Vertical apparatus with conic heads (VKK)

Description

Vertical apparatus with conic heads VKK are used in oil and gas, chemical or food industries for receiving, storing and dispensing liquid operational product. The product is stored at a pressure of up to 0.7 MPa. Product is dispensed by gravity flow.

Construction of Vertical bulk capacity vessels with conic heads

It’s an apparatus with all-welded vertical cylindrical body and conic heads and hatch cover.

There are technological hatches and openings for installing equipment, filling and draining the liquid and input/output of steam and condensate on the shell.

Technological equipment is selected according to the individual order, depending on the purpose and operating conditions. At the Customer's request, the equipment may include detectors of the upper and lower levels, temperature, pressure detectors, etc.

Shells and heads can be thermally insulated, and a heat exchanger can be installed inside to maintain the operating temperature.

Thermal insulation can be made of rock wool board and protective cover, as well as polyurethane foam, that’s a modern and reliable means with additional anti-corrosive protection of the external surface.

Heaters and heat exchangers are selected on the basis of ATC 24.218.07-90 "External and internal heat exchangers for vessels and apparatus." General technical specification".

This type of vessels is installed vertically on metal supports, the height of which is calculated during the design development.

Manufacture of Vertical apparatus with conic heads at Saratov Reservoir Plant

The Saratov Reservoir Plant has the necessary Certificates of Conformity for the production of vessels of any sizes and purpose.

Vertical vessels VKK are made of various materials based on operating conditions and environmental characteristics:

- stainless steel 12Х18Н10Т

- stainless steel AISI 304, Russian analogue 08H18N10

- low-alloyed grades 09G2S, 16GS, 10G2

- carbon steel St3sp

All welded seams are made by semi-automatic welding. At the end of the work, weld inspection is carried out in accordance with the production program. Hydraulic tests are carried out to check the tightness.

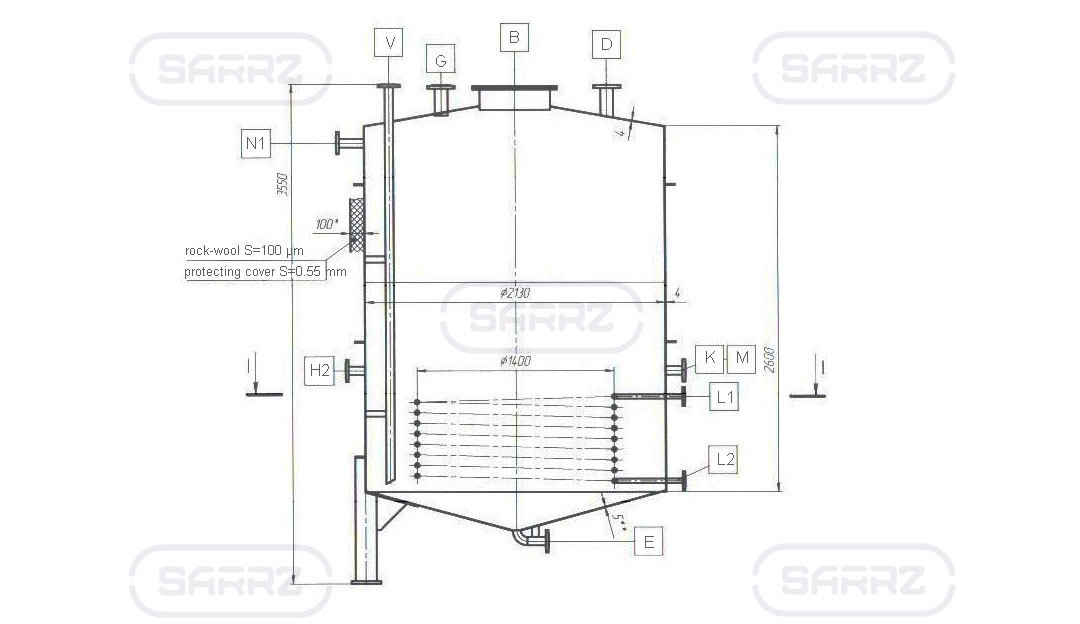

The Saratov Reservoir Plant produces VKK in any complete sets. Below you can see the drawing of vertical vessel VKK, designed for storing of fat.

VKK drawing with a volme of 9 m3

Nozzle schedule

| Designation | Application | Diameter, mm | Pressure, MPa | Outreach of nozzles, mm |

|---|---|---|---|---|

| B | hatch | 500 | - | 200 |

| V | product inlet | 50 | 1,6 | 200 |

| E | product outlet | 50 | 1,6 | 200 |

| D | air vent | 50 | 0,25 | 200 |

| G | for steaming | 100 | 1,6 | 200 |

| H1 | for top level gauge | 50 | 1,6 | 200 |

| H2 | for lower level gauge | 50 | 1,6 | 200 |

| K | for temperature detector | 50 | 1,6 | 200 |

| L1 | steam inlet | 25 | 1,6 | 150 |

| L2 | condensate outlet | 25 | 1,6 | 150 |

| M | for pressure detector | 50 | 1,6 | 150 |

Technical characteristics* of Vertical apparatus with conic heads with a volume of 9 m3

| № | Parameters | Value |

|---|---|---|

| 1 | Nominal volume, m3 | 9 |

| 2 | Heads | conic |

| 3 | Operational product density, kg/m3 | up to 950 |

| 4 | Shell maximum temperature, ºС | +70 |

| 5 | Internal extra pressure | for filling |

| 6 | Shell minimum temperature, ºС | -35 |

| 7 | Expected service life, years | 20 |

| 8 | Steel grade of main constructions | AISI 304 |

| 9 | Heat exchanger | if required |

| 10 | Thermal insulation | if required |

| 11 | Overall size, mm ( Diameter x Height with heads) | 2130х3550 |

*drawing, characteristics, location and application of the fittings may differ and are given for reference

The summary table of technical characteristics of bulk capacity vessels of different types you can found here.

How to find out the cost of the vertical vessels with conic heads of our production?

The cost depends on the volume, design (with / without heater, with thermal insulation / without) and operating conditions.

In order to calculate the price of a vertical apparatus with conic heads, You can:

- call at 8-800-555-9480

- fill in Questionnaire and send it at e-mail

- use the "Request for quotation" form, provide contact information for contacting you

Specialists of the Plant perform package of services on design and construction of oil industry facilities at prices without intermediaries.

See also: