VST-250 erection in Tver Region

Customer: MCM GROUP CO. LTD.

Location: Redkino settlement, Tver region

Company sector:

Manufacturer of antifreeze, glass cleaners and cooling fluids, a leading distributor of premium base oils and one of the largest suppliers of lubricants.

Date of works held:

February 2020 - February 2021

Project:

Tank erection for antifreeze, glass cleaners and cooling fluids manufacture procedure

In order to provide the raw material reserve the Saratov Reservoir Plant has completed a package of work on the supply of tank equipment according to the materials management. Currently, construction and assembly works have been completed at the facility.

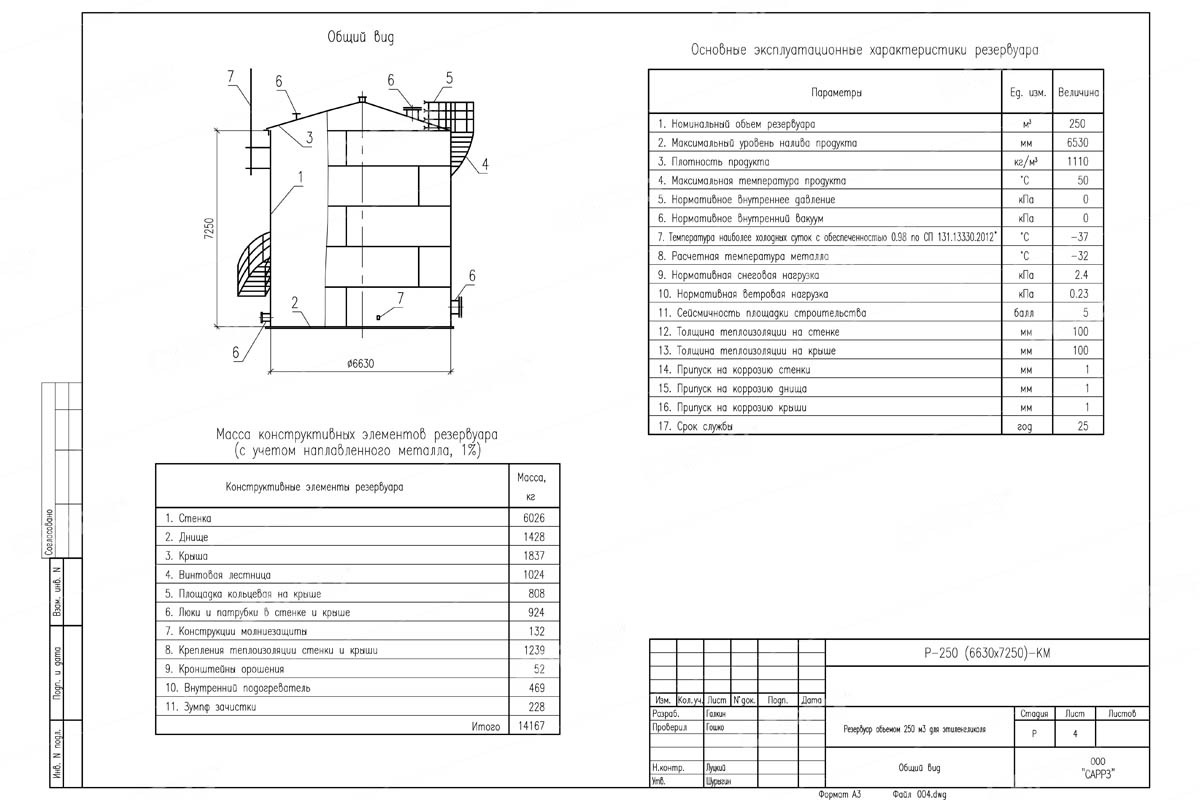

Main specifications:

- Stored product - ethylene glycol;

- VST amount - 2 pcs with a capacity of 250 m3 each;

- Material - АISI 430;

- Erection procedure - Roll method;

- Heat insulator: mineral wool boards with a thickness of 100 mm, galvanized sheet with a thickness of 0,7 mm.

Specific features and complexities of the project

The main feature of this project was the implementation of a complete set of detailed construction documentation: KM project (Basic Design), thermal insulation design (TI), process solutions design (TX).

The second feature was the anti-corrosion protection of stairs, platforms and railings with a coating of Armokot V500, RAL7047 (light gray color).

The priority for the Customer was the choice of a solid performer, experience in the market and the confidence of the company, which could confirm the compliance of its works with performance quality standards. Due to the high level of quality of the work performed, SARRZ was able to forge partnerships with the Customer and implement the project in accordance with the accepted Technical Design Assignment.

The Engineering department of the Saratov Reservoir Plant performed the following works:

- development of a KM project, a thermal insulation design (TI), a process solutions design (TC) for vertical tanks;

- production of rolled plates of vertical tanks;

- tanks metal structures truck hauling;

- erection works (metal structures erection, hydraulic tests, thermal insulation assembly). The thermal insulation of the tank shells is made of mineral wool boards with a thickness of 100 mm. A galvanized profiled sheet with a thickness of 0.7 mm was used as a coating.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design