Compressed Air receivers

Description

Compressed Air receivers are used in pneumatic systems (as an integral part of the compressor station, in gas treatment facilities) at enterprises and technological lines. They provide the uninterrupted supply of the product in the event of production outages or when the consumption exceeds the capacity of the compressor.

Main functions

- accumulation and storage

- surge control in the pneumatic system when the flow rate changes

- pressure maintenance

- ensuring the stable operation of the pneumatic system

- condensate and oil collection and removal

Construction of compressed air receivers

The Saratov Reservoir Plant manufactures horizontal and vertical compressed air receivers. The capacity and the functions performed do not differ. The advantage of vertical receiver is the minimum occupied area, which can be used for other purposes.

Compressed air receiver has a cylindrical shell with elliptical heads. There are branch pipes, fittings and hatches in the shell for the installation of processing equipment, supply and delivery of the operational product, condensate and oil removal and for routine service maintenance or repair.

As the equipment is operated at high pressure (up to 1.2 MPa), they are equipped with control and measuring instruments and safety relief valves that guarantee reliable and safe operation.

Standard equipment includes:

- T-valve pressure gauge

- pressure detectors

- safety relief valve

- measuring instruments

- supply pipeline

- drain tube for steam condensate removal

- fittings and nozzles

Installation of the vessels at the site of operation is carried out on supports.

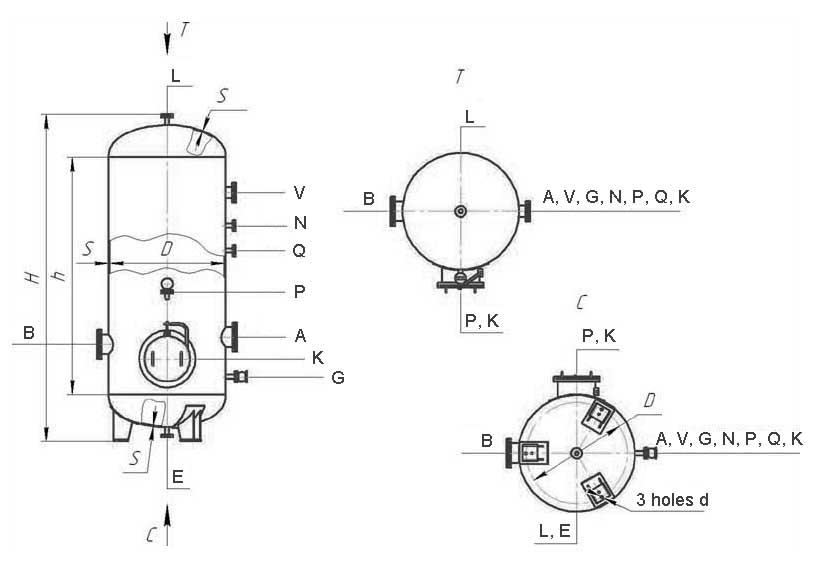

Drawing of compressed air receiver

Nozzle schedule*

| Tag № | Application | Volume, m3 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1,6 | 2 | 3,2 | 4 | 5 | 6,3 | 8 | 10 | 12,5 | 16 | 20 | 25 | 3 | 40 | 50 | ||

| Pipe size , mm | |||||||||||||||||

| А | Inlet | 50 | 100 | 100 | 200 | 200 | 200 | 200 | 250 | 250 | 300 | 300 | 300 | 300 | 350 | 350 | 350 |

| B | Outlet | 50 | 100 | 100 | 200 | 200 | 200 | 200 | 250 | 250 | 300 | 300 | 300 | 30 | 350 | 350 | 350 |

| V | For safety valve | 25 | 50 | 50 | 50 | 80 | 80 | 80 | 150 | 150 | 150 | 150 | 200 | 200 | 200 | 200 | 200 |

| Number of valves | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 1 | 2 | 2 | 3 | 2 | 3 | 4 | 4 | 4 | |

| G | Condensate disposal | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| L | Air vent | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Е | Drainage | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| N | For capacity regulator | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| P | For pressure gauge | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Q | For pressure gauge in the machine room | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| К | Hatch | 80 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 |

Overall size of compressed air receiver with volume up to 50 m3

| Volume, m3 | Main sizes, mm | Weight, kg | |||||

|---|---|---|---|---|---|---|---|

| D | S | H | h | D1 | d | ||

| 0,5 | 600 | 6 | 2000 | 1500 | 520 | 19 | 295 |

| 1 | 800 | 6 | 2340 | 1700 | 720 | 19 | 520 |

| 1,6 | 1000 | 8 | 2300 | 1600 | 920 | 19 | 945 |

| 2 | 1000 | 8 | 2900 | 2200 | 920 | 24 | 1110 |

| 3,2 | 1200 | 8 | 3160 | 2300 | 1100 | 24 | 1420 |

| 4 | 1200 | 8 | 3860 | 3000 | 1100 | 24 | 1655 |

| 5 | 1400 | 10 | 3665 | 2700 | 1260 | 35 | 2170 |

| 6,3 | 1400 | 10 | 4565 | 3600 | 1260 | 35 | 2545 |

| 8 | 1600 | 10 | 4415 | 3300 | 1410 | 35 | 2790 |

| 10 | 1600 | 10 | 5515 | 4400 | 1410 | 35 | 3430 |

| 12,5 | 2000 | 12 | 4520 | 3200 | 1810 | 42 | 4380 |

| 16 | 2000 | 12 | 5520 | 4200 | 1810 | 42 | 5075 |

| 20 | 2000 | 12 | 6870 | 5400 | 1810 | 42 | 6000 |

| 25 | 2200 | 12 | 7155 | 5600 | 2010 | 42 | 7935 |

| 32 | 2400 | 12 | 7775 | 6000 | 2210 | 42 | 9460 |

| 40 | 2400 | 12 | 9775 | 8000 | 2210 | 42 | 12285 |

| 50 | 2400 | 12 | 11775 | 10000 | - | 42 | 14805 |

*The location and purpose of the fittings, as well as the overall dimensions are given for reference

Manufacture of compressed air receivers

The Saratov Reservoir Plant has the necessary Certificates of conformity for the manufacture of air vessels and receivers.

Special wear-resistant steel grades are used for production, which have high strength characteristics to ensure durable and reliable operation. So, we apply steel grades 09G2S, 12H18N10T, 10X17N13M2T.

The inner and outer surfaces are treated with special compositions to protect them from the negative effects of the operational product: they are covered with a primer, galvanic substances, and coated with the powder.

While cost calculation the following is taken into account:

- volume of the stored product

- capacity

- pressure

The summary table of technical characteristics you can see here.

The following advantages of compressed air receivers produced by SARRZ can be listed:

- manufacturer's price

- compliance with the state standards

- availability of certificates

- design department, construction and assemblage department and the logistics department

- tech-heavy production

Ordering of air compressed receivers at the Saratov Reservoir Plant

To calculate the cost of compressed air receivers manufacturing, You can:

- call at +7(8452)250-288

- send the filled in Questionnaire at the e-mail

- use the "Request for quotation", form, provide contact information to call You back

Our specialists perform the entire range of services for compressed air receivers of a volume of up to 200 m3 supply:

- engineering surveys at operation sites

- design and production

- delivery at worksite

- installation and commissioning

See also:

| Nitrogen receiver | Oxygen receiver | Compressed Air receivers |

| Argon receivers | Hydrogen receiver |