Non-pressure tanks

Description

Non-pressure tanks are used for storage and delivery of water and various technical non-aggressive liquids to technological systems under loading, that is, without pressure.

Production of non-pressure tanks at SARRZ

The Saratov Reservoir Plant manufactures non-pressure tanks with a volume up to 32 m3 in vertical and horizontal design, depending on the project binding at the facility.

Depending on the technical characteristics and operating conditions the shell and the bottoms are made of carbon or alloy steel with a thickness of 4-8 mm or stainless steel with a thickness of 3-6 mm. For service life extension the thickness is designed taking into account corrosion allowance.

Technical specification of the non-pressure tanks

| Criteria | Value | ||

|---|---|---|---|

| Processing medium | water and other non-aggressive liquids | ||

| Design |

|

||

| Volume, m3 | 0.1-32 (100 - 32000 l) | ||

| Processing pressure | atmospheric | ||

| Medium temperature, ºС | 0...+100 | ||

| Climatic category | NF 3 | ||

| Seismic activity at the operational site | up to 7 (up to 9 upon special order) | ||

| Material design of structural points | М1 | St3, St20 | |

| М2 | 09G2S, St3, St20 | ||

| М2 | AISI 304, 12Х18Н10Т, 12Х18Н9Т, 12Х15G9ND, St3, St20 | ||

| Service life, years | М1 | 10-15 | |

| М2 | 15-20 | ||

| М3 | 30-40 | ||

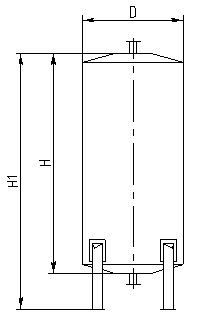

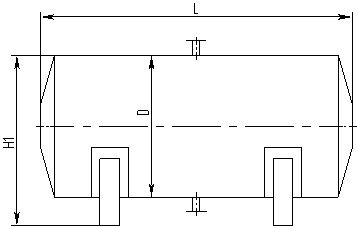

Vertical and horizontal non-pressure tanks structural design

Structurally, the tanks are a cylindrical shell with flat or conical bottoms. At a site they are installed on supports, the number of which is determined by the technical requirements.

Structurally, the tanks are a cylindrical shell with flat or conical bottoms. At a site they are installed on supports, the number of which is determined by the technical requirements.

If necessary, heating/cooling and maintaining the desired temperature of the processing medium, the shell may be equipped with an internal or external coil or steam jacket.

In a typical arrangement the shell and bottoms are provided with inlet and outlet fittings of the operating medium and fittings for drainage and overflow. The layout and diameters of the nozzles and fittings are calculated according to the design.

In agreement with the Customer, additional equipment may be provided:

- coolant supply and discharge fittings (if jacket is available)

- quartz tube as level indicator

- measuring tube

- breathing tube

- recirculation nozzle

- fittings for Instrumentation devices installation

- surge line fitting

- blade mixers for operating medium with viscosity up to 50 PA x s

- assembly cover

| Vertical non-pressure tanks | Horizontal non-pressure tank |

|---|---|

|

|

Dimensional specifications of vertical non-pressure tanks*

| Volume, m3 | Diameter, D, mm | Height, H, mm | Height with supports, H1, mm | Weight, version М1(М2)/М3, kg |

|---|---|---|---|---|

| 0.10 | 400 | 800 | 1000 | 54/49 |

| 0.125 | 400 | 1000 | 1200 | 65/55 |

| 0.16 | 500 | 850 | 1050 | 67/57 |

| 0.20 | 500 | 1050 | 1250 | 77/65 |

| 0.25 | 600 | 900 | 1100 | 80/67 |

| 0.32 | 600 | 1150 | 1350 | 95/78 |

| 0.40 | 700 | 1050 | 1250 | 103/85 |

| 0.50 | 800 | 1100 | 1300 | 170/148 |

| 0.63 | 800 | 1350 | 1550 | 193/165 |

| 0.80 | 900 | 1350 | 1550 | 215/184 |

| 1.0 | 900 | 1650 | 1900 | 242/205 |

| 1.25 | 1000 | 1700 | 1950 | 270/228 |

| 1.6 | 1100 | 1800 | 2050 | 360/315 |

| 2.0 | 1200 | 1900 | 2150 | 415/360 |

| 2.5 | 1300 | 2050 | 2300 | 470/405 |

| 3.2 | 1400 | 2250 | 2500 | 545/475 |

| 4.0 | 1500 | 2450 | 2700 | 660/570 |

| 5.0 | 1600 | 2650 | 2900 | 850/650 |

| 6.3 | 1700 | 3000 | 3300 | 1020/905 |

| 8.0 | 1800 | 3350 | 3650 | 1190/1050 |

| 10 | 1900 | 3750 | 4050 | 1370/1205 |

| 12.5 | 2000 | 4250 | 4550 | 1595/1400 |

| 16 | 2200 | 4500 | 4800 | 1850/1625 |

| 20 | 2400 | 4750 | 5050 | 2145/1890 |

| 25 | 2400 | 5850 | 6200 | 2545/2230 |

| 32 | 2500 | 6850 | 7200 | 3135/2740 |

Dimensional specifications of horizontal non-pressure tanks*

| Volume, m3 | Diemeter, D, mm | Length, L, mm | Height with supports, H1, mm | Weight, version М1(М2)/М3, kg |

|---|---|---|---|---|

| 0.10 | 400 | 800 | 600 | 65/57 |

| 0.125 | 400 | 1000 | 600 | 74/65 |

| 0.16 | 500 | 850 | 700 | 77/67 |

| 0.20 | 500 | 1050 | 700 | 90/78 |

| 0.25 | 600 | 900 | 800 | 94/81 |

| 0.32 | 600 | 1150 | 800 | 117/100 |

| 0.40 | 700 | 1050 | 900 | 125/107 |

| 0.50 | 800 | 1100 | 1000 | 180/157 |

| 0.63 | 800 | 1350 | 1000 | 205/175 |

| 0.80 | 900 | 1350 | 1100 | 225/195 |

| 1.0 | 900 | 1650 | 1100 | 260/225 |

| 1.25 | 1000 | 1700 | 120 | 300/260 |

| 1.6 | 1100 | 1800 | 1300 | 390/345 |

| 2.0 | 1200 | 1900 | 1400 | 510/455 |

| 2.5 | 1300 | 2050 | 1500 | 580/520 |

| 3.2 | 1400 | 2250 | 1600 | 655/585 |

| 4.0 | 1500 | 2450 | 1700 | 775/690 |

| 5.0 | 1600 | 2650 | 1800 | 985/790 |

| 6.3 | 1700 | 3000 | 1950 | 1175/1060 |

| 8.0 | 1800 | 3350 | 2050 | 1355/1220 |

| 10 | 1900 | 3750 | 2150 | 1560/1395 |

| 12.5 | 2000 | 4250 | 2250 | 1815/1620 |

| 16 | 2200 | 4500 | 2500 | 2060/1835 |

| 20 | 2400 | 4750 | 2700 | 2425/2170 |

| 25 | 2400 | 5850 | 2700 | 3015/2690 |

| 32 | 2500 | 6850 | 2800 | 3560/3170 |

*The Plant produces non-pressure tanks and containers of any size and any configuration per individual enquiry

How to buy non-pressure tank?

Non-pressure tank may be ordered from the representatives of the Plant SARRZ in one of the following ways:

- call at +7(8452)250-288 for all regions

- send operating requirements or Technical specification at e-mail

- use the form "Request for quotation", provide contact information, and our specialist will contact you

See also:

| Rectangular tanks | Silos for granular materials | Silos for liquids |

| Silos for bulk materials | Surge tanks | Non-pressure tanks |

| Pressure tanks | Hot wells | Tanks for CHP-plants, NPGS and HPP |

| Stainless steel tanks |