Construction of edible molasses storage facilities in Kaliningrad

Customer:

Agricultural enterprise

Location:

Svetly, the Kaliningrad Region

Company sector:

Production of prepared animal feed, oils, their fractions, fats

Date of works held:

December 2019 - April 2020

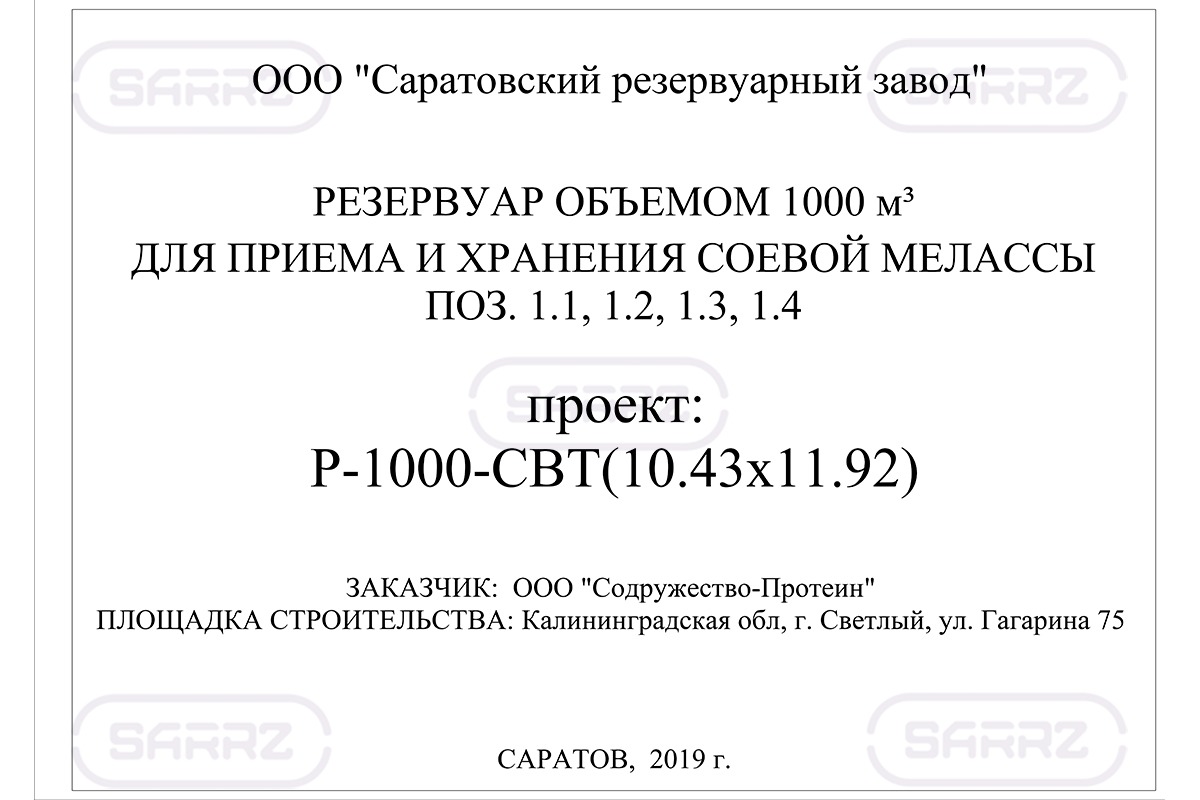

Project:

Construction of edible molasses storage facilities at «Soy protein concentrate production plant with a capacity of 510 tons per day»

Soy protein concentrate is a purified protein product for feeding of all types of animals and birds, which (the product) is obtained by the alcohol extraction and parallel removal of melt sugar. Edible molasses is a waste product during the processing of sugar beet, but, at the same time, it becomes food for farm animals.

Whereas, in fact, these two substances are food products, yet for animals, storage tanks for these substances should have an appropriate internal coating and are equipped with a temperature maintenance system.

Main specifications:

- Stored product - edible molasses;

- VST amount - 4 pcs, with a capacity of 1000 m3 each;

- Material - 09G2S-12;

- Circular ring thickness - 6-7 mm;

- Accessory: breathing combination valve of KDC type, tubular heater;

- Overall dimensions: diameter - 10430 mm, height - 11920 mm;

- Tubular heater area - 88 m2;

- Heater coil material - stainless steel 12X18H10T.

Specific features and complexities of the project

Four vertical tanks were being erected simultaneously, as they formed a single storage farm under the project.

The construction site was located on the shore of the Baltic Sea, and therefore the high humidity of the air "interfered" with the erection procedure: anti-corrosive inner coating application had to be carried out at a humidity of less than 75%.

The weight of the heaters (2 tons each) required additional lifting machines.

Tanks hydraulic tests were carried out simultaneously with the subsequent withdrawal of the involved water outside the facility.

Specialists of the Saratov Reservoir Plant carried out a complete cycle of works on the tank farm construction for the edible molasses storage on the territory of the Soy Concentrate Production Plant. So, we have performed:

- development of the KM project for the steel work of vertical tanks VST-1000, the thermal insulation project development (TI project), the heater project (TN project) and the VST anti-corrosion protection project (AKZ);

- manufacture of the four vertical tanks steel work. Each VST consisted of a rolled shell plate with dimensions of 11920x10430 mm, two bottom plates, a conical roof with an external frame;

- delivery of primary steel members and secondary steel by rail, and tank equipment (breathing valves) by road;

- erecting works included: foundation construction, unrolling of the rolled plates of the bottoms and the cylindrical shell, installation of the coils of the tubular heater, anti-corrosion treatment of steel work, painting of the internal and external surfaces of the VST-1000, hydraulic tests.

Due to the special requirements for the steel work protection, the corrosion protection system consisted of the following:

- the paint produced by HEMPEL, namely HEMPADUR 85671, was chosen as the internal coating, which was applied in three layers with a thickness of 10 microns each;

- the outer surface was coated with GF-021 base coating in one layer with a thickness of 15-20 microns and PF-115 enamel in two layers with a thickness of 40-50 microns;

- stairs, service platforms and fences were coated with GF-021 base coating in 1 layer with a thickness of 15-20 microns and "Armokot F100" paintwork material in 1 layer with a thickness of 100 microns.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design

Customer feedback

Operations director Shumilin N.K.

Dear sir Ilja Valerjevich!

By this letter, Group of Companies "Sodruzhestvo" expresses its gratitude to the team of OOO "Saratov Reservoir Plant" for the work performed on the construction of a soy molasses storage farm at the plant for the production of soy protein concentrate with a capacity of 510 tons per day (the location of the facility: 65 Gagarina str. Svetliy Kaliningrad Region 238340 RF). The following scope of work was performed:

The total tonnage of the supplied and erected metal work was about 160 tons.

The above-listed works were performed in strict accordance with the Project Schedule, in compliance with the project requirements.

Group of Companies "Sodruzhestvo" recommends OOO "Saratov Reservoir Plant" as a reliable and responsible partner in the tank erection field.