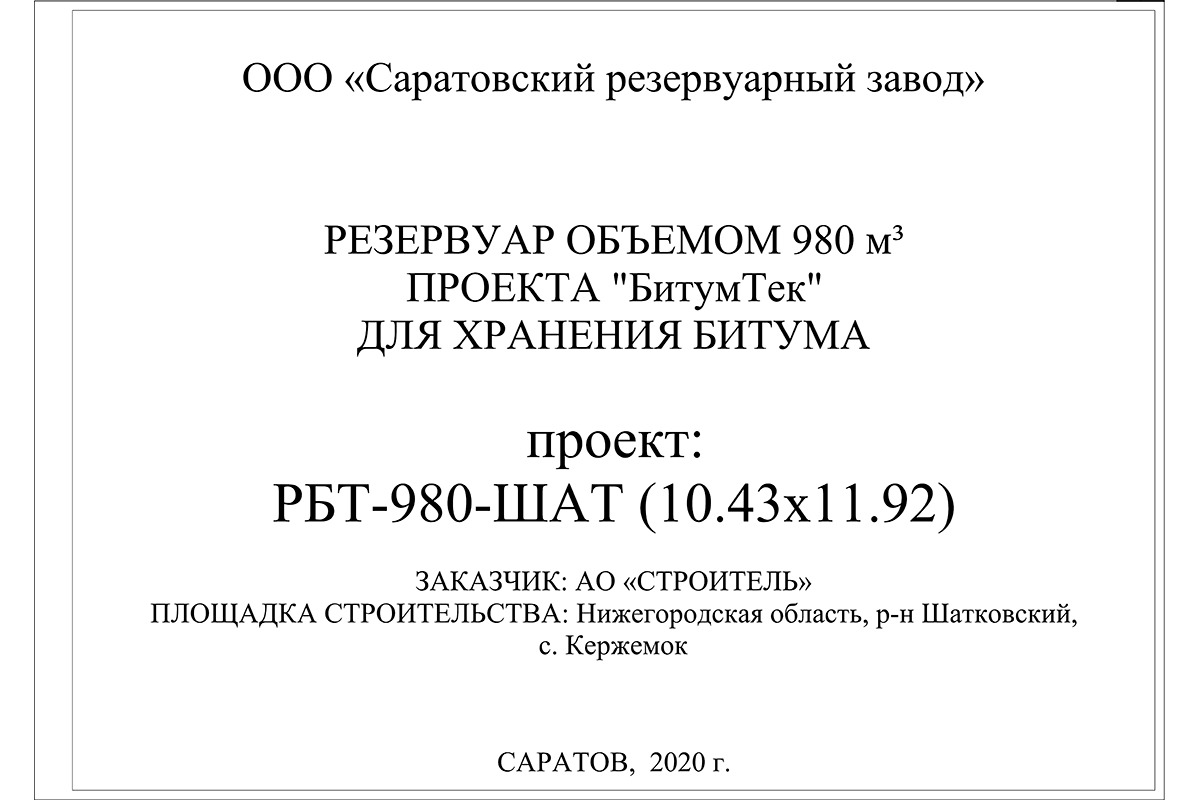

Vertical tank for bitumen in the Nizhni Novgorod Region

Customer: AO «Stroitel»

Location: industrial community Shatki, the Nizhni Novgorod Region

Company sector:

Construction and repair of buildings and housing; construction, repair and maintenance of highways.

Date of works held:

December 2020 - February 2021

Project:

Erection of the tank 980 m3 for bitumen storage for the asphalt concrete plant

The Saratov Reservoir Plant has completed a project work package on the supply of a vertical bitumen tank (RBT) with a capacity of 980 m3. Due to the urgent need of the Customer, the tank was designed, fabricated and erected within 3 months.

The tank design differs from the typical design of vertical tanks for petroleum products storage. The RBT type tank has an increased effective volume which is 978 m3. The physicochemical properties of the processing medium (bitumen) required the installation of a piped heating system (coils) with a total area of heating of 73 m2, as well as outer thermal insulation, which provide heating and maintenance of the operating temperature of bitumen up to +110°C.

At the request of the Customer, the structural steel of the tank is made of commercial-quality constructional carbon steel St3sp5-sv. Pipes and flanges of coils are made of non alloyed steel St20.

Main specifications:

- Stored product - bitumen;

- Tank amount - 1 pcs with a capacity of 980 m3;

- Material of the tank - St3sp5-sv; material of the heater - St20;

- Erection procedure - Roll method;

- Heaer - 3 coils made of seamles pipes; heat-transfer liquid - hot oil (up to +240ºC);

- Heat insulator - mineral wool board 1000 mm*500 mm*100 mm with the density 50 kg/m3.

Specific features and complexities of the project

The design, manufacture and erection of the bitumen tank was carried out in a short time frame - within three months - in order to prepare the Customer's facility for the season of increased demand for asphalt concrete products.

Construction and assembly work became more complicated due to the ongoing operating procedure at the facility during the entire duration of the tank erection, as well as tight working space at the enterprise.

Due to the strict requirement for the timing the hydro-testing of the tank and heater were carried out under freezing temperature, which required additional heating of the water.

The Engineering department together with the production and a structural unit of the Saratov Reservoir Plant performed the following works:

- design documentation development for the tank: KM project (metalwork), heat insulator project (TI), heater project (TN);

- fabrication of primary steel member and secondary steel of a vertical tank made of carbon steel (shell, fixed conical roof, rollable bottom plates, stair tower, hatches and pipes in the shell and roof) and a pipe coil made of steel grade St20;

- vertical tank delivery by road;

- construction and assembly work (unrolling of bottoms and shell, roof installation, welding of hatches and pipes, installation of seamless heater pipes, hydraulic testing, heat insulator fixing). The heat insulator is made of mineral wool boards with a thickness of 100 mm for the shell and roof of the tank. A galvanized sheet 0.8 mm thick was used as the cover layer of the roof, and a profiled sheet 0.7 mm thick was used of the shell.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design