Silos for granular materials

Description

Plant SARRZ offers services of the design and manufacture of steel silos for granular materials with a volume of 5 m3 and more. Silos provide high-quality long-term and short-term storage of wet spent grains, meal, bran, animal feed additives and mixtures, as well as other products of oil extraction production.

Vessels for granulated bulk materials can be operated at production facilities in any region of Russia with a warm, mild-cold and cold climate. They are mounted aboveground on a pre-arranged foundation with water proofing. Waterproofing of the foundation allows to prevent its destruction under atmospheric influences.

Silos for granular materials design

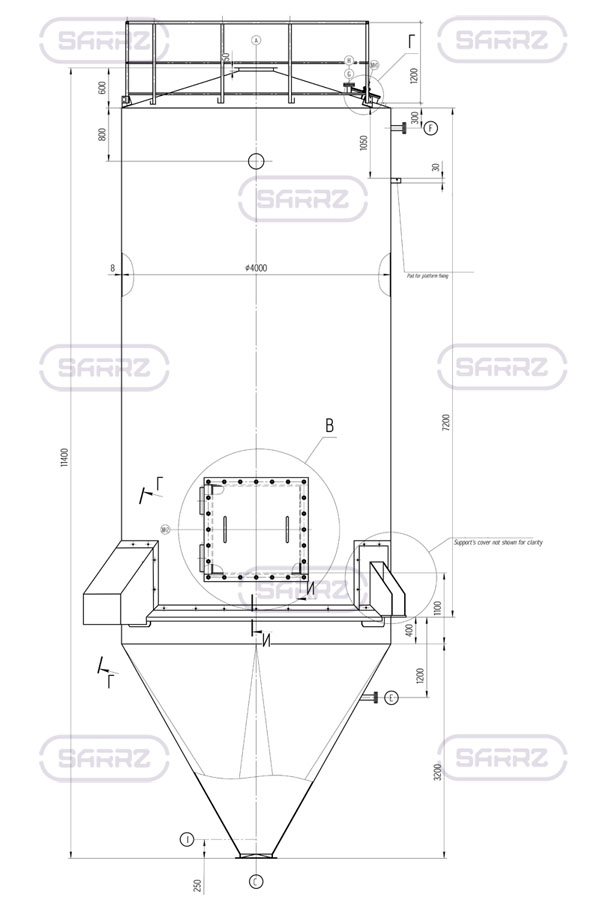

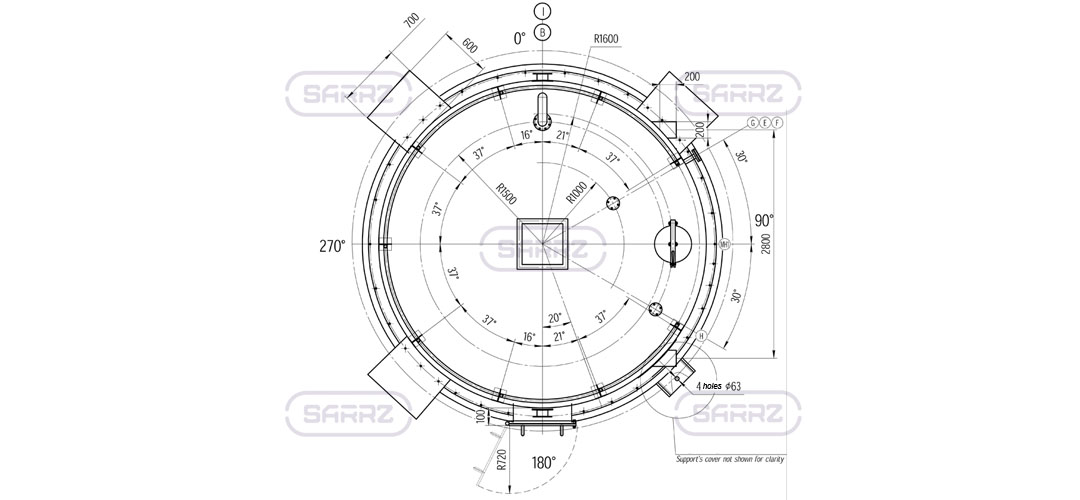

Silos for spent grains, feed mixtures and other granular products appear as closed cylindrical vessels with vertical orientation. During manufacturing structural steel grades St3sp5 or 09G2S are used.

The minimum shell temperature should not be lower than -40°C. When operating with wet product, low temperatures can lead to freezing of the product in a silos. At the Customer's request to prevent freezing it is possible to make a silo with heating and thermal insulation.

The roof can be flat or conical, depending on the technological requirements at the facility. The choice of the bottom type is also selected depending on the specific conditions: flat bottom is used for a large volume of granular material, cone - for short-term storage or for shipment to auto or railway transport.

Equipment and service of silo for granular materials

Finished silo is supplied with a set of metal constructions: stairs with circular cage, supports for installation and maintenance. If it is necessary to unite the vessels into a single technological group, the the transport bridge is provided.

Additional equipment may include:

- dosing augers (screw conveyors) for the required volume of product discharge;

- screw closures, designed to stop the flow of product from the silo to the receiving funnel;

- flaged level gauges for determining the filling of a silo with a granular material.

In case of long-term operation, contamination may occur inside the casing, which should be periodically removed from the inside. Timely cleansing of the silo allows to avoid microbiological spoilage of the product, to prevent the appearance of harmful insects, to reduce the number of antiseptic treatments and disinfection. Cleaning is carried out from top to bottom, which allows to clear up mixture deposits and partial ratholing with dry mechanical or hydraulic methods.

Specifications* of granular material silos

| Criteris | Value |

|---|---|

| Minimal capacity | 5 м3 and more |

| Designed shell temperature | +40°С |

| Minimal shell temperature | -40°С |

| Stored product density | up to 550 kg/m3 |

| Сorrosion velocity | 0,1 mm per year |

| Corrosion/errosion allowance | 1 mm |

| Silo and supports material | St3sp5, 09G2S |

| Projected service life | up to 10 years |

| number of stress cycles over service life | up to 1000 |

*Dimensions and weight are designed by the specialists of the Saratov Reservoir Plant subject to the requirements for materials, installed equipment and capacity of the silo.

Nozzle schedule of steel silo with capacity of 115 m3

| Designation | Assignment | Nominal inside diameter DN, mm | Pressure Pnom, MPa |

|---|---|---|---|

| A | product inlet | 500х500 | - |

| В | vent pipe | 100 | 0,6 |

| С | product outlet | 470х470 | - |

| Е | reserve | 50 | 1,6 |

| F | reserve | 50 | 1,6 |

| G | level controller | 50 | 1,6 |

| Н | pick level indicator | 50 | 1,6 |

| МН1 | upper manhole | 400 | 0,6 |

| МН2 | side manhole | 600х600 | 0,6 |

| I | sampling equipment | 80 | 1,6 |

*These specifications are for reference only and may differ from the values given in the project.

Advantages of silos for granular materials manufactured by SARRZ

- Silos design meets the necessary technological requirements of the Customer.

- Exact observance of dates of manufacture and shipment to the facility.

- The wide partner network allows to deliver silos to any region of Russia.

- There is no additional margin, as production and delivery are carried out directly by the manufacturer.

How to buy silos for granular materials?

You may order a silo for storage of granular materials from SARRZ in one of the following ways:

- call at +7(8452)250-288 (throughout Russia)

- call at +7(8452)250-288 (for Saratov and Saratov region)

- e-mail specifications or technical enquiry at

- use the form "Request for quotation", provide contact information, and our specialist will contact you

See also:

| Rectangular tanks | Silos for granular materials | Silos for liquids |

| Silos for bulk materials | Surge tanks | Non-pressure tanks |

| Pressure tanks | Hot wells | Tanks for CHP-plants, NPGS and HPP |

| Stainless steel tanks |