Tank farm construction in Togliatti

Customer:

Chemical factory

Location:

Togliatti, the Samara Region

Company sector:

Chemical factory. Production of nitrogen fertilizers, caprolactam and products of its processing.

Date of works held:

November 2018 - August 2020

Project:

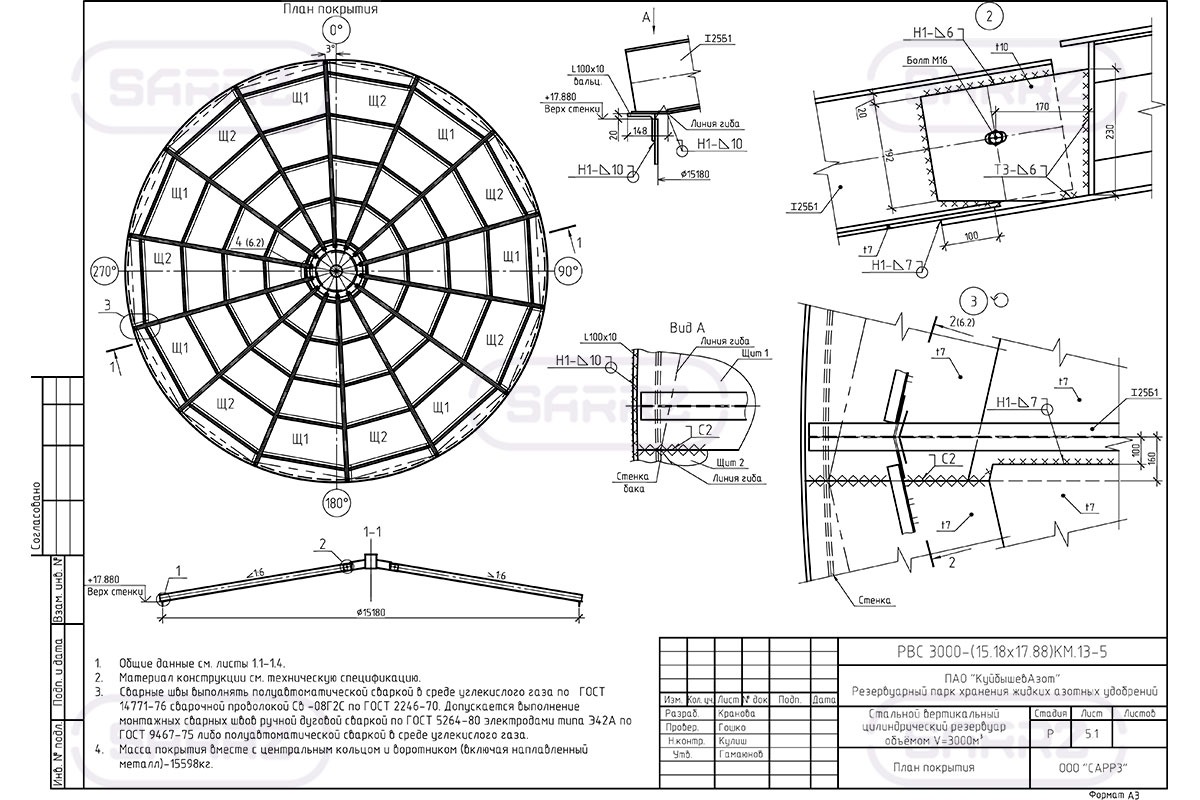

Tank farm construction for nitrogen solution storage (carbomide-ammonium mixture)

Nitrogen solutions are an aqueous solution of ammonium nitrate and urea. This mixture includes three forms of nitrogen - nitrate, ammonium and amide. A special feature of storing fertilizers of this type is the need to take into account the aggressive action of the solution on the tank structural steel, which are necessarily to be protected by acid-resistant coatings and alkali-resistant painting systems of special application.

Main specifications:

- Stored product - сarbamide-ammonia mixture (nitrogen solutions);

- VST ammount - 3 pcs, the capacity of each - 3000 m3;

- Material - 09G2S;

- The tank foundations in a sunken ditch;

- Thermal insulation with mineral wool boards with a thickness of 80 mm for shells, 100+150 mm for the roof is provided;

- The tanks are bridged in accordance with the project of passing platforms and walkways.

Specific features and complexities of the project

The main complexity of the project implementation is the tank foundations for the erected tanks, which were located in a sunken ditch (3 meters below ground level). At the same time, there was no possibility of locating construction machinery in close proximity to the ditch, which did not allow the shell to be unrolled in the conventional method. As a result, it was decided to unroll the shell with a height of 18 m with the help of manual wire rope pullers and hand-operated winches.

Another feature was the simultaneous erection of all three vertical tanks. Thus, there were up to 6 units of hoisting crane of various lifting capacities at the construction site at the same time, including a 350-ton crane, a 150-ton crane, a 70-ton crane, a 25-ton crane (with a 39-meter boom).

The vertical tanks steel work were made of 09G2S steel grade by rolling and delivered to the facility in the Samara region. The commencement of construction works was postponed at the request of the Customer due to the need to prepare the construction site and relocation of communication network.

The total period spent on carrying out the full scope of installation work is 8 months. After completion, the employees of the SARRZ Plant performed a quality monitoring of the installed structures by specialists of non-destructive testing laboratory and hydraulic tests of the VST, which were successfully passed.

To protect against corrosion, the surfaces of the tank were treated for the paintwork materials application - abrasive blasting, dedusting, degreasing were carried out. The outer side is coated with primary painting GF-021 in 1 layer and PF-115 enamel in 2 layers. Chemically resistant coating AntikorKhim was applied to the inner surface in 3 layers with a thichness of 100 microns. The coating is designed for immediate contact with acidic (up to PH - 2.5) and alkaline (up to PH - 12.5) media at temperatures up to +70°C. Service platforms, stairs, fences, railings, hatches and pipes were protected by a weather-resistant coating OS-70-01 (organosilicates) in 3 layers with a thickness of 60 microns.

The thermal insulation is made of mineral wool boards with a thickness of 80 mm for the tank shell and for the roof with a total thickness of 250 mm. As a cover layer, a galvanized profiled sheet with a thickness of 0.7 mm was used for the shell and a smooth galvanized sheet of the same thickness for the roof.

Сompleted work

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design

Customer feedback

Chief of the Supply chain management Abdalov N.N.

By this letter, we express our gratitude to OOO "Saratov Reservoir Plant" for the turnkey construction performed within the framework of the project "Tank farm construction for nitrogen solution storage". The following terms were provided in the project:

The total tonnage of manufactured and installed steel work was about 365 tons.

The above works were completed on time, in compliance with all the design requirements.

We recommend OOO "Saratov Reseroir Plant" as a reliable and responsible partner in the tank construction company sector.