Construction site of VST-5000 in Kemerovo

Customer: Nitrogen-fertilizer maker

Location: Kemerovo, the Kemerovo Region

Company sector:

A Nitrogen-fertilizer maker in Russia, a supplier of ammonium nitrate for industrial use to mining enterprises in Siberia and the Far East.

Date of works held: May 2020 - December 2020

Project:

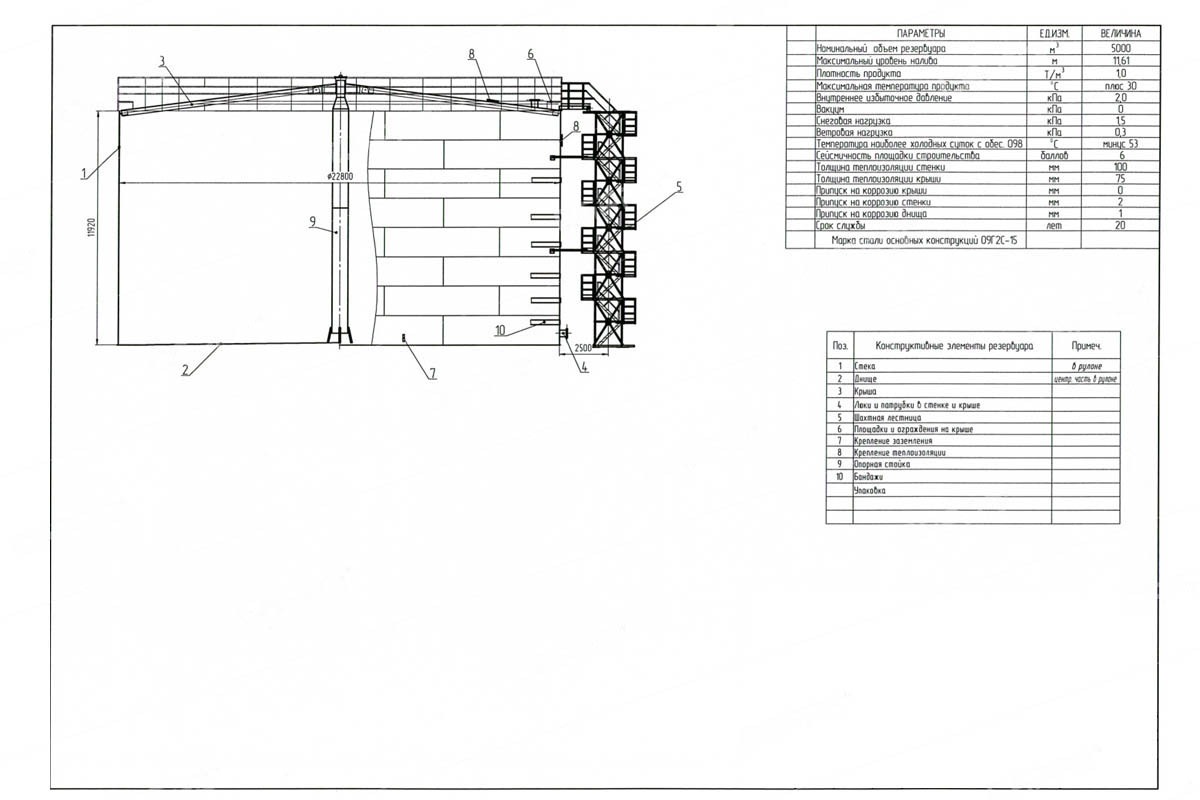

Construction site of VST-5000 in Kemerovo

With the view of the output expansion of chemical fertilizers the Saratov Reservuar Plant has completed a cycle of works on the supply of tank equipment in quantity according to the engineering development programme.

Сonstruction and assembly work was carried out in a markedly continental climate (heavy precipitation seriously hampered the tank erection and paint application).

Due to the high quality level of the work performed SARRZ was able to forge partnerships with the Customer and implement the project in accordance with the approved work specification.

Main specifications:

- Stored product - urea-ammonia liquor;

- VST amount - 3 pcs with a capacity of 5000 m3, 300 m3, 100 m3;

- Material - 09G2S;

- Erection procedure - Roll method;

- Heat insulator (100 mm) and coating (galvanized profiled sheet with a thickness of 0,8 mm) assembly.

Specific features and complexities of the project

The main feature of this project was the execution of the set of works on the supply of three tanks with a volume of 5000 m3, 300 m3, 100 m3, thermal insulation materials (mineral wool boards with a thickness of 100 mm, galvanized sheet with a thickness of 1 mm and profiled sheet with a thickness of 0.8 mm).

The second complexity was the markedly continental climate, which was accompanied by heavy precipitation, which seriously complicated the construction of the tanks and the surface paint application.

Except for chemically resistant coating (DTM) application, the surfaces of stairs, platforms and railings were additionally protected with hot zinc plating against corrosion.

Engineering department of SARRZ has implemented the following scope of works:

- KM project and detailed drawings design development;

- manufacture of vertical tanks coiled sheets;

- delivery of vertical tanks by low roader and railway transport;

- field installation (erection, painting, hydrotesting). Shell heat insulator was made from mineral wool boards with a thickness of 100 mm. Galvanized profiled sheet with a thickness of 0.8 mm was a coating material.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design

Customer feedback

Director-General of Production A.N. Andreev

KAO "Azot" shows appreciation to the specialists of OOO "Saratov Reservuar Plant" for the successful implementation of the project for the installation of a crude oil tank farm, within the framework of which the following activities were carried out: design engineering, manufacture, delivery, assembling of the tanks metal structures VST-5000 m3 in the amount of 2 pcs., anti-corrosion coating application, installation of heat insulator, conducting hydrotests, commissioning of a turnkey facility.

Despite the complexity of the project which had to be finished in a tight deadlines, as well as the difficulties encountered in the course of works and the getting re-approval for the project, all the planned work was carried out in strict accordance with our requirements, and we are very satisfied with their quality. Cooperation with specialists who demonstrated a high standard of professionalism in all types of services provided was constructive and fruitful.

We have experienced the reliability and high quality of the SARRZ work and sincerely recommend this company as a professional, effective and reliable partner.