Bitumen storage tank erection at a roofing material production facility

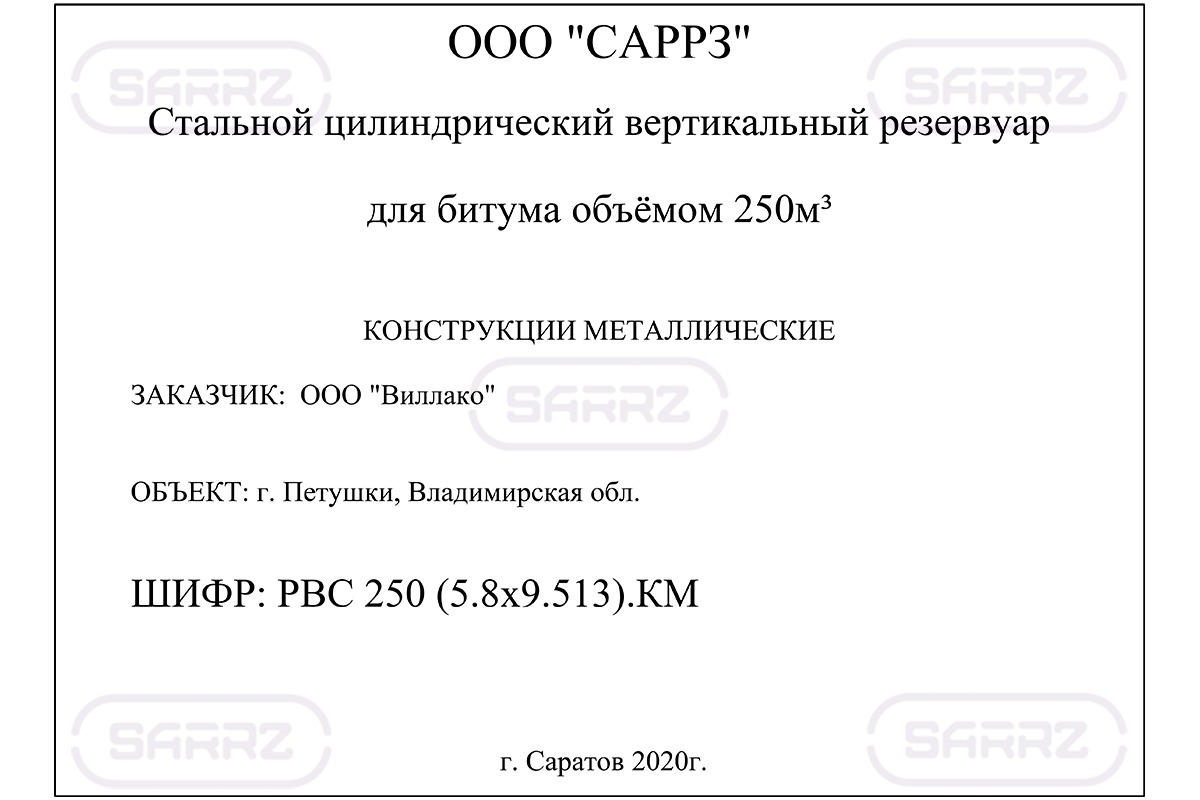

Customer: ООО "Villaco"

Location: Petushki, the Vladimir Region

Company sector:

A global leader in production of bitumen-polymer rolled roofing and waterproofing materials

Date of works held:

January 2020 - August 2020

Project:

Bitumen tank farm extension at a roofing material production facility

In order to increase of bitumen storage facility as a feedstock in the production process of roofing material production, Saratov Reservoir Plant has completed a set of services on the supply of a vertical steel tank (VST) with a volume of 250 m3 for bitumen storage at a maximum temperature of +210°C. Due to the fact that bitumen is a resinoid substance, it is necessary to maintain a certain temperature for its storage and subsequent operation, which reduces its viscous properties. Therefore, the engineering decision was proposed to equip the tank with an internal heater with a total surface area of 29 m2. Additionally, the shell and roof were heat-insulated.

Main specifications:

- Operating medium - bitumen;

- Material: 09G2S as per GOST 19281-2015;

- Metal work: plate-by-plate bottom, roll shell, cone panel roof with the slope of 1:8, stairs - step ladder;

- Shell heat insulator - synthetic binder-based mineral wool heat insulation plates; roof heat insulator - foil-coated mineral wool plates; protective coat - galvanized sheet metal;

- Inner heater: heat transfer medium - organic oil with a temperature of 300ºС.

Specific features and complexities of the project

The bitumen tank erection was carried out in the conditions of an operating enterprise and in immediate proximity to the existing tanks.

The tank's metal structures were erected using two methods: plate-by-plate method (for bottom) and the unrolling of the rolled shell.

The engineering solution provided for a tube inner heater and external heat insulator made from mineral wool plates and foil-coated mineral wool plates with an upper protective coat of galvanized profiled sheets.

When developing the project, the European standards of Basic engineering were taken into account, since the Customer is part of the European holding BMI.

In accordance with the specification and schedule of works under the contract for the packaged supply of the vertical tank VST-250 for bitumen storage at the facility in the Vladimir region, design engineers and construction and erection department of the Engineering Department of the Saratov Reservoir Plant performed a work package, including:

- development of a engineering solution for extension the bitumen tank farm;

- implementation of the KM project, thermal insulation design and heat insulator design;

- manufacture of the vertical tank VST-250 metal structures at in-house production sites;

- delivery of tank metal structures by road;

- bottom plate-by-plate erection;

- erection of the roll shell, fixing of the roof and secondary steel;

- assembly of the inner tube heater;

- paint application KO8101 in 3 layers with a thickness of 50 microns;

- heat insulator assembly (mineral wool plates and galvanized sheet metal);

- hydraulic testing of bitumen tank.

The delivery package also includes: a roof platform with a step ladder and a perimeter railing, ground clamps, a shell manhole with a low layer branch pipe, a manhole with a hatch for an agitator, a liquid level connection, a vent pipe and discharge sleeve, a vent branch pipe, a pipe for temperature transmitter installing, a heater line.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design

Customer feedback

Engineering Manager of ООО "Villacо" Palikhov S.А.

OOO "Villaco" expresses its gratitude to the specialists of OOO "Saratov Reservoir Plant" for the successful implementation of the project for the vertical tank VST-250 for bitumen storage erection.

Within the framework of this project, SARRZ has developed engineering documentation, namely, a KM project, an anti-corrosion protection design (AKZ), a heat insulator desing (TI) for the vertical steel tank VST-250; metal structures of the tank were manufactured and delivered to the construction site in Petushki, the Vladimir region, equipment installation work, anti-corrosion protection and thermal insulation were carried out as well.

All the works were completed within the time frame. The cooperation with the SARRZ specialists was productive and fruitful. We are convinced of the reliability and good workmanship of SARRZ. We will be glad to further cooperation.

We recommend this company as a professional and reliable partner.