Vessels with elliptical bottom, split elliptical head, agitator and welded jacket

Description

Apparatus with elliptical bottom, split elliptical head, agitator and welded jacket are intended for use in petrochemical, oil and gas and other industries for mixing of two or more liquid and gaseous media (mixtures, suspensions, emulsions). The structural design itself and the agitators determine the basic requirements for working media:

- density - up to 2000 kg / m3

- dynamic viscosity - up to 200 Pa x s

- volume concentration of solids - up to 30%

- temperature - from -40ºC to +350ºC

They can be operated with various liquids: neutral/aggressive/toxic, explosive and flammable. The choice of material for the manufacture and the type of mixer depends on the class of liquid and its characteristics.

Apparatus with split elliptical head, stirrer and jacket are operated at a pressure of up to 6.3 MPa. And in case of application for filling or at vacuum, the residual pressure shall be not less than 665 Pa.

Manufacture of vessels with split elliptical head, mixing device and welded jacket

To manufacture split vessels with agitator and jacket the engineers select steel grade, structural design, and offer the optimal fittings for the equipment layout.

So, depending on the operating conditions (temperature, liquid properties) we use steel grades St3sp (carbon steel) and 12H18N10T (stainless titaniferous austenitic steel).

To protect the inner and outer surface from the negative environmental effects, on the one hand, and the influence of the operating media, on the other, the body undergoes anticorrosive treatment and is coated with primer, paint, enamel.

The quality of the supplied vessels is confirmed by the leakage test, electric resistance, temperature and vibration. Together with the vessel the Customer receives:

- set of equipment (according to Customer's requirement)

- Product certificate

The design of the vessels with elliptic bottom and split head, stirrer and jacket

The body is split, that is, the head is removable and fastened with flange connections. This is done for flexibility in application: it can be removed to service and clean the inner surface.

The apparatus are installed in a vertical orientation on the supports. The operating medium is filled through the head, the output - through the bottom.

The agitator is installed through the head on the pillar. Our experts offer various types of mechanical mixing devices: blade mixers (three-blade, six-blade), gear, turbine, frame, spiral, ribbon (with scrapers). To save interface seal mechanical and stuffing box seal or velocity seal are used (in accordance with GOST 20680-2012). The choice of the type of seal depends on the medium characteristics and the pressure.

For constant or variable heating or cooling of the medium, a smooth jacket is welded from the outside, which appears as a welded plate, the space between which and the shell is filled with a coolant - water, steam, condensate or organic coolant. The pressure in the jacket is designed based on the choice of heat-transfer medium.

The housing is provided with fittings through which the product is filled, drained, for process equipment installation (valves, pressure gauges, thermometers, etc.), a hatch that serves to access to the inside of the vessel.

As an example below you can see the layout of the fittings and their purpose.

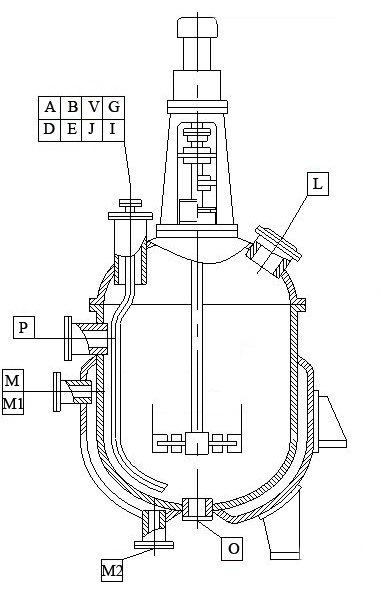

The drawing of the vessel with elliptic bottom and split head, stirrer and jacket*

*the design of the necessary fittings, their layout, as well as the selection of additional equipment is carried out individually on the basis of a Questionnaire or technical design specification

Nozzle schedule

| Designation | Application |

|---|---|

| A | product inlet |

| B | reserve |

| V | reserve |

| G | for pressure safety valve |

| D | calm down pipe |

| E | reserve |

| J | for pressure meter |

| I | for temperature meter |

| L | hatch |

| M, M1 | heat-transfer medium inlet |

| M2 | heat-transfer medium outlet |

| P | for overflow |

| О | product discharge |

How to buy split vessel with an elliptical head, an agitator and welded jacket at the Saratov Reservoir Plant?

To order its manufacture, You can:

- call at +7(8452)250-288

- send an e-mail at with the filled-in Questionnaire

- use the form "Request for quotation"

- e-mail at with the identity code of the vessel required

Specialists of the Plant perform complex services:

- oil and gas facilities supply with equipment of own production

- engineer surveys at the facilities

- oil industry facilities design

- installation of supplied equipment

See also: