, as well as the requirements to materials and installed equipment.

In addition, it is possible to increase the resistance of steel to the negative impact of the environment by anti-corrosive coating application, which ensures a long service life of the silo.

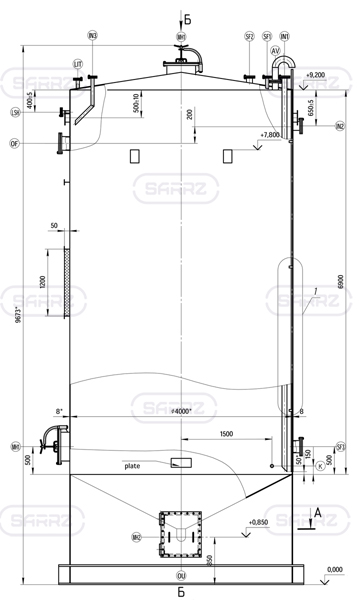

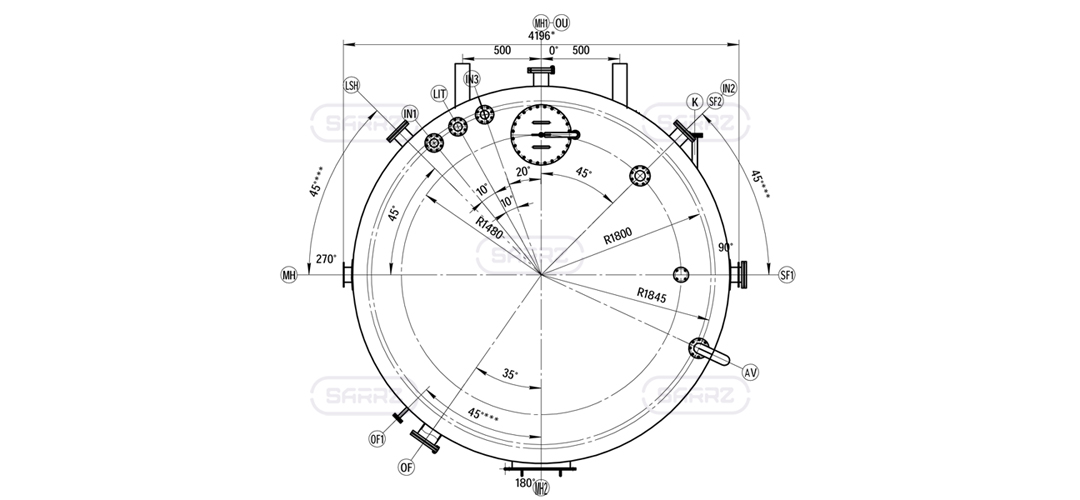

Drawing of the silo fittings location

| Designation | Assignment | Nominal inside diameter DN, mm | Pressure PN, MPa |

|---|---|---|---|

| IN1 | Inlet | 80 | 1.6 |

| IN2 | Inlet | 150 | 1.6 |

| IN3 | Inlet | 50 | 1.6 |

| MH1 | Manhole | 500 | 1.6 |

| AV | Venting | 100 | 1.6 |

| SF1 | Reserve | 100 | 1.6 |

| SF2 | Reserve | 50 | 1.6 |

| OF | Overflow | 100 | 1.6 |

| OU | Outlet | 80 | 1.6 |

| LIT | Level | 50 | 1.6 |

| LSH | Level | 50 | 1.6 |

| SF3 | Reserve | 300 | 1.0 |

| K | Reserve | 50 | 1.6 |

| OF1 | Reserve | 50 | 1.6 |

*These characteristics are for reference and may differ from the values given in the project.

The advantages of silos for liquids, manufactured by the Plant SARRZ

- Design and manufacture of silos for liquids is carried out in sin compliance with the technical specifications.

- Manufacturing process is built to meet the requirements of industry standards and norms.

- Possibility of delivery of finished silos to any region of Russia.

- No extra charges for intermediaries: the price is set by the manufacturer.

How to buy silo for liquid product?

Silos for synthetic / vegetable oils and water storage can be ordered from the representatives of the Plant SARRZ in one of the following ways:

- call at +7(8452)250-288 for all regions

- call at +7(8452)250-288 for Saratov and Saratov region

- send operating requirements or Technical specification at e-mail

- use the form "Request for quotation", provide contact information, and our specialist will contact you

See also:

| Rectangular tanks | Silos for granular materials | Silos for liquids |

| Silos for bulk materials | Surge tanks | Non-pressure tanks |

| Pressure tanks | Hot wells | Tanks for CHP-plants, NPGS and HPP |

| Stainless steel tanks |