Flame arresters

Description

Flame arrestors and flame filters are used as fire-fighting equipment on vertical tanks for storage of explosive petroleum products.

This equipment is the first stage of fire safety, which helps to protect the tanks and stored product from explosion and fire. The main purpose of flame arrestors and flame filters is to prevent sparks or flames from entering the gas space of the tank and reduce fire hazard.

Principle of action of flame arrestors and filters

Their work is based on heat absorption from a spark or flame: the cassettes of different materials included in the design bring down the temperature below the fire point of oil products. This does not arrest the operating product through the cassette.

Fire-stop assemblies (cassettes, tapes) can be made of foil, copper or aluminum alloys.

Flame arrestors and filters mounting

They are mounted on the roof of the vertical tanks under the breathing or safety valve and bolted to the counter flanges through the tightening. To protect the pipelines under pressure up to 1.6 MPa, they are installed at the site of a possible steam-and-gas mixture outlet.

Types of flame arrestors and flame filters

- flame arrestor OP-AA

- flame arrestor OP-AAN

- flame arrestor PP

- flame liquid filter POZH

- flame communication filter POK

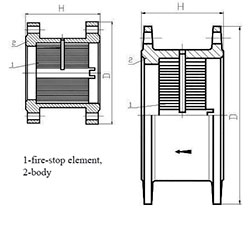

Flame arrestors OP

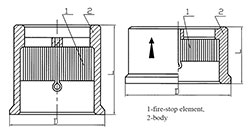

Flame arrestors OP-AA and OP-AAN protect the gas space of the tank against flame penetration. The fire-stop element, located in the body, consists of corrugated and flat ribbons, which restrain heat from the fire and extinguish it. They are manufactured of aluminium. The OP-AAN flame arrestor is split, which allows cassette inspection and its replacement if necessary.

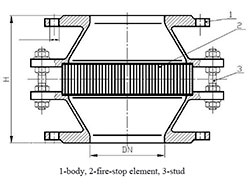

Flame arrestors PP

Flame arrestor PP is temporary device, which prevents the flame penetration to the gas space of the tank. It is attached by flanges to the mount nozzle; there is a tightening between the flange and the body that ensures interface integrity.

The fire-stop element is made of flat or corrugated ribbon and can be manufactured of aluminum or stainless steel. The specified life of flame arresters PP of aluminum alloys is 5 years, of stainless steel - 10 years.

| Flame arrestor PP | Criteria | PP-50 АА | PP-100 АА | PP-500 АА |

|---|---|---|---|---|

|

Diameter nominal DN, mm | 50 | 100 | 500 |

| Throughout capacity, m3/h | 25 | 100 | 2200 | |

| Length (D), mm | 92 | 148 | 910 | |

| Height (L), mm | 80 | 423 | ||

| Weight, kg | 1.3 | 1.5 | 93 | |

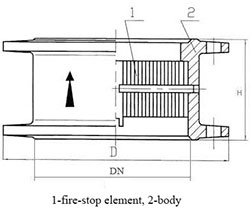

Flame liquid filters POZH

Flame liquid filters are used to prevent possible ignition of the tank for diesel fuel or gasoline storage, which can occur at the gas or steam outlet. They can be placed in cast-iron or aluminum housing. The fire-stop element is made of aluminum strips that accumulate the heat of the flame and extinguish it.

They are installation on the receiver pipe.

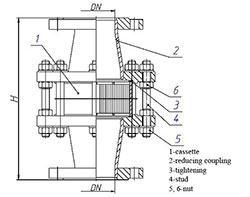

Flame communication filters POK

Flame communication filters are installed on crude oil line to prevent the flame from moving through it. The maximum pressure in the pipeline is up to 1.6 MPa.

Their design is more reinforced, as the movement of the operating product occurs at high speed and at high pressure. Having a minimum hydraulic resistance, the liquid passes freely.

The fire-stop element has high heat resistance and fire resistance. When the flame passes through the flame-extinguishing element, the temperature drops below the flash-point of the inflammable liquid. Due to this, there is a flame extinction.

Flame communication filters POK are manufactured in climatic categories N and NF and placement category 1.

How to purchase flame arrestors and filters at the Saratov Reservoir Plant?

In order to buy a flame arrestor and filter, You can:

- call the Plant at +7(8452)250-288

- e - mail at with operational equipment requirement

- use the form "Request for quotation"

See also:

| Breather valves | Samplers | Tank hatches |

| Bottom cleanout boxes | Nozzles, nipples, connecting pipes, fittings | Flame arresters |

| Tank clap valves |