Double-wall horizontal tanks

Double-wall horizontal tanks are used to store liquids in the gas and oil refining and petrochemical industries: light and heavy petroleum products, oil, chemicals, condensate, acids, diesel fuel, solvents, coolants, mineral fertilizers, mixtures from process pipelines, as well as technical and drinking water.

Manufacture of double-wall horizontal tanks

Their production is carried out in accordance with the permits and Certificates.

They are fabricated in two structural designs: aboveground and underground. The method of placement depends on the tasks assigned and on the operating conditions. Aboveground double-wall tanks are more often used to receive, store and dispense crude oil after the first stage of treatment, semi-finished products of oil refining, cracking products, hydrocarbons. Underground double-wall tanks are used at a fueling filling station for storing fuel.

Our plant produces double-wall horizontal tanks with a volume from 5 m3 to 200 m3 for storage operational products with temperature from -15°C to + 270°C, density not exceeding 1 t/m3 and operating pressure up to 0.07 MPa.

Depending on the operating conditions, double-walled vessels can be made of the following steel grades:

- version 1 of St3sp - operating temperature up to -20°С

- version 2 of 09G2S - up to -40°С

- version 3 of 09G2S - up to -60°С

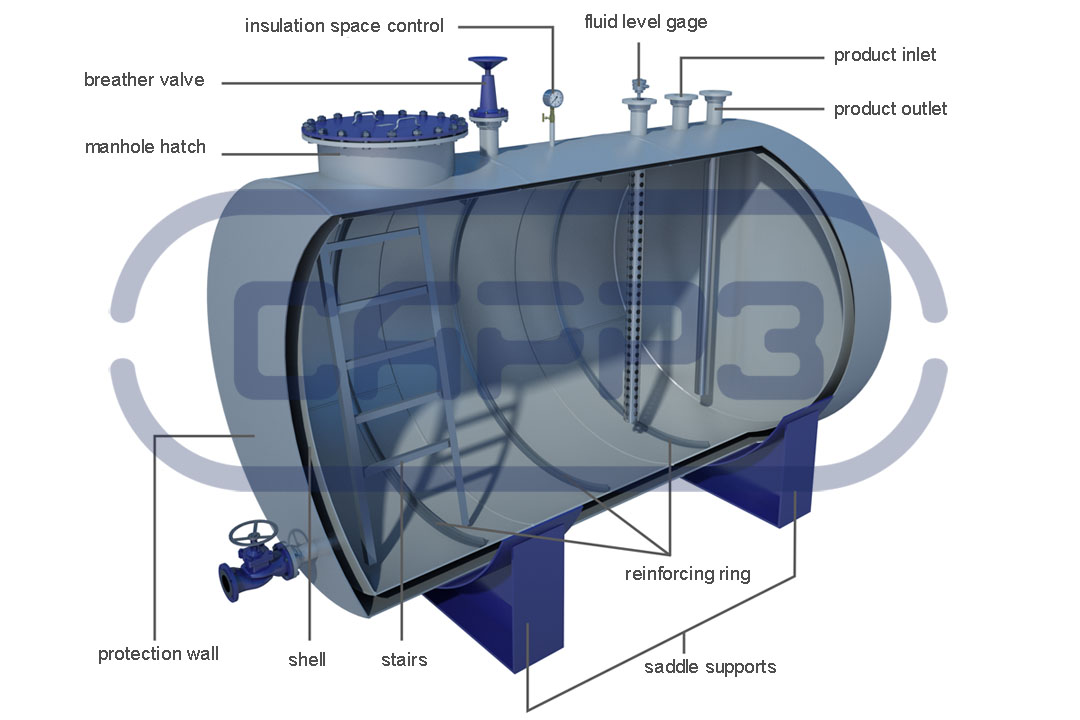

Construction of double-wall horizontal tanks

Their design consists of two tanks (internal and external), located one in the other. The insulation space is filled with antifreeze or nitrogen gas. The distance between the shells should not be less than 4 mm. The thickness of the internal tank shell shall not be less than 4 mm. The thickness of the external tank shell shall not be less than 5 mm.

Hatches, fittings and necks are installed after welding all the seams. Depending on the aboveground or underground location, the surfaces are treated with a suitable coating.

To ensure safety, there are the following requirements applied to the interstitial fluid:

- it should not have a density greater than the density of the stored product

- flash point not lower than 100°С

- the liquid must have chemically neutral characteristics with respect to materials

- the liquid should not change the chemical and physical properties for the entire life of the product

Liquid is drained from the insulation space by a pumping-out system.

Double-wall construction contributes higher environmental safety of petroleum and other operational products storage. Except technical equipment, the insulation space filled with nitrogen is another barrier in the event of fire and explosive emergencies and leaks.

Installation of ground and underground double-wall horizontal tanks

Underground double-wall tanks are mounted inside foundation pit on the prepared soil or on reinforced concrete slab, below the freezing level of the ground, which is an additional thermal insulation and prevents the freezing of the stored product.

All tank’s necks and pipes should be 200 mm above the ground surface.

Underground tanks have better waterproofing insulation of the shells to prevent oil products from entering the ground.

The technological compartment is telescopic so that it is possible to adjust the depth of the installation.

The outer tank shell is treated with an anti-corrosion and waterproofing coating which protect from groundwater.

Aboveground double-wall tanks are installed on supports that are attached from one side to the embedded parts of the foundation plate, and on the other to the metal structure by anchorages.

The outer tank shell is usually covered with a primer and enamel.

Complete set of double-wall horizontal tanks

The main equipment necessary for reliable and safe operation are measuring instruments: level gauges, vapor detectors and devices for oil products draining and filling.

It is very important to monitor the excess fluid pressure in the insulation space. It should not be more then 0.001 MPa. Decrease in pressure signals the possible entry of the stored product into the insulation space.

The signal of the vapor warning sensors, which are installed on the tanks neck, also may indicate possible depressurization.

The installation of automatic level gauges and gaging rod enables to determinate filling level of oil products. It is also recommended to use special quipment to prevent overfilling of the maximum possible filling level.

The Saratov Reservoir Plant uses the latest technologies for the production of double-wall vessels. All products undergo quality control, leak tests and others. After product acceptance the tanks are supplied and installed.

How to calculate the cost of double-wall tanks manufacturing at the Saratov Reservoir Plant?

To order the manufacture of double-wall horizontal tanks you can:

- send us the technical specification or filled Questionnaire by e-mail

- call at +7(8452)250-288

- use the "Request for quotation", form, provide contact information, and our specialist will contact you

The Saratov Reservoir Plant carries out package of services at manufacturer's price. We offer:

- engineering surveys at the site

- design of the oil and gas industry facilities

- production of double-wall tanks with a capacity of up to 200 m3

- installation and commissioning of the site