Expansion of bitumen storing facility in Cherepovets

Customer: OOO «ABZ DorStroj»

Location: Cherepovets, the Vologda Region

Company sector:

Production of asphaltconcrete and bitumen-concrete mixes for road construction.

Date of works held:

July 2021 - November 2021

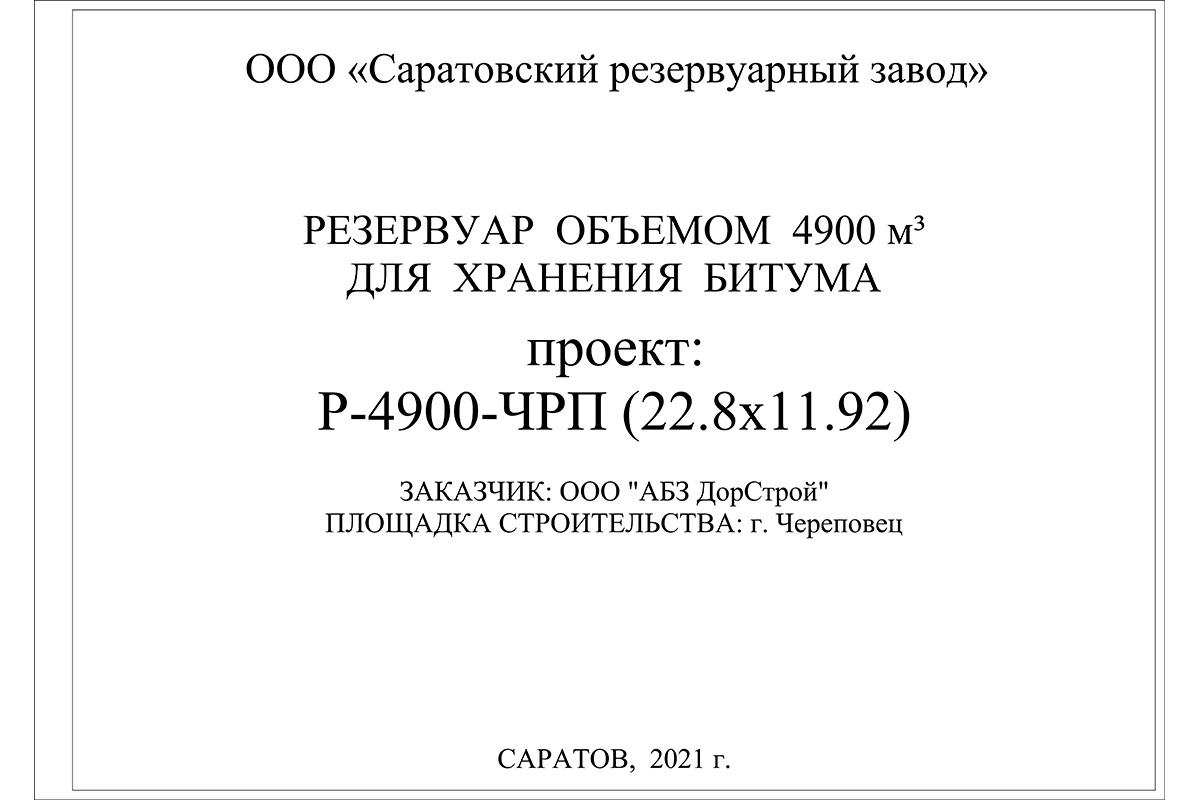

Project:

Expansion of bitumen storing facility in Cherepovets. Erection of the vertical tank for bitumen storage with a capacity of 4900 m3

In order to increase bitumen production for the Customer in Cherepovets, the Saratov Reservoir Plant completed work on the packaged supply of a vertical bitumen tank with a capacity of 4900 m3.

The tank is characterized by an increased useful capacity and is equipped with a specially designed piped coil, which heats bitumen during storage, as well as at the discharge point of the operating product due to its high viscosity.

Also, heat insulator is provided in order to maintain the operating temperature. It is made of a non-flammable hydrophobizated plate based on ISOROC mineral wool plates with a size of 1000 * 5000 mm and a density of 50 kg / m3. The cover material (profiled sheets on the shell and galvanized sheets on the roof) has a thickness of 0.7 mm.

Main specifications:

- Stored product - bitumen;

- Tank amount - 1 pcs with a capacity of 4900 m3;

- Material - 09G2S;

- Erection procedure - Roll method;

- Overall dimension - diameter 22800 mm, shell height 11920 mm;

- Additionally: a heater with hot oil, heat insulator made of mineral wool boards with a thickness of 100 mm.

Specific features and complexities of the project

The main feature of the project was the design of a custom heater.

The operating temperature of bitumen (up to +130°C) will be maintained due to the circulation of a heat-transfer medium, namely, a hot oil under pressure of 0.6 MPa, heated up to +180°C. The heat exchange surface area is 238 m2.

The main coil is made of two unit seamless pipes with dimensions of 108*6 mm made of St20 steel.

The small coil (a heating up coil) is located on the outlet pipe and is made of pipes 57*5 mm in size.

Work on the supply of the vertical tank RVS-4900 on a turnkey basis included:

- development of a package of design and detailed documentation: KM project (for metalwork), TN project for heater, TI project for heat insulator;

- production of primary steel members and secondary steel of vertical tank, as well as process equipment: two rollable plates of bottoms with annular plates, two panels of shell, a conical roof, heaters (main and small), hatches and pipes, in the wall and roof, a hoop ladder, a caged service platform;

- delivery of the rollable plates, roof and other steel work by road;

- construction and assembly work: unrolling of the bottom plates, erection of rolled plates of shell, assembly of a fixed roof,tie-in of proccess hatches and pipes, assembly of an internal tank heating system, hydro-testing.

Сompleted work

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design