Double wall vertical tanks

Description

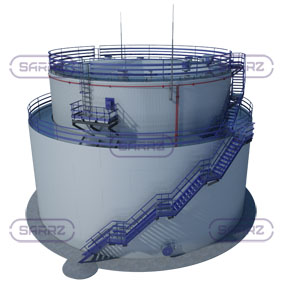

Double-wall vertical tanks designed for storage of light and heavy petroleum products, fuel, gasoline and other non - aggressive liquids are the same vertical tanks (RVS), but have a safety wall. Its purpose and advantage is the additional protection of the environment from leaks of the stored product. In case of depressurization, the stored liquid falls not into the soil, but into the space between the primary and secondary walls. They are recommended to be installed near water bodies, as well as in the crude storages as RVS without dike.

The tanks are manufactured in accordance with the state standards requirements:

- GOST 31385-2016 "Vertical cylindrical steel tanks for oil and petroleum products. General specifications"

- Rules of technical operation of tanks

Design features of double wall vertical tanks

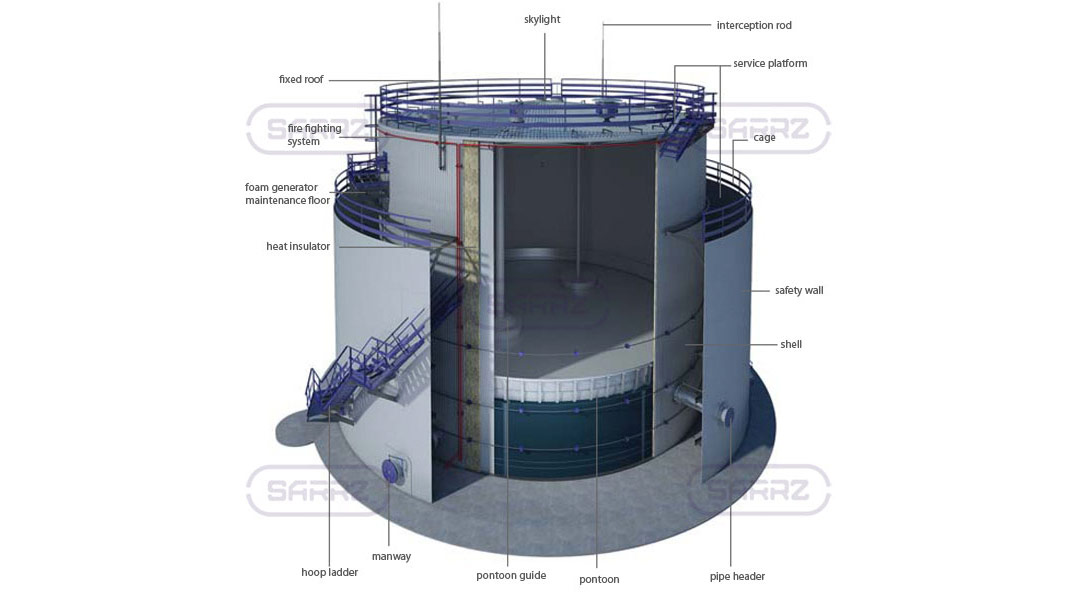

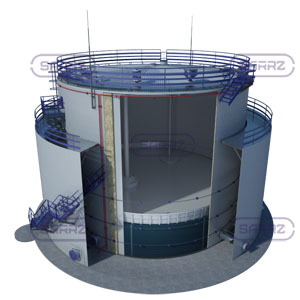

They appear as so-called "a glass in a glass". The inner (primary) shell is a standard cylindrical body with a fixed or floating roof, where the oil product is directly stored. The outer (secondary) shell is a barrier in case of emergency, which is made open without a roof or a pontoon. At the same time, a weather shield is provided to protect the interstitial space from the ingress of debris, sediments and other objects. The interstitial space should be equipped with vent connection.

|

|

To ensure fire and environmental safety, the following rules are taken into account when calculating of diameter and height:

- the distance between the walls should not be less than 1.8 m

- the height of the secondary wall must not be less than 80% of the height of the primary one

In the case of oil products falling into the interstitial space, the liquid filling level should not exceed 1 m up the edge of the secondary wall.

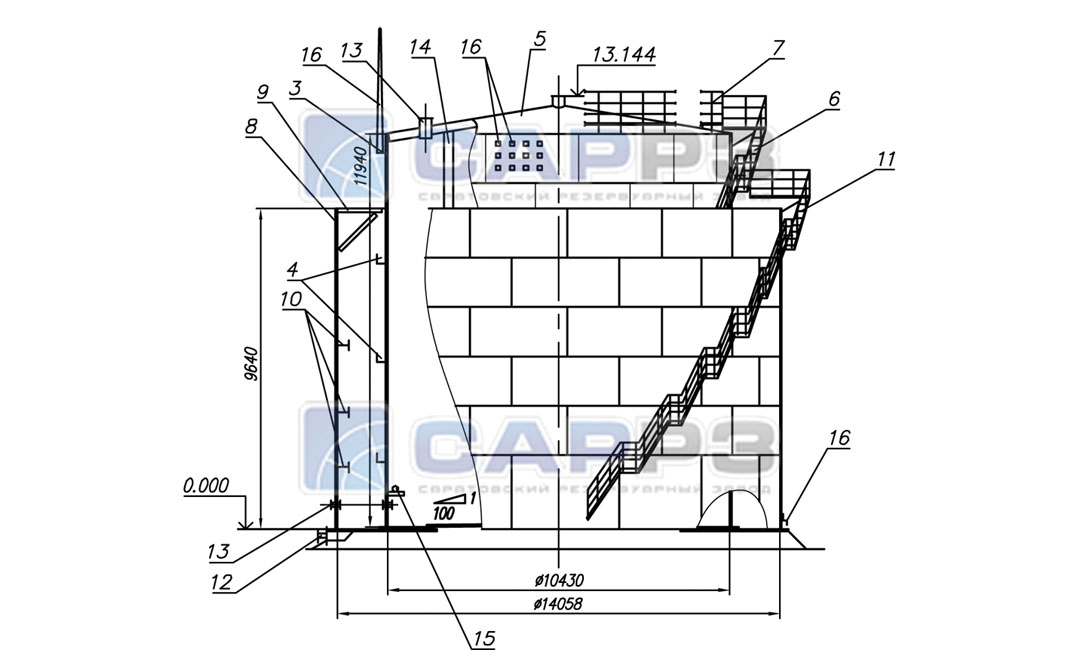

Typical drawing of RVS with a safety wall with a volume of 1000 m3

1-main bottom, 2-protective bottom, 3-inner tank, 4-emergency ropes, 5-roof, 6-ring ladder of the inner tank, 7-access platform, 8-safety shell, 9-wind girder, 10-reinforcing rings, 11-ring ladder of the outer tank, 12-drilling sump of the interstitial space, 13-hatches and branch pipes, 14-stem of the floating sampling apparatus, 15-internal heater, 16-air termination system, electrical earthing, heat insulator fastening

(dimensions are given for reference and are specified by the Customer)

The bottom of the primary tank may rest on by the bottom of the secondary shell or be mounted on the metal lattice work or reinforcing mesh, forming a space between the shells to control the presence or absence of oil leaks. At the same time, the bottom of the safety tank should have a slope only from the center, so that the product trapped in the interstitial space is not deposited at the junction of the bottoms of the outer and inner shells (if the inner bottom rests directly on the outer) or accumulates in the center of the safety tank (if the inner bottom rests on metal lattice work).

The structure of the secondary shell provides inspection hatches or manholes for access to the interstitial space. Also two ladders are equipped: one - on the inner tank, the second - on the outer tank.

Manufacture of vertical tanks with safety shell

Design and manufacture are carried out in accordance with the state standard GOST 31385-2016 "Vertical cylindrical steel tanks for oil and petroleum products. General specifications". The Plant SARRS performs the production of double-wall vertical tanks with volume up to 20000 m3.

Double-wall tanks RVS can be produced by a rolling or by plate-by-plate methods. The production process is selected according to the volume: tanks of a small volume are produced by the rolling method, of a large volume - by plate-by-plate method.

To manufacture double-wall vertical tanks various steel grades are used depending on operating conditions (a temperature, seismicity of the operation area) and characteristics of the stored product. The thickness of the steel depends on the volume of the tank: the larger, and accordingly, the higher, the thicker the metal is used for the lower rings to maintain vertical stability . It is also necessary to consider corrosion allowance of rolled steel depending on operating conditions.

The summary table of technical characteristics of RVS vertical tanks can be found here.

How to order and purchase a double-wall vertical tank?

To enquire the cost of a vertical tank with a safety shell, You can:

- call at 8(8452)250-288

- send the filled Questionnaire to e - mail

- use the form "Request for quotation", specify the contact details to call You back

We perform package of services: design of double-wall vertical tanks, equipment arrangement, manufacture and erection.

See also:

| Double wall vertical tanks |