LPG tank farm construction in Noginsk

Customer: OOO «Soudal Investments»

Location: Noginsk, the Moscow Region

Company sector:

Manufacturer of foams, jointing pastes, adhesives and roofing insulation.

Date of works held:

April 2019 - November 2021

Project:

Tank farm for LPG storage at the manufacturing and storage facility in Noginsk

In order to expand the manufacturing and storage facility, the Saratov Reservoir Factory has implemented a major project for the construction of a tank farm for LPG storage in Noginsk.

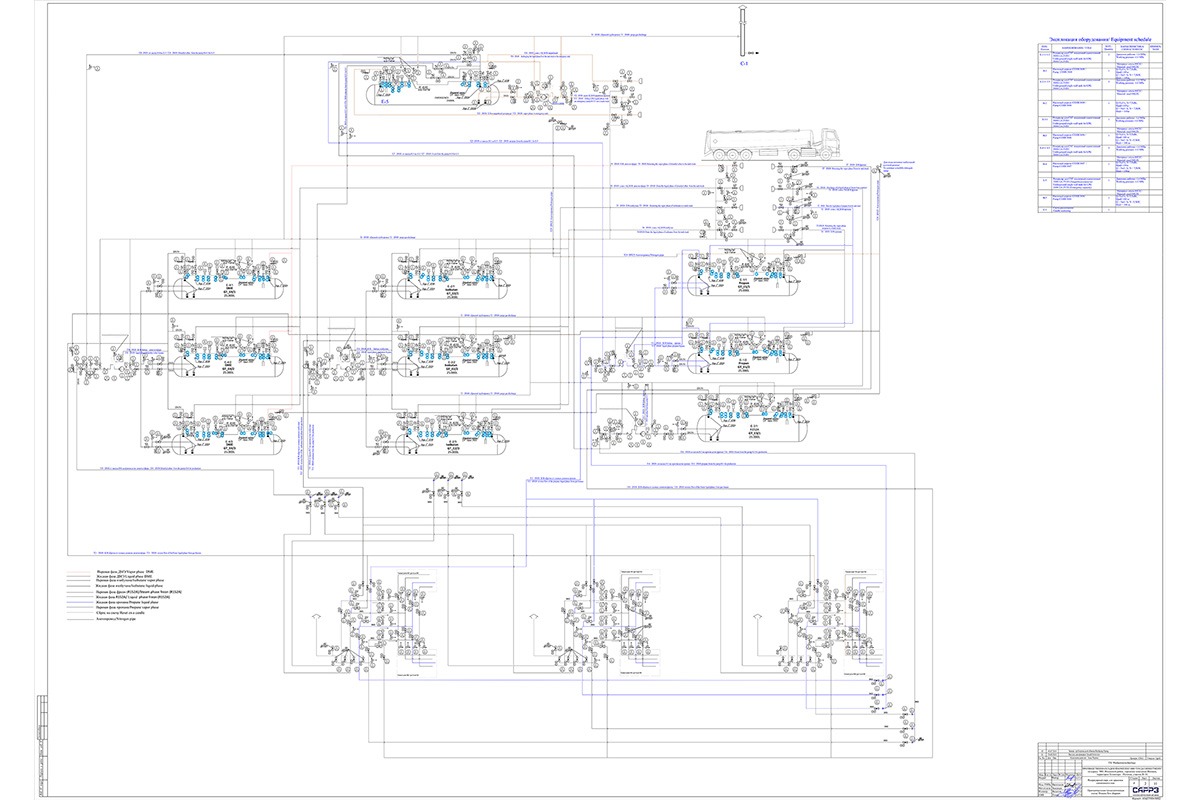

The Engineering Department developed the following detailed designs: the TKh project (engineering solutions), the ECP project (cathodic protection), the ATKh project (Industrial process automation).

To support the process flow of the chemicals production, a engineering solution was developed, which assumed the usage of the following equipment at the facility:

- underground vessel for propane storage with a volume of 25 m3 - 2 pcs.;

- underground vessel for isobutane storage with a volume of 25 m3 - 3 pcs.;

- underground vessel for freon storage with a volume of 25 m3 - 1 pcs.;

- underground double-walled vessel for dimethyl ether with a volume of 25 m3 - 3 pcs.;

- pump for propane - 1 pcs.;

- pump for isobutane - 1 pcs.;

- pump for freon - 1 pcs.;

- pump for DME - 1 pcs.;

- emergency pump - 1 pcs.

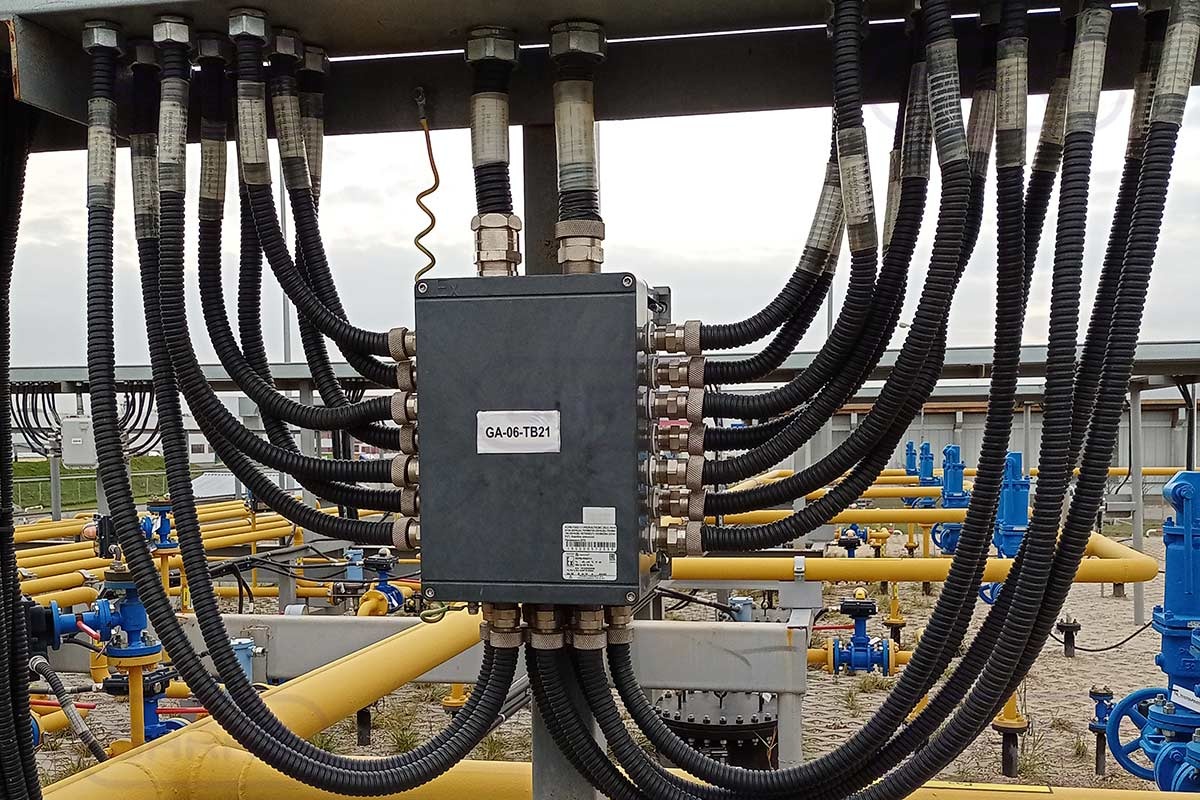

The construction department also carried out in-site process piping.

Main specifications:

- Stored product - propane, isobutane, freon, dimethyl ether;

- Equipment consisting of underground vessels with a volume of 25 m3 each (9 pcs.), pumps (5 pcs.);

- Material of the vessels - 09G2S, material of the in-site gas lines - St10;

- Operating pressure - 1.6 MPa;

- Self-priming pumps characteristics - production capacity 5 m3/h, electric motor power 7.5 kW.

Specific features and complexities of the project

In order to ensure explosion and fire safety at the facility, each vessel is equipped with a discharge vent with the function of connecting to a mobile flare system for emergency venting of vapors (gases) for combustion.

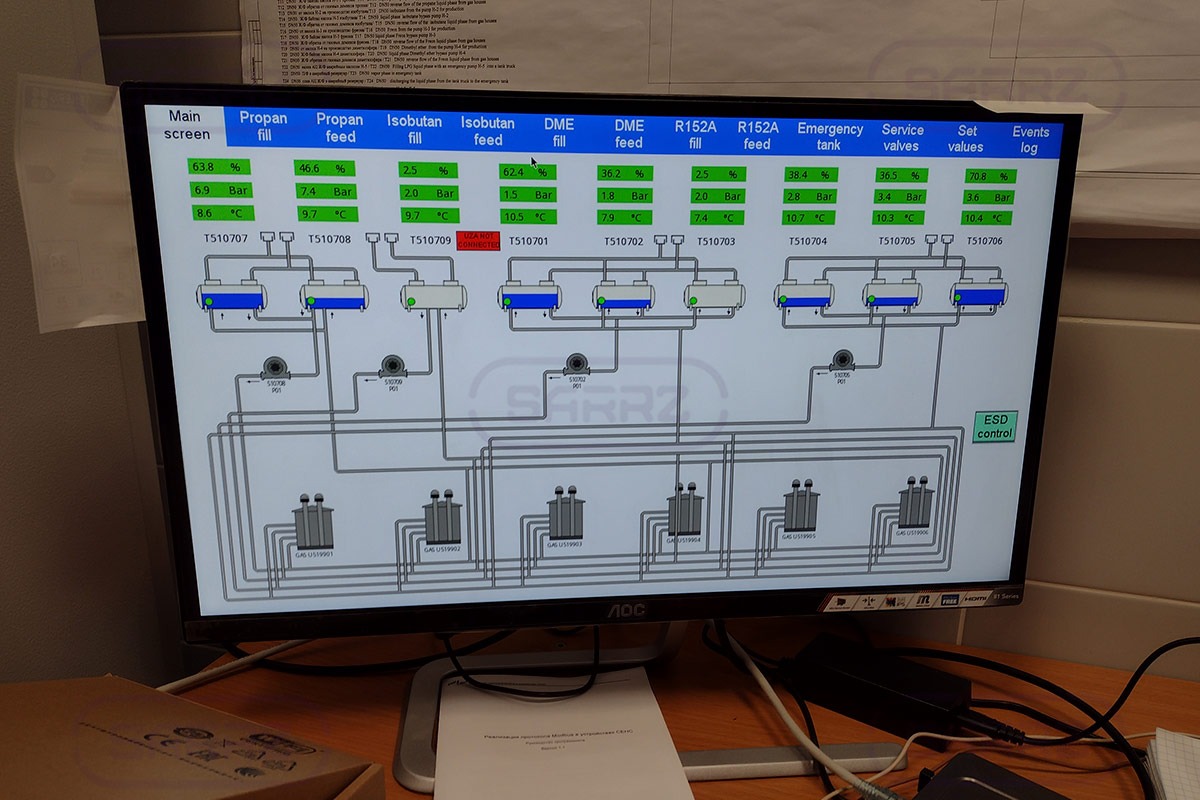

A specially developed process automation diagram is based on the use of Siemens S-7 1500 PLC systems (DCS) and Pilz PNOZ Multi 2 (emergency instrumented protection EIP) with their separation.

Сathodic protection of gas pipelines and vessels is provided with prepacked magnesium protectants connected through a joint protection unit, and reference electrodes with cathodic protection probes monitor the operation of cathodic protection system.

Complex works on the construction of a liquefied gas storage tank farm included:

- development of detailed designs: the TKh project (engineering solutions), the ECP project (cathodic protection), the ATKh project (Industrial process automation);

- fabrication of the vessels in the amount of 9 pcs., provided for by the engineering solutions project, for storage of processing medium involved in the process flow during the dimethyl ether production;

- supply of pumping groups for handling of process media, including emergency;

- installation of underground vessels, aboveground and underground gas pipelines of liquid and vapor phase;

- pre-commissioning activities for placing in operation of the LPG storage tank farm.

Сompleted work

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design