Vertical apparatus with elliptical heads (VEE)

Description

Vertical bulk capacity vessels and apparatus are used for receiving, storing and dispensing liquid and gaseous media (including harmful, explosive and fire hazardous substances) in oil, chemical and gas industries. They can also be used as sedimentation tanks.

The Saratov Reservoir Plant produces vessels VEE with elliptical heads of 1 m3, 2 m3, 3.2 m3, 5 m3, 6.3 m3, 10 m3, 16 m3, 25 m3.

They are operated at conditional pressure 0,6; 1.0 and 1.6 MPa (6, 10 and 16 kgs/ sm2). The density of the stored product should not exceed 1600 kg / m3. Operating temperature is up to 300°C.

The discharge of the operational product may occur in two ways: by gravity or by the medium pressurized with compressed air, inert or process gas.

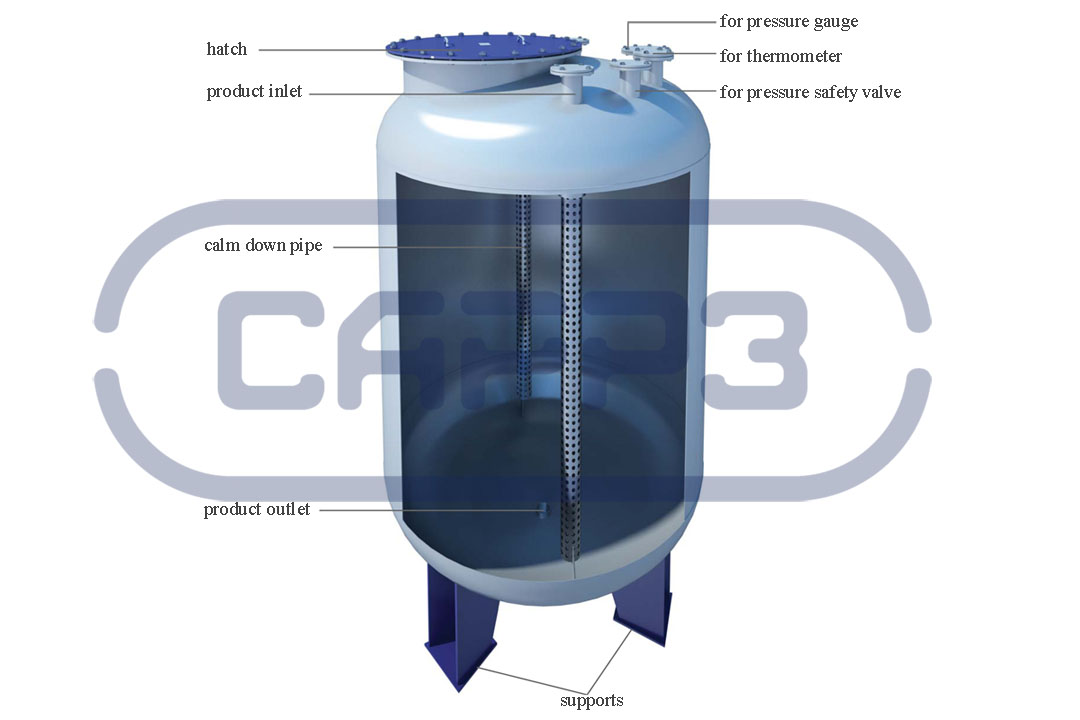

Construction of all-welded vertical vessels with elliptical heads

This type of apparatus is all-welded cylindrical vessel with elliptical heads.

Fittings and nozzles are provided in the housing to receive and discharge of the operating product, hatches for inspection and repair, as well as devices to install (control and measuring instruments, dispensing equipment, safety valves, etc.).

The vessels are mounted on lug- and leg-supports at the site. The choice of the supports type is based on the operational conditions and overall sizes. (see the tables)

Manufacture of all-welded vertical apparatus with elliptical heads

The Saratov Reservoir Plant has the necessary Certificates of Conformity for the production of tanks and vessels of various purposes.

Apparatus VEE are manufactured from various steel grades: St3sp5; 16GS; 09G2S2С; 12х18НХ10Т; 10Х17Н13М2Т, 16GS-6 + 12Х18Н10Т and 16GS-6 + 10Х17Н13М2Т.

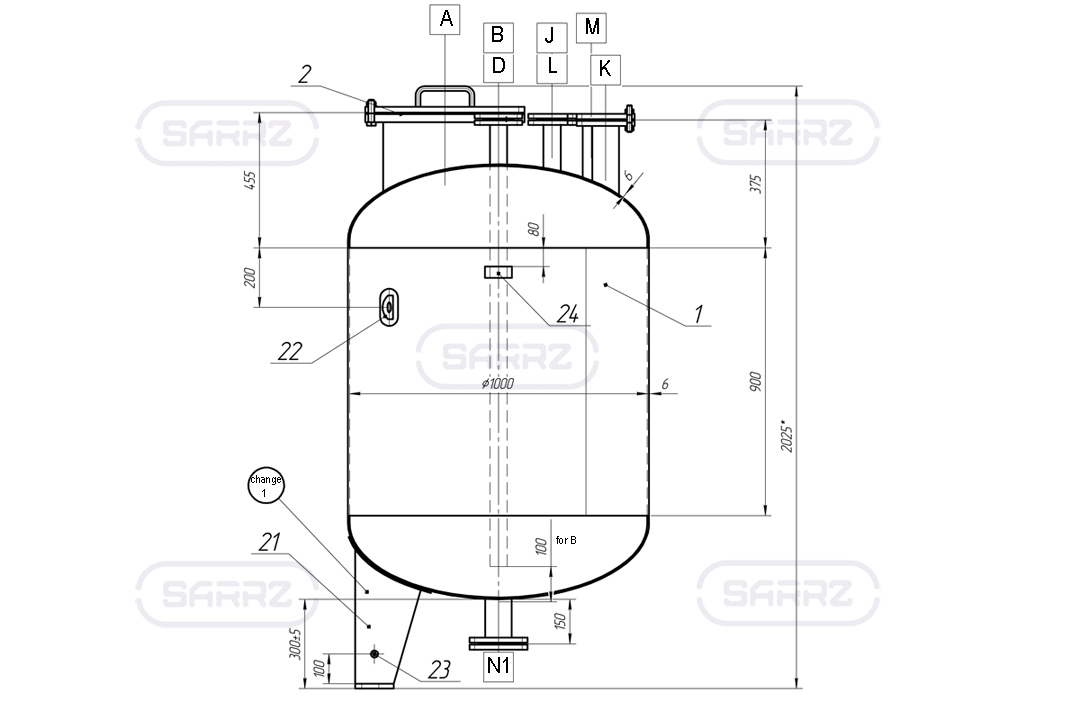

Drawing of all-welded vertical vessel with elliptical heads of volume 0,6 m3

Nozzle schedule

| Designation | Application | Nominal bore, mm |

|---|---|---|

| А | hatch | 400 |

| B | product inlet | 50 |

| N1 | product outlet | 80 |

| D | reserve | 50 |

| J | for pressure gauge | 50 |

| K | for level gauge | 80 |

| L | for thermometer | 50 |

| M | air vent | 50 |

Overall size of all-welded vertical apparatus with elliptical heads

| Volume, m3 | Nominal pressure, MPa | Sizes | Designation | ||||

|---|---|---|---|---|---|---|---|

| nominal | oparating (up to) | D | h | l (up to) | n | ||

| 1 | 0,91 | 0,6(6) | 1000 | 900 | 160 | - | VEE1-1-0,6 |

| 1(10) | VEE1-1-1,0 | ||||||

| 1,6(16) | VEE1-1-1,6 | ||||||

| 2 | 1,74 | 0,6(6) | 1200 | 1250 | 185 | 4 | VEE1-2-0,6 |

| 1(10) | VEE1-2-1,0 | ||||||

| 1,6(16) | VEE1-2-1,6 | ||||||

| 3,2 | 3 | 0,6(6) | 1400 | 1600 | 200 | VEE1-3,2-0,6 | |

| 1(10) | VEE1-3,2-1,0 | ||||||

| 1,6(16) | VEE1-3,2-1,6 | ||||||

| 5 | 4,3 | 0,6(6) | 1600 | 1800 | 250 | 4 | VEE1-5-0,6 |

| 1(10) | VEE1-5-1,0 | ||||||

| 1,6(16) | VEE1-5-1,6 | ||||||

| 6,3 | 5,6 | 0,6(6) | 1600 | 2500 | 250 | VEE1-6,3-0,6 | |

| 1(10) | VEE1-6,3-1,0 | ||||||

| 1,6(16) | VEE1-6,3-1,6 | ||||||

| 10 | 9,2 | 0,6(6) | 2000 | 320 | 8 | VEE1-10-0,6 | |

| 1(10) | VEE1-10-1,0 | ||||||

| 1,6(16) | VEE1-10-1,6 | ||||||

| 16 | 15,5 | 0,6(6) | 4500 | VEE1-16-0,6 | |||

| 1(10) | VEE1-16-1,0 | ||||||

| 1,6(16) | VEE1-16-1,6 | ||||||

| 25 | 22,9 | 0,6(6) | 2400 | 340 | VEE1-25-0,6 | ||

| 1(10) | VEE1-25-1,0 | ||||||

| 1,6(16) | VEE1-25-1,6 | ||||||

Technical characteristics of all-welded vertical vessels with elliptical heads on lug-supports

(the information is for reference only and may differ)

| Designation | NUMBER OF MATERIAL PERFORMANCE | S/S1 | D1 | d1 | L | B | Total weight, kg |

|---|---|---|---|---|---|---|---|

| VEE-1-1-1-0,6 | 1 | 6/6 | 1210 | 24 | 1250 | 1315 | 440 |

| 2 | |||||||

| 3 | 435 | ||||||

| 5 | 8/8 | 1220 | 1260 | 1320 | 520 | ||

| 6 | |||||||

| VEE-1-1-1-1,0 | 2 | 6/8 | 1210 | 1250 | 1315 | 500 | |

| 3 | 8/8 | 1220 | 1260 | 1320 | 545 | ||

| 4 | 6/6 | 1210 | 1250 | 1315 | 465 | ||

| 5 | 8/10 | 1220 | 1260 | 1320 | 580 | ||

| 6 | 8/8 | 540 | |||||

| VEE-1-1-1-1,6 | 2 | 8/10 | 620 | ||||

| 3 | 605 | ||||||

| 4 | 600 | ||||||

| 5 | 10/12 | 1230 | 1270 | 695 | |||

| 6 | |||||||

| VEE-1-1-2-0,6 | 2 | 6/6 | 1442 | 24 | 1535 | 1540 | 610 |

| 3 | 605 | ||||||

| 4 | 1545 | ||||||

| 5 | 8/8 | 1445 | 735 | ||||

| 6 | |||||||

| VEE-1-1-2-1,0 | 2 | 760 | |||||

| 3 | |||||||

| 4 | 6/8 | 1442 | 1540 | 680 | |||

| 5 | 10/10 | 1445 | 1545 | 1545 | 90 | ||

| 6 | 8/10 | 1535 | 820 | ||||

| VEE-1-1-2-1,6 | 1 | 10/12 | 1455 | 1545 | 990 | ||

| 2 | |||||||

| 3 | 975 | ||||||

| 4 | 8/10 | 1445 | 835 | ||||

| 5 | 12/14 | 1465 | 1555 | 1555 | 1110 | ||

| 6 | 10/14 | 1455 | 1545 | 1545 | 1030 | ||

| VEE-1-1-3,2-0,6 | 2 | 6/8 | 1645 | 1735 | 1735 | 870 | |

| 3 | 860 | ||||||

| 4 | |||||||

| 5 | 8/10 | 1655 | 1740 | 1740 | 1050 | ||

| 6 | 8/8 | 1648 | 980 | ||||

| VEE-1-1-3,2-0,6 | 2 | 8/10 | 1080 | ||||

| 3 | 1070 | ||||||

| 4 | 8/8 | 1000 | |||||

| 5 | 10/12 | 1655 | 1745 | 1745 | 1270 | ||

| 6 | 10/10 | 1190 | |||||

| VEE-1-1-3,2-1,6 | 2 | 10/12 | 1310 | ||||

| 3 | 12/12 | 1755 | 1755 | 1400 | |||

| 4 | 10/12 | 1745 | 1745 | 1270 | |||

| 5 | 14/16 | 1670 | 1760 | 1760 | 1690 | ||

| 6 | 12/14 | 1655 | 1755 | 1755 | 1480 | ||

| VEE-1-1-5-0,6 | 1 | 8/8 | 1910 | 35 | 2000 | 2000 | 1360 |

| 2 | 1350 | ||||||

| 3 | 1340 | ||||||

| 4 | 6/8 | 1905 | 1995 | 1995 | 1190 | ||

| 5 | 10/10 | 1915 | 2005 | 2005 | 1580 | ||

| 6 | |||||||

| VEE-1-1-5-1,0 | 2 | 1630 | |||||

| 3 | |||||||

| 4 | 8/8 | 1910 | 2025 | 2025 | 1380 | ||

| 5 | 12/12 | 1925 | 2015 | 2015 | 1880 | ||

| 6 | 10/10 | 1915 | 2005 | 2005 | 1620 | ||

| VEE-1-1-5-1,6 | 2 | 12/14 | 1925 | 2015 | 2015 | 2030 | |

| 3 | 2010 | ||||||

| 4 | 10/12 | 1915 | 2005 | 2005 | 1750 | ||

| 5 | 14/18 | 1935 | 2025 | 2025 | 2410 | ||

| 6 | 12/15 | 1925 | 2015 | 2015 | 2110 | ||

| VEE-1-1-6,3-0,6 | 1 | 8/8 | 1910 | 2000 | 2000 | 1590 | |

| 2 | |||||||

| 3 | 1580 | ||||||

| 4 | 8/8 | 1570 | |||||

| 5 | 10/10 | 2005 | 2005 | 1870 | |||

| 6 | |||||||

| VEE-1-1-6,3-1,0 | 2 | 10/10 | 1915 | 1940 | |||

| 3 | 1930 | ||||||

| 4 | 8/8 | 1910 | 2000 | 2000 | 1620 | ||

| 5 | 12/12 | 1925 | 2015 | 2015 | 2230 | ||

| 6 | 10/12 | 1915 | 2005 | 2005 | 2020 | ||

| VEE-1-1-6,3-1,6 | 2 | 12/14 | 1925 | 2015 | 2015 | 2380 | |

| 3 | 2360 | ||||||

| 4 | 10/12 | 1915 | 2005 | 2005 | 2050 | ||

| 5 | 16/18 | 1940 | 2030 | 2030 | 3000 | ||

| 6 | 14/16 | 1935 | 2025 | 2025 | 2670 | ||

| VEE-1-1-10-0,6 | 2 | 8/10 | 2370 | 2490 | 2490 | 2230 | |

| 3 | |||||||

| 4 | 2220 | ||||||

| 5 | 10/10 | 2375 | 2495 | 2495 | 2490 | ||

| 6 | 2480 | ||||||

| VEE-1-1-10-1,0 | 2 | 10/12 | 2375 | 2495 | 2495 | 2690 | |

| 3 | 2680 | ||||||

| 4 | 10/10 | 2520 | |||||

| 5 | 14/14 | 2390 | 2510 | 2510 | 3390 | ||

| 6 | 12/14 | 2385 | 2505 | 2505 | 3110 | ||

| VEE-1-1-10-1,6 | 2 | 14/16 | 2390 | 2510 | 2510 | 3590 | |

| 3 | 3570 | ||||||

| 4 | 12/14 | 2385 | 2505 | 2505 | 3140 | ||

| 5 | 18/20 | 2410 | 2530 | 2530 | 4550 | ||

| 6 | 16/18 | 2400 | 2520 | 2520 | 3970 | ||

| VEE-1-1-16-0,6 | 1 | 10/10 | 2525 | 42 | 2655 | 2655 | 2740 |

| 2 | |||||||

| 3 | 3720 | ||||||

| 4 | 8/10 | 2520 | 2650 | 2650 | 3260 | ||

| 5 | 12/12 | 2535 | 2665 | 2665 | 4320 | ||

| 6 | 10/10 | 2525 | 2655 | 2655 | 3720 | ||

| VEE-1-1-16-1,0 | 2 | 2665 | 2665 | 3940 | |||

| 3 | 10/12 | 2535 | |||||

| 4 | 10/10 | 2525 | 2655 | 2655 | 3780 | ||

| 5 | 14/14 | 2540 | 2670 | 2670 | 5080 | ||

| 6 | 12/14 | 2535 | 2665 | 2665 | 4580 | ||

| VEE-1-1-16-1,6 | 2 | 14/16 | 2540 | 2670 | 2670 | 5300 | |

| 3 | 14/18 | 5400 | |||||

| 4 | 12/14 | 2535 | 2665 | 2665 | 4630 | ||

| 5 | 18/22 | 2555 | 2685 | 2685 | 6700 | ||

| 6 | 16/18 | 2580 | 2680 | 2680 | 5890 | ||

| VEE-1-1-25-0,6 | 2 | 10/10 | 3090 | 3220 | 3220 | 5220 | |

| 3 | 5200 | ||||||

| 4 | 5180 | ||||||

| 5 | 12/12 | 3095 | 3225 | 3225 | 5970 | ||

| 6 | 10/12 | 3090 | 3220 | 3220 | 5430 | ||

| VEE-1-1-25-1,0 | 2 | 12/14 | 3095 | 3225 | 3225 | 6270 | |

| 3 | 6260 | ||||||

| 4 | 10/12 | 3090 | 3220 | 3220 | 5490 | ||

| 5 | 16/18 | 3110 | 3240 | 3240 | 7840 | ||

| 6 | 14/16 | 3105 | 3235 | 3235 | 7080 | ||

| VEE-1-1-25-1,6 | 2 | 10/20 | 3110 | 3240 | 3240 | 8170 | |

| 3 | 8160 | ||||||

| 4 | 14/16 | 3105 | 3235 | 3235 | 7160 | ||

| 5 | 22/24 | 3265 | 3265 | 10440 | |||

| 6 | 22/24 | 3135 | 3250 | 3250 | 8980 |

Technical characteristics of all-welded vertical vessels with elliptical heads on leg-supports

| Designation | NUMBER OF MATERIAL PERFORMANCE | S/S1 | D1 | d2 | L | B | H | Total weight, kg |

|---|---|---|---|---|---|---|---|---|

| VEE-1-1-1-0,6 | 1 | 6/6 | 920 | 19 | 1140 | 1200 | 1965 | 445 |

| 2 | ||||||||

| 3 | 1985 | 40 | ||||||

| 5 | 8/8 | 1145 | 525 | |||||

| 6 | ||||||||

| VEE-1-1-1-1,0 | 2 | 6/8 | 1140 | 1970 | 505 | |||

| 3 | 8/8 | 1145 | 1990 | 550 | ||||

| 4 | 6/6 | 1140 | 465 | |||||

| 5 | 8/10 | 1145 | 585 | |||||

| 6 | 8/8 | 550 | ||||||

| VEE-1-1-1-1,6 | 2 | 8/10 | 2260 | 625 | ||||

| 3 | 1950 | 610 | ||||||

| 4 | 605 | |||||||

| 5 | 10/12 | 1205 | 1980 | 700 | ||||

| 6 | ||||||||

| VEE-1-1-2-0,6 | 2 | 6/6 | 1100 | 24 | 1335 | 1385 | 2370 | 630 |

| 3 | 2390 | 625 | ||||||

| 4 | ||||||||

| 5 | 8/8 | 755 | ||||||

| 6 | ||||||||

| VEE-1-1-2-1,0 | 2 | 2390 | 780 | |||||

| 3 | ||||||||

| 4 | 6/8 | 700 | ||||||

| 5 | 10/10 | 1340 | 1390 | 920 | ||||

| 6 | 8/10 | 1335 | 1385 | 840 | ||||

| VEE-1-1-2-1,6 | 1 | 10/12 | 1350 | 1390 | 2715 | 1020 | ||

| 2 | ||||||||

| 3 | 2405 | 990 | ||||||

| 4 | 8/10 | 1385 | 2400 | 850 | ||||

| 5 | 12/14 | 1390 | 2410 | 1130 | ||||

| 6 | 10/14 | 1050 | ||||||

| VEE-1-1-3,2-0,6 | 2 | 6/8 | 1260 | 24 | 1520 | 1570 | 2870 | 890 |

| 3 | 2885 | 880 | ||||||

| 4 | ||||||||

| 5 | 8/10 | 1575 | 1070 | |||||

| 6 | 8/8 | 1570 | 1000 | |||||

| VEE-1-1-3,2-1,0 | 2 | 8/10 | 2875 | 1100 | ||||

| 3 | 2895 | |||||||

| 4 | 8/8 | 1020 | ||||||

| 5 | 10/12 | 1575 | 1290 | |||||

| 6 | 10/10 | 1210 | ||||||

| VEE-1-1-3,2-1,6 | 2 | 10/12 | 1530 | 1575 | 3165 | 1330 | ||

| 3 | 12/12 | 1535 | 2855 | 1420 | ||||

| 4 | 10/12 | 1530 | 1300 | |||||

| 5 | 1416 | 1535 | 1700 | |||||

| 6 | 12/14 | 1510 | ||||||

| VEE-1-1-5-0,6 | 1 | 8/8 | 1410 | 35 | 1755 | 1760 | 3445 | 1380 |

| 2 | ||||||||

| 3 | 3155 | 1360 | ||||||

| 4 | 6/8 | 1210 | ||||||

| 5 | 1765 | 1610 | ||||||

| 6 | 10/10 | |||||||

| VEE-1-1-5-1,0 | 2 | 3445 | 1660 | |||||

| 3 | 3475 | 1640 | ||||||

| 4 | 8/8 | 1760 | 1400 | |||||

| 5 | 12/12 | 1760 | 1765 | 3480 | 1900 | |||

| 6 | 10/10 | 1755 | 1650 | |||||

| VEE-1-1-5-1,6 | 2 | 12/14 | 1765 | 1765 | 3450 | 2060 | ||

| 3 | 2030 | |||||||

| 4 | 10/12 | 1760 | 3480 | 1770 | ||||

| 5 | 14/18 | 1765 | 1770 | 3530 | 2430 | |||

| 6 | 12/15 | 1765 | 3485 | 2140 | ||||

| VEE-1-1-6,3-0,6 | 1 | 8/8 | 1755 | 1760 | 4260 | 1670 | ||

| 2 | ||||||||

| 3 | 3965 | 1650 | ||||||

| 4 | 1640 | |||||||

| 5 | 10/10 | 1765 | 3970 | 1950 | ||||

| 6 | ||||||||

| VEE-1-1-6,3-1,0 | 2 | 4160 | 2010 | |||||

| 3 | 4190 | 2000 | ||||||

| 4 | 8/8 | 1760 | 1700 | |||||

| 5 | 12/12 | 1760 | 1765 | 4295 | 2300 | |||

| 6 | 10/12 | 1755 | 2090 | |||||

| VEE-1-1-6,3-1,6 | 2 | 12/14 | 1765 | 1760 | 4265 | 2470 | ||

| 3 | 4295 | 2440 | ||||||

| 4 | 10/12 | 1760 | 2130 | |||||

| 5 | 16/18 | 1765 | 1770 | 4325 | 3080 | |||

| 6 | 14/16 | 4300 | 2730 | |||||

| VEE-1-1-10-0,6 | 2 | 8/10 | 1810 | 42 | 2130 | 2125 | 4455 | 2430 |

| 3 | 4160 | |||||||

| 4 | 2410 | |||||||

| 5 | 10/10 | 2680 | ||||||

| 6 | ||||||||

| VEE-1-1-10-1,0 | 2 | 10/12 | 1810 | 42 | 2130 | 2125 | 4455 | 2890 |

| 3 | 4485 | |||||||

| 4 | 10/10 | 2720 | ||||||

| 5 | 14/14 | 2135 | 2130 | 4535 | 3590 | |||

| 6 | 12/14 | 3330 | ||||||

| VEE-1-1-10-1,6 | 2 | 14/16 | 4515 | 3790 | ||||

| 3 | 4545 | 3780 | ||||||

| 4 | 12/14 | 4535 | 3370 | |||||

| 5 | 18/20 | 2140 | 2135 | 4555 | 4630 | |||

| 6 | 16/18 | 4550 | 4190 | |||||

| VEE-1-1-16-0,6 | 1 | 10/10 | 2130 | 2125 | 6655 | 4090 | ||

| 2 | ||||||||

| 3 | 6365 | 4080 | ||||||

| 4 | 8/10 | 3600 | ||||||

| 5 | 12/12 | 2135 | 2130 | 4660 | ||||

| 6 | 10/10 | 2130 | 2125 | 4060 | ||||

| VEE-1-1-10-1,0 | 2 | 10/12 | 6660 | 4280 | ||||

| 3 | 6690 | |||||||

| 4 | 10/10 | 6385 | 4120 | |||||

| 5 | 14/14 | 2135 | 2130 | 6755 | 5390 | |||

| 6 | 12/14 | 4930 | ||||||

| VEE-1-1-16-1,6 | 2 | 14/16 | 2140 | 6770 | 5620 | |||

| 3 | 14/18 | 6765 | 5790 | |||||

| 4 | 12/14 | 2135 | 6755 | 4980 | ||||

| 5 | 18/22 | 2140 | 2135 | 6770 | 7030 | |||

| 6 | 16/18 | 6765 | 6220 | |||||

| VEE-1-1-25-0,6 | 2 | 10/10 | 2210 | 42 | 2540 | 2520 | 6755 | 5090 |

| 3 | 6460 | 5080 | ||||||

| 4 | 5060 | |||||||

| 5 | 12/12 | 6465 | 5850 | |||||

| 6 | 10/12 | 5310 | ||||||

| VEE-1-1-25-1,0 | 2 | 12/14 | 6780 | 6180 | ||||

| 3 | 6810 | |||||||

| 4 | 10/12 | 6805 | 5370 | |||||

| 5 | 16/18 | 2545 | 2525 | 6825 | 7730 | |||

| 6 | 14/16 | 2540 | 6820 | 6920 | ||||

| VEE-1-1-25-1,6 | 2 | 16/20 | 2555 | 2555 | 6800 | 8060 | ||

| 3 | 6830 | 8040 | ||||||

| 4 | 14/16 | 2550 | 2520 | 6820 | 6990 | |||

| 5 | 22/24 | 2560 | 2530 | 7255 | 11110 | |||

| 6 | 18/22 | 2555 | 7210 | 9750 |

The summary table of technical characteristics of bulk capacity vessels can be found here.

How to order a vertical apparatus VEE at the Saratov Reservoir Plant?

If you want to buy a vertical vessel VEE, You can:

- call at 8-800-555-9480

- download the Questionnaire, fill it out and send it at the e-mail

- use the "Request for quotation" form, provide contact information, and our specialist will contact you to clarify the request

Our specialists carry out complex services:

- oil and gas facilities supply with equipment of its own production

- engineering surveys at sites

- design of oil industry facilities

- installation of the supplied tanks and vessels

See also: