Horizontal apparatus with elliptical heads and tube bundle (GEE)

Description

The horizontal apparatus GEE with a tube bundle are designed for aboveground storage of oil products and gaseous fluids at a pressure of 0.6 MPa. At the same time, the density of the stored liquid or gas should not exceed 2000 kg/m3.

The Saratov Reservoir Plant manufactures apparatus GEE with a tube bundle of different steel grade and different volume, depending on the operating conditions and at the Customer's request.

Seismicity of the worksite should not exceed 7 points.

The ambient temperature is within the temperature range from -60°C to + 300°C. The choice of steel grade depends on the operating temperature.

Manufacture and construction of horizontal vessels with elliptical heads and tube bundle

Apparatus GEE with tube bundle are a horizontal all-welded housing with elliptical heads and a tube bundle installed inside the heat exchanger, which is designed to heat or cool the stored liquid in production needs. Heating or cooling of the internal space can be permanent or periodic.

There are fittings for the equipment installation and a hatch for inspection and repair of the internal surface, as well as for the execution of technological operations (loading-unloading, maintenance, etc.).

To access the top hatch, a ladder and an observation platform with or without a hedge can be provided.

Our plant produces GEE vessels with a tube bundle of 6.3 m3, 10 m3, 16 m3, 25 m3, 40 m3, 50 m3 and 63 m3. The diameter of shells is from 1.6 m to 2.8 m.

While designing and manufacturing, corrections can be made to the series design, for example, improvement of the design itself, changes in parts, assembly units, etc.

The Saratov Reservoir Plant has the necessary Certificates of Conformity for the production of Vessels for various purposes.

Installation of horizontal apparatus with elliptical heads and tube bundle

When installing, no direct contact between the shell and the ground surface is allowed.

This type of vessels is mounted aboveground only on different types of metal supports (leg supports, saddle supports or lug supports), depending on the operational requirements and at the Customer's request.

Command terms for order

GEE 1 - 2 - 5 - 0,6 - 2 - horizontal all-welded apparatus with a tube bundle of 5 m3, pressure 0.6 MPa, material design 2

Steel grade used for GEE vessels manufacturing

| Number of material design | Steel grade | Shell temperature, ºC | |

|---|---|---|---|

| min | max | ||

| 1 | Vsp3sp5 GOST 380-88 | -20 | 300 |

| 2 | 09G2SС GOST 5520-79 | -60 | |

| 16GS GOST 5520-79 | -40 | ||

| 3 | 12х18Н10Т (stainless steel), 10х17Н13М2Т и 10x17Н13МЗТ GOST 5632-72 | -70 | |

| -40 | |||

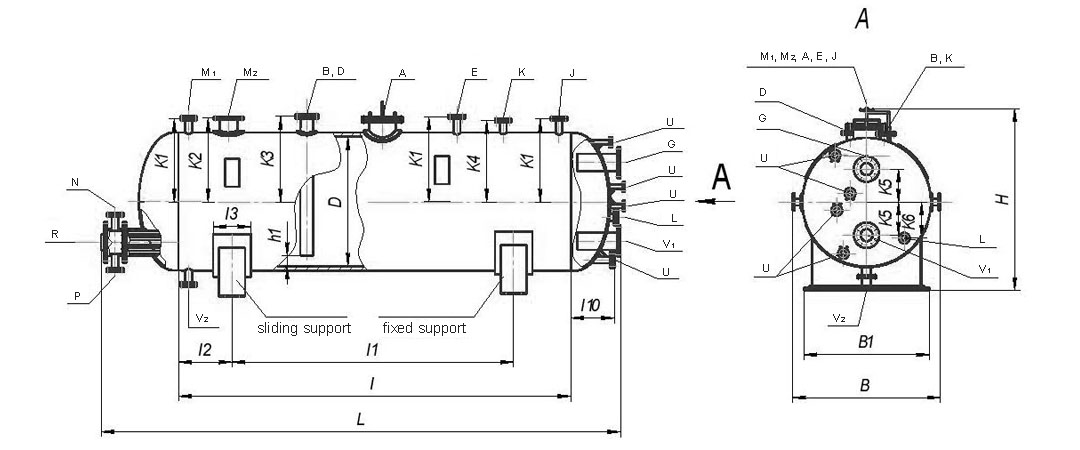

Drawing of horizontal vessel with elliptical heads and tube bundle

Characteristics of fittings

| Designation | Assignment | Counterpart | Conditions of usage |

|---|---|---|---|

| А | hatch | - | permanent for all types of apparatus, except split vessels |

| B | product inlet | flange | permanent |

| V | product outlet | ||

| G | overtop | at the Customer's request (are specified in the Questionnaire) | |

| D | calm down pipe | ||

| E | for safety valve | blank flange | |

| J | for pressure gauge | ||

| U | for the column of tubular level gauge | flange | |

| K | for displacer | blank flange | |

| L | for the thermometer | ||

| M | reserve | ||

| N | coolant inlet | flange | permanent for apparatus with heat exchanger |

| P | coolant outlet | ||

| R | for the tube bundle | - | permanent for apparatus with a tube bundle |

Nominal inside diameter of fittings

| Volume, m3 | А | B | V1 | V2 | G | D | E | J | U | K | L | M, M1 | M2 | N1, 2 | P | R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6.3 | 500 | 80 | 150 | 50 | 150 | 80 | 50 | 50 | 20 | 50 | 50 | 50 | 150 | 50 | 50 | 400 |

| 10 | 100 | 100 | ||||||||||||||

| 16 | ||||||||||||||||

| 25 | 150 | 250 | 250 | 150 | 100 | |||||||||||

| 40 | ||||||||||||||||

| 50 | 200 | 300 | 100 | 300 | 200 | |||||||||||

| 63 |

Main overall size of vessels GEE with tube bundle

| Nominal volume, m3 | 6.3 | 10 | 16 | 25 | 40 | 50 | 63 |

| Operating volume, m3, not more | 5.4 | 9.1 | 13.7 | 0.9 | 34.3 | 42 | 52.4 |

| Heat exchange surface area, m2 | 10.5 | 17.1 | 18.6 | 31.4 | 35.2 | ||

| D | 1600 | 2000 | 2400 | 2800 | |||

| I | 2500 | 4200 | 4500 | 8000 | 7000 | 9000 | |

| I1 | 1600 | 3200 | 3500 | 7000 | 5800 | 7800 | |

| I2 | 450 | 500 | 600 | ||||

| I3 | 400 | 450 | |||||

| I10 | 460 | 525 | 605 | 660 | |||

| k1 | 945 | 1145 | 1345 | 1545 | |||

| k2 | 970 | 1170 | 1370 | 1570 | |||

| k3 | 900 | 1100 | 1340 | 1560 | |||

| k4 | 885 | 1085 | 1290 | 1500 | |||

| k5 | 560 | 720 | 825 | 960 | |||

| k6 | 460 | 655 | 840 | 1015 | |||

| В1 | 1440 | 1790 | 2140 | 2480 | |||

| h1 | 100 | 140 | 160 | ||||

| Designation | GEE 1-2-6,3 | GEE 1-2-10 | GEE 1-2-16 | GEE 1-2-25 | GEE 1-2-40 | GEE 1-2-50 | GEE 1-2-63 |

Main specifications of a GEE apparatus with elliptical heads and tube bundle

| Designation | Material design | Dimensions, mm | Density of operational product, kg/m3, max | Temperature, °С, max | ||

|---|---|---|---|---|---|---|

| L | B | H | ||||

| GEE 1-2-6.3-0,6 | 1 | 4075 | 1770 | 2370 | 2000 | 300 |

| 2 | 4070 | |||||

| 3 | ||||||

| GEE 1-2-10-0,6 | 1 | 4210 | 2170 | 2770 | ||

| 2 | 4200 | |||||

| 3 | ||||||

| GEE 1-2-16-0,6 | 1 | 5910 | 2180 | |||

| 2 | 5905 | |||||

| 3 | ||||||

| GEE 1-2-25-0,6 | 1 | 6435 | 2585 | 3170 | ||

| 2 | 6440 | |||||

| 3 | ||||||

| GEE 1-2-40-0,6 | 1 | 9935 | ||||

| 2 | 9940 | |||||

| 3 | ||||||

| GEE 1-2-50-0,6 | 1 | 9115 | 3010 | 3580 | ||

| 2 | 9110 | 3005 | ||||

| 3 | ||||||

| GEE 1-2-63-0,6 | 1 | 11115 | 3010 | 3580 | ||

| 2 | 11110 | 3005 | ||||

| 3 | ||||||

The summary table of technical characteristics of bulk capacity vessels of various types can be found here.

How to order the manufacture of a horizontal apparatus GEE with a tube bundle at the Saratov Reservoir Plant?

If you are interested in the cost of manufacturing, you can:

- call at +7(8452)250-288

- download the Questionnaire, fill it out and send it at the e-mail

- use the "Request for quotation" form, provide contact information, and our specialist will contact you to clarify the request

Our specialists carry out complex services:

- supply of oil and gas industries with equipment of its own production

- engineering surveys at sites

- design of oil industry facilities

- installation of the supplied equipment

See also: