Nozzles, nipples, connecting pipes, fittings

Description

The nozzles are a ancillary equipment of vertical and horizontal tanks. The Saratov Reservoir Tank produces ancillary equipment with diameter from 50 mm to 1000 mm for various purposes. Depending on the functionality we supply:

- mount nozzle PM

- inlet - distribution nozzle PPR

- stripping nozzle PZ

- vent branch pipe PV

- gauging hatch nipple PZL

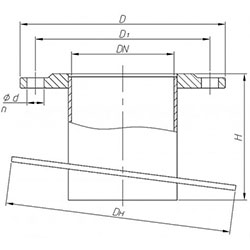

Mount nozzle PM

Mount nozzles PM serve for the installation of main equipment on vertical tanks, for example, valves, flame-arresters, etc. Depending on the tank capacity and diameter of the installed equipment we supply nozzles PM with a diameter of 50 to 500 mm. The nozzles are manufactured of steel grades, most suitable for a particular working fluid.

They can be operated in temperate conditions N and cold weather NF, placement category 1.

Technical specifications of Mount nozzles PM

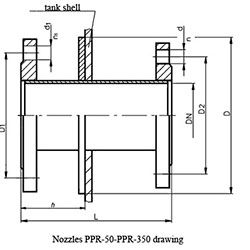

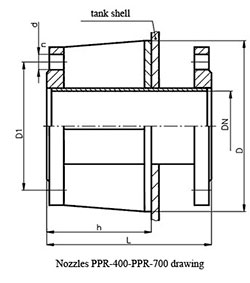

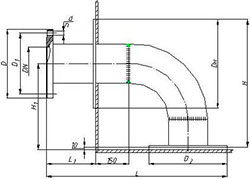

Inlet - distribution nozzle PPR

These nozzles with a diameter of 50 to 700 mm are used in the process of loading-unloading operations: they serve to connect petroleum products supply and outline pipelines. The pipe is connected to the outer flange, the rising pipe and the tank clap valves are connected to the inner flange. The design includes a reinforcing plate for stiffening. They are mounted in the first ring of vertical tanks.

The PPR nozzles produced in the climatic categories N and NF, placement category 1 for temperate and cold conditions.

Technical specifications of Inlet - distribution nozzles PPR

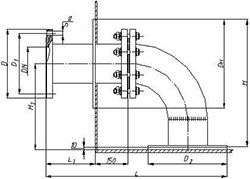

Stripping nozzle PZ

The stripping nozzles PZ are mounted in the first ring of vertical tanks for tank cleanout from bottom settlings and bottom sediments. At the Customer's request we supply two types of leadaway pipe fastenings - welded (PZ) and flange (PZ1), the pipe nominal size from 50 mm to 300 mm. Nozzles PZ are supplied with a mount nozzle.

They can be operated in tropical, temperate and cold climates, which corresponds to the climatic categories of T, N, NF placement category 1.

Technical specifications of Stripping nozzles PZ

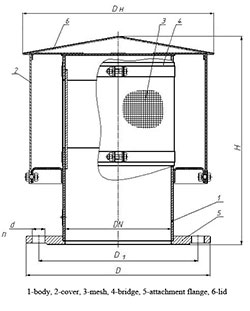

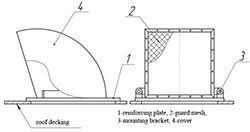

Vent branch pipe PV

Vent branch pipes PV are installed on the roof of vertical tanks for enclosure venting and vacuum formation prevention. They also prevent foreign particle from entering the oil level by copper or stainless mesh fastening at the bottom. Usually they are used with low-evaporate products or with tanks with pontoon. Depending on the operating conditions the vent branch pipes PV are used at operating pressure up to 0.25 MPa. We supply vent branch pipes PV with a diameter of 100-1000 mm and a throughout capacity of 450-3500 m3/h. The are installed on the mount nozzle PM using flange or bolt connection.

For space venting above pontoon we offer peripheral vent pipes PVR-P with a capacity of up to 4500 m3/h and diameter (comparable to a circular section) up to 500 mm. They prevent the fire dangerous gas mixtures formation above pontoon by providing natural ventilation.

The vent pipes are manufactured in climatic categories NF and placement category 1 (for temperate and cold climates).

Technical specifications of vent pipes PV

Technical specifications of peripheral vent pipes PVR-P

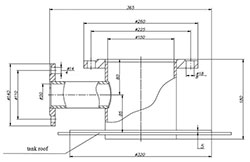

Gauging hatch nipple PZL

The gauging hatch nipples PZL serve to install gauging hatch with a nominal bore of 80 or 150 mm and vent pipe 50 mm. At the Customer's request they can be supplied with vertical or horizontal tanks.

Nipples PZL are designed for use in temperate and cold climates, placement category 1 ( climatic categories N and NF).

How to buy the Nozzles, connecting pipes, nipples, fitting for the tank?

In order to select the required size and number of nozzles, You can:

- call at +7(8452)250-288

- e - mail at with operational equipment requirement: application, operating conditions (tank capacity, properties of stored liquid), nominal inside diameter

- use the form "Request for quotation", provide contact information, and our specialist will call you back

See also:

| Breather valves | Samplers | Tank hatches |

| Bottom cleanout boxes | Nozzles, nipples, connecting pipes, fittings | Flame arresters |

| Tank clap valves |