Transportable fuel filling station construction project in the Kemerovo Region

Customer: JSC "SUEK-KUZBASS"

Location: Leninsk-Kuznetski, the Kemerovo Region

Company sector:

The biggest coal-fuelled energy enterprise on power-generating coal supply. The major power producer in Siberia.

Date of works held:

September 2019 - September 2020

Project:

The extension of the container filling station fleet for the quarry machinery

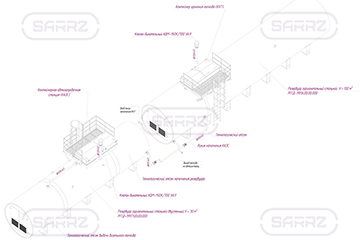

In order to increase the number of refueled equipment Saratov Reservoir Plant carried out a project work package on the supply of a fuel filling station as part of the container filling station with a double-walled tank and a container for diesel fuel storage, which are combined into a single mobile complex that allows to fuel up at a speed of up to 800 liters per minute.

The container filling station is made in the form of a single unit (monoblock), inside which there is a tank for fuel storage and issue, as well as two engineering compartments. There is a fuel-dispensing unit with the necessary fittings in the first, and a fuel pump assembly with a set of operational and emergency equipment in the second one. The container is coated with a steel sheet.

The fuel storage container is also made in the form of a single unit with a tank and a engineering compartment with a pump and safety stop valving inside.

The fuel filling station is highly automated due to the use of transportable fuel filling station controllers, which are introduced into the automatic operations-control system "OpenMine".

Fire protection of the station is performed by a warning system and powder-type extinguishers. Shut-off and emergency valves prevent the occurrence of fire hazardous situations at the station.

Main specifications:

- Supply package: container filling station, container for diesel fuel storage;

- Сontainer filling station: double-wall horizontal tank with a capacity of 50 m3, an engineering compartment for diesel fuel dispensing and tank filling;

- Сontainer for diesel fuel storage: a single-wall horizontal tank with a capacity of 100 m3, an engineering compartment for tank filling line, fuel issue line, diesel fuel dispensing pipeline;

- Diesel fuel output rate: not less than 800 liters per minute;

- Supplementary equipment: fuel-dispensing unit, self-priming and centrifugal pumps, tank filling assembly, liquid filters, instruments, valves and fittings.

Specific features and complexities of the project

The discharge capacity of the filling station, a high degree of explosive and fire safety and process automation, compact design are the main advantages of the project.

The Customer needed a transportable fuel filling station, which was effectively implemented in the form of a two-unit structures, inside which there were diesel fuel tanks, engineering compartments with pumps, an automation system, a fuel pump, a fuel-dispensing unit, control and instrumentation for commercial and technological accounting of filling operations, and shut-off valves. The units are connected by a piping only at the operation facility for ease of delivery.

Engineering department of SARRZ has implemented a project work package which contains:

- project engineering and Operations Reference Manuals development;

- manufacture of equipment at in-house production sites;

- container filling station and fuel tanks delivery by vehicular transportation;

- installation supervision;

- fuel filling station commissioning and start-up: inspecting the pumps connections and Electrical Control & Instrumentation, introducing automation system into an existing Automated Dispatch Control System, inspecting and debugging of the auxiliary systems operational performance (automatic fire alarm, gas hazard monitoring and fire-fighting system, etc.), calibration of fuel gauge unit, fuel-dispensing unit setting-up, wiring up and debugging the controller, as well as tanks gauging and performance check of the heating elements.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design