Hydrogen receiver

Description

Hydrogen receivers are installed at metallurgical (for the recovery of metals), chemical (for the synthesis of hydrogen chloride, ammonia, methyl alcohol) and petrochemical (for the hydrogenation of fats, coal and oil) facilities, at atomic energy facilities, in electric generators (for cooling from hydrogen plants), while welding operations of refractory materials, in the space industry (as the most pollution-free fuel of high thermal capacity), etc. They can be either a vessel for storing the final substance, which is delivered directly to the Consumer, and the intermediate vessel, from where the gas is supplied to the further production line.

Construction of hydrogen receivers

The Saratov Reservoir Plant has the necessary Certificates of Conformity for the manufacture of air vessels and receivers.

The Saratov Reservoir plant produces hydrogen receivers,which is designed specifically for this gas. Hydrogen is stored in a compressed state at an excess pressure of up to 12 MPa.

Hard operating conditions predetermined the requirements for the choice of material and design. The main parameters for the design of hydrogen receivers are: volume from 1 to 200 m3 and ultimate pressure (up to 12 MPa). Additional factors affecting the choice of steel and the calculation of the shell thickness are the ambient temperature (above -60°C) and the product temperature (-60°C to + 300°C).

It’s very important to save the tightness over the entire service life. Therefore, accurate calculation and selection of steel, resistant to the chemical effects of the operational product, is required.

For compressed hydrogen storing in safety and durability, we use steel grades that are capable of withstanding internal loads from the pressure and the effects of the stored gas:

- stainless titanium-containing 12X18N10T austenitic class

- corrosion-resistant 10Х17Н13М2Т

- high-strength steel 09G2S

Hydrogen receivers are an above ground horizontal or vertical vessel, which is installed on the supports. This vessels work under high pressure, thats why heads are made elliptical. To perform the basic functions, a hatch, branch pipes and fittings are provided through which filling, pumping, condensate removal, technological inspection and surface cleaning, etc. are carried out.

An important element of hydrogen receivers is a safety valve, which prevents destruction due to pressure increase.

Hydrogen receivers are manufactured from sheet metal, which is given a cylindrical shape. In the shells holes for the hatch (s), fittings and nipples are made. Elliptical heads and supports are made on special equipment. Then all the elements are welded.

The outer and inner surfaces are coated with compounds for additional corrosion protection.

The final stage of production the leakage test, the limiting pressure and resistance to aggressive environments tests. Having the Laboratory, our specialists can guarantee the quality of manufactured products, and highly professional design engineers ensure design accuracy.

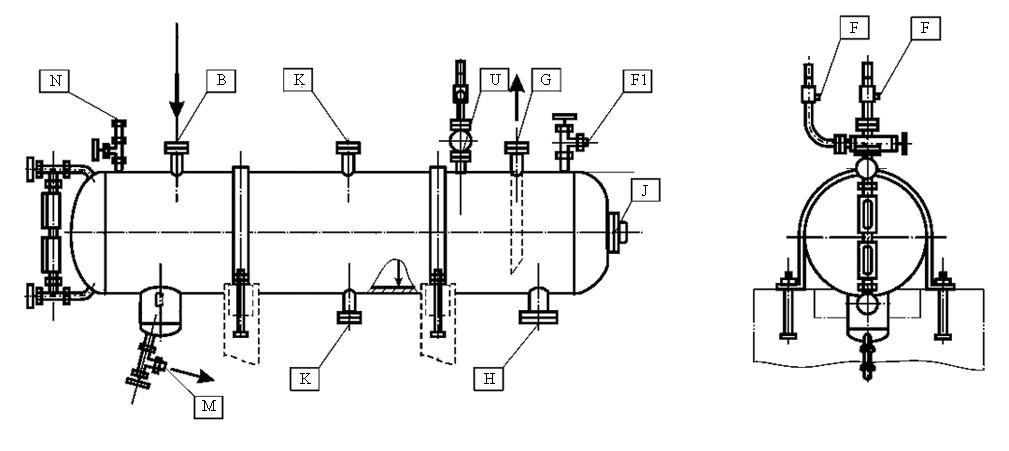

Drawing of hydrogen receiver

Nozzle schedule

| Tag № | Application |

|---|---|

| B | inlet |

| G | outlet |

| K | balance line |

| J | manway |

| M | drainage |

| U | safety valve |

| F | intake |

| F1 | intake |

| H | for pump |

| N | pressure gauge |

The supply package of the hydrogen receiver includes:

- the vessel itself

- set of branch pipes and fittings

- technological equipment (at the Customer's request)

- Product certificate

The summary table of technical characteristics of air vessels and receivers you can see here.

How to order a hydrogen receiver at the Saratov Reservoir Plant?

In order to find out the cost and terms of production of receivers for various gases, You can:

- call at +7(8452)250-288

- press the button "Request for quotation"

- mail in a filled in Questionnaire or information indicating the minimum required parameters for the calculation (operational product, operating conditions, pressure, horizontal / vertical, minimum set of equipment)

Specialists of the Saratov Reservoir Plant perform package services for the construction of oil and gas facilities:

- engineering surveys at the construction site

- construction sites design

- receivers, air vessels and other vessel equipment manufacture

- equipment delivery and installation on site

See also:

| Nitrogen receiver | Oxygen receiver | Compressed Air receivers |

| Argon receivers | Hydrogen receiver |