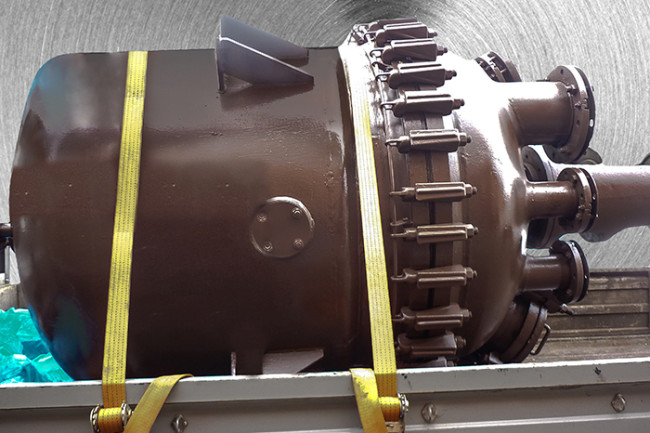

Stirred vessels

Stirred vessels are the vessels with agitators which are used for operation with viscous liquid products with viscosity up to 200 Pa x s. The stored product is mixed in them to process emulsification, suspension, homogenization, chemical reactions, etc.

Vessels with agitators are wildly used in many industries, for example, as chemical or bioreactors, for grinding and mixing paints and toners, for the production of wine materials.

When they are operated at a temperature below 0°C, the construction is provided with heat-exchange equipment - a coil or «jacket» which enables to prevent freezing of the liquid.

In accordance with GOST 20680-2002 “Stirred vessels. General technical specifications” the vessels with mixers have the following characteristics:

- volume from 1 m3 to 100 m3

- medium density up to 2000 kg/m3

- operational product - single-phase and multiphase, neutral, aggressive, fire-hazardous, explosive, toxic liquids, emulsions, gas-liquid mixtures or suspensions with mass concentration of solids not more than 30%

- temperature from -40°C to + 350°C

- pressure up to 6.3 MPa

- pressure in the jacket (if available) - up to 1.6 MPa

- medium in the jacket (if available) - water, saturated water vapor, antifreeze, condensate, organic coolant

- the temperature of the heat conductor in the jacket (if available) - from -30°C to + 250°C

- seismicity of the operational area - up to 6 points

Construction of stirred vessels

They are manufactured in vertical design. The housing is a cylindrical all-welded or split container with elliptical, conical or flat heads and lids.

The Saratov Reservoir Plant manufactures vessels with agitators of following structural designs:

- with elliptical head and elliptical split head

- all-welded with elliptical head and head

- with a conical head, a cone angle of 90° and an elliptical split head

- all-welded with a conical head, a cone angle of 90° and an elliptical head

- with elliptical head and flat split head

- all-welded with elliptical head and flat head

- with a conical head, a cone angle of 120° and a flat split head

- all-welded with a conical head, a cone angle of 120° and a flat head

- with flat head and flat split head

- all-welded with flat head and head

(the specifics of the structural designs can be found in the corresponding sections)

A feature of stirred vessel is the presence of a mechanical agitator. Depending on the properties of the operational product, we supply different types of agitators:

- blade, gear turbine, gate mixers (for media with viscosity up to 50 Pa x s)

- spiral agitator and ribbon-blade mixers (for media with viscosity more than 50 Pa х s)

The vessels are also equiped with:

- control instrumentation

- safety equipment

- shutoff and control valves

- filling and discharge branch pipes

- automatic control and regulation system

- hatches (with a device diameter of more than 800 mm)

- grounding system

Pressure integrity is gained due to end or gland seals, the choice of which depends on the properties of the operational fluid.

Manufacture of vertical stirred vessels at the Saratov Reservoir Plant

Certificates and other permits for the design, manufacture and installation of stirred vessels You can see here.

Vessels with agitators design and manufacture is based on the following characteristics:

- pressure

- volume

- temperature

- type of agitator and rotational speed

- engine power

The material of the main structures is selected proceeding from the chemical properties of the operational product (viscosity, density, temperature), as well as climatic service conditions. First of all the material of the shell must be chemically and corrosion-resistant, capable of withstanding the effects of aggressive media.

We produce vessels with agitators from alloyed (12Х18Н10Т, 10Х17Н13М2Т), carbon (st3, st20, 09G2S) and stainless steel grades and titanium alloys.

Ordering of vertical vessel with agitators (stirred vessel) at the Saratov Reservoir Plant

To calculate the cost of stirred vessel manufacturing, You can:

- call at +7(8452)250-288

- send filled in Questionnaire at the e-mail

- use the "Request for quotation" form

Specialists of the Plant perform package of services:

- supply of oil and gas facilities with tanks and vessel of our own production

- engineering survey

- oil industry facilities design

- installation of the supplied equipment