The extension of the tank farm in Nizhnekamsk

Customer:Oil refinery

Location: Nizhnekamsk, Republic of Tatarstan

Company sector:

Oil production

Date of works held:

September 2019 - September 2020

Project:

Tank farm extension for crude hydrocarbons higher throughput at AO “Taneko” in Nizhnekamsk: chemical treatment plant

Saratov Reservoir Plant has fulfilled a large order for the design, manufacture and erection of 12 vertical tanks in total, which will be involved in the chemical treating process at hydrocarbon processing plants.

All tanks are custom-designed, taking into account the properties of the operating medium and running conditions. The delivery package of each tank also includes secondary steel and equipment: stairs and service platforms, hatches and pipes in the shells and roof. The operating temperature will be maintained due to the heat insulation used.

The designed product life of the tanks is 20 years.

Main specifications:

- The tanks size: VST-500 for the feed treated river water - 2 pcs, VST-500 for the clarified water - 2 pcs, VST-500 for permeate of reverse osmosis plant - 2 pcs, VST-200 for brine reverse osmosis gathering - 2 pcs, VST-150 with conical bottom for waste water collection and Effluents averaging - 2 pcs, VST-630 for chemically demineralized water - 2 pcs;

- Material: 09G2S-12 as per GOST 19281 (VST-500, VST-200, VST-150 with conical bottom), 12Х1810Т as per GOST 7350 (VST-630);

- TAnk importance class - КС-2b as per GOST 31385-2016;

- Optionally: outer coil from steel grade St20 (Ст20).

Specific features and complexities of the project

Construction and assembly work was carried out amid the pandemic with the implementation of all containment measures and regular inspections of Rospotrebnadzor (Russian Federal State Agency for Health and Consumer Rights).

The confined spaces at the construction site predetermined the distance between the tanks shells in 1 meter.

Based on the Customer's requirements, we developed a complex engineering solution for an outer coil for each tank, the number of joints of which reached up to 400 pcs.

During the erection procedure, on-stream introduction of changes were being made to the Detailed design documentation in accordance with the field conditions.

The SARRZ Engineering Department carried out a work package on the expansion of the tank farm and the installation of chemical treatment plant at the hydrocarbon processing facility. The scope of work included comprehensive services, namely:

- development of design and operational documents, including design for each RVS, platforms and walkways design, anticorrosive protection design and thermal insulation design;

- vertical tanks manufacture by roll method from low-alloy and stainless steel;

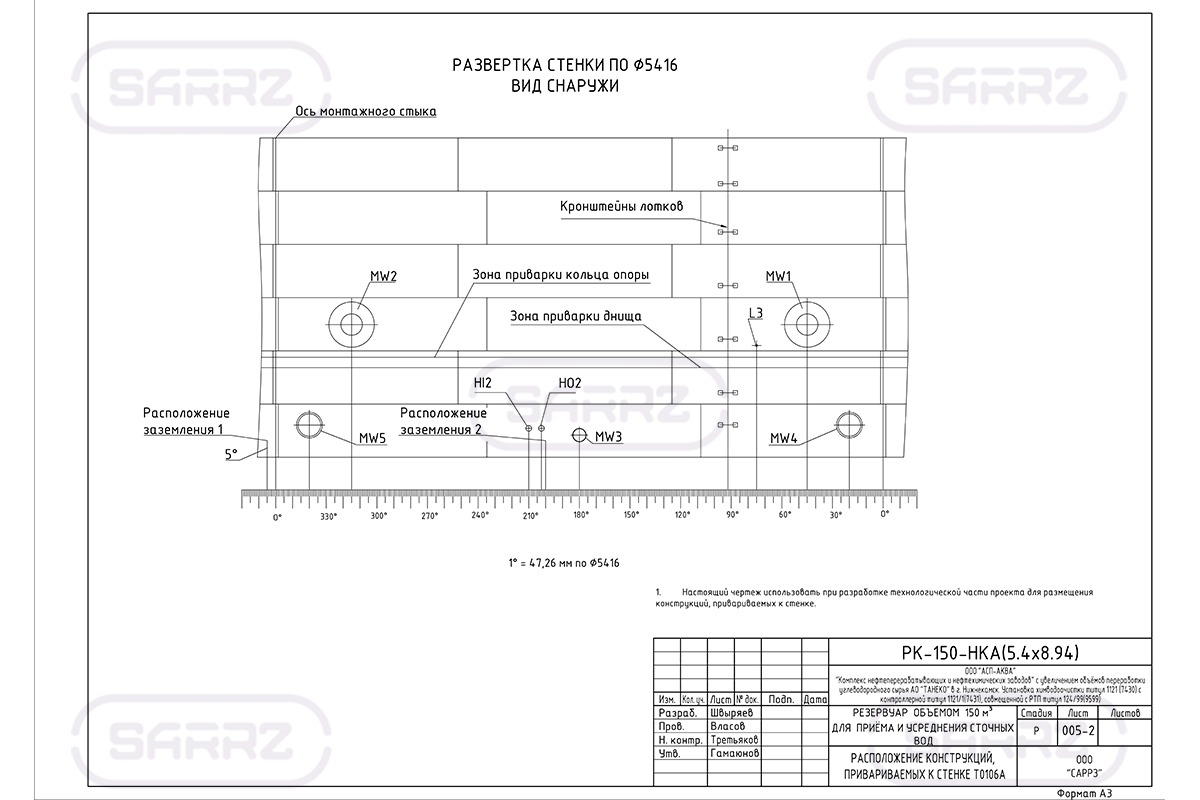

- tank's metal structures erection: unrolling of the roll shells, bottoms, roofs;

- installation of service platforms, railings, stairs;

- welding in of hatches and pipes in shells and roofs in accordance with design consideration;

- mounting of the outer coil of the heater;

- hydraulic testing of vertical tanks;

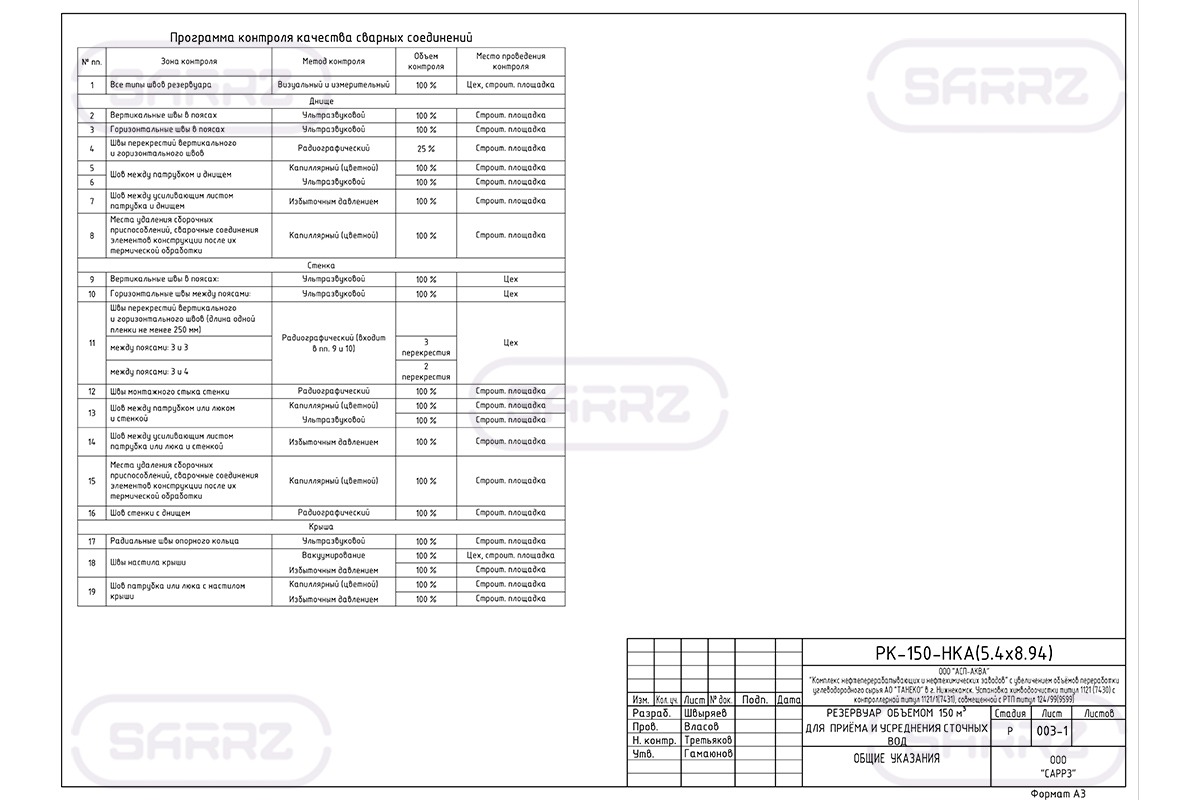

- non-destructive testing performing of installed steel work in accordance with the quality-control program of welded joints.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design