Vertical apparatus with conic head and flat top head (VKP), with/without coil

Description

Vertical apparatus with conic head and flat top head (VKP) are used to store liquid operational product at atmospheric pressure, and also as sedimentation tanks. They can be used with non-explosive, and non-toxic liquids of 3 and 4 hazard classes (in accordance with the classification in GOST 12.1.004-76).

Operating conditions

- working environment - oil products, fuels and lubricants, oils, food products, chemicals

- density - up to 2000 kg/m3

- nominal pressure - up to 0.07 MPa

- pressure in the coil (if available) - up to 0.6 MPa

- ambient temperature - from -60ºС to +50ºС

- only aboveground accommodation

Construction of all-welded vertical vessel with conic head and flat top head

They are an all-welded vertical cylindrical housing with a conical underscored head and flat top head which is mounted on lug- or leg-supports. There are fittings that are provided in the shells for the installation of technological equipment - level gauge, thermometer, pressure gauge, safety valve, pump, etc.

Vessels can be manufactured with a coil - an integrated tubular preheater designed for heating, if product viscosity is too large to drain at low temperatures. The preheated water is used as the heat carrier, which is supplied to the heat exchanger at a pressure of up to 0.6 MPa.

The conical head is very convenient for draining liquids from the lower part by gravity. They can be manufactured with angles of 60º, 90º or 140º. Unmapped heads are used for operation up to 0.07 MPa.

Commond terms to order at the Saratov Reservoir Plant

Vertical apparatus-1-1(4)-25-0 is a vertical vessel with a conical head and flat top head, all-welded (1), without a "jacket" (1) / with a "jacket" (4), 25 m3, at atmospheric nominal pressure

Manufacture of all-welded vertical apparatus with conic head and flat top head

The Saratov Reservoir Plant has the necessary Certificates of Conformity for the production of tanks and vessels for various purposes.

We produce vertical apparatus VKP from low-alloyed (09G2S, 16GS, 10G2), carbon (St3sp), acid-resistant (12Kh18N10T, 10X17N13M2T, 10X17N13M3T and 06HN28MDT) steel grades. Choice of material depends on the characteristics of the work product and operating conditions.

Vertical vessels VKP are manufactured with or without a coil with a volume of 10 m3, 16 m3 and 25 m3.

Their production is carried out on the basis of at the Сustomer's request for equipment and a filled in Questionnaire.

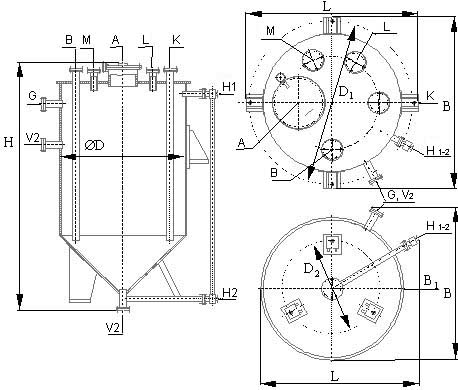

Drawing of VKP without heating coil

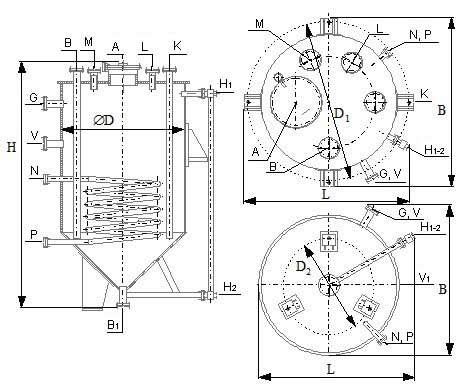

Drawing of VKP with heating coil

Nozzle schedule

(location and application of the fittings may vary depending on your order)

| Designation | Application |

|---|---|

| А | hatch |

| B | product inlet |

| V | product outlet |

| G | overtop |

| H | for the column of tubular level gauge |

| K | for level gauge |

| L | for thermometer |

| M | reserve |

| N | coolant inlet |

| P | coolant outlet |

Overall size of Vertical apparatus VKP

| Volume, м3 | D, mm | D | d | D | d | D1 | D1 | Overall size, mm | Weight, kg | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | L | B | H | with coil | without coil | |||

| Apparatus on lug supports | |||||||||||||

| 10 | 2200 | 2570 | 35 | - | - | - | 2010 | 2690 | 2690 | 3825 | 2120 | 2040 | |

| 16 | 2600 | 3125 | 42 | - | - | - | 2410 | 3255 | 3255 | 4325 | 3395 | 3305 | |

| 25 | 2800 | 3490 | 42 | - | - | - | 2610 | 3620 | 3620 | 5525 | 4770 | 4680 | |

| Apparatus on leg supports | |||||||||||||

| 10 | 2200 | - | - | 2010 | 35 | 2570 | - | 2360 | 2365 | 3825 | 2120 | 2040 | |

| 16 | 2600 | - | - | 2410 | 42 | 3125 | - | 2730 | 2740 | 4325 | 3370 | 3280 | |

| 25 | 2800 | - | - | 2610 | 42 | 3490 | - | 2920 | 2925 | 5525 | 4770 | 4680 | |

The summary table of technical characteristics of vessels of various types can be found here.

Ordering of a all-welded vertical apparatus with conic heads and flat top head at Saratov Reservoir Plant

To calculate the cost of Vertical vessel VKP manufacturing, which includes the selection of equipment, structural design, steel structures details developing (at the Сustomer's request, metal structures developing) and the production of the vessel itself, You can:

- call at 8-800-555-9480

- fill in the Questionnaire and send it at the e-mail

- use the "Request for quotation" form, provide contact information for contacting you

We also carry out the delivery to the place of operation across Russia and near abroad. If required we provide installation services.

See also: