Water settling tanks OW

Description

Water settling tanks OW are oilfield equipment that is used to purify oilfield water from oil, gas and mechanical impurities. Purified water may later be used for technological needs.

Design and internal arrangement of water settling tanks

This type of equipment is manufactured in a horizontal design and is an all-welded cylindrical container with elliptical heads on supports. The Saratov Reservoir Plant produces water settling tanks with a volume of up to 200 m3.

The inner surface is treated with anticorrosive coatings that allows the tanks to operate for up to 20 years.

At the facility, settling tanks are mounted on a reinforced concrete foundation at grade. The period of installation work is reduced due to the full factory readiness of the supplied settling tanks: all the technological equipment is pre-installed.

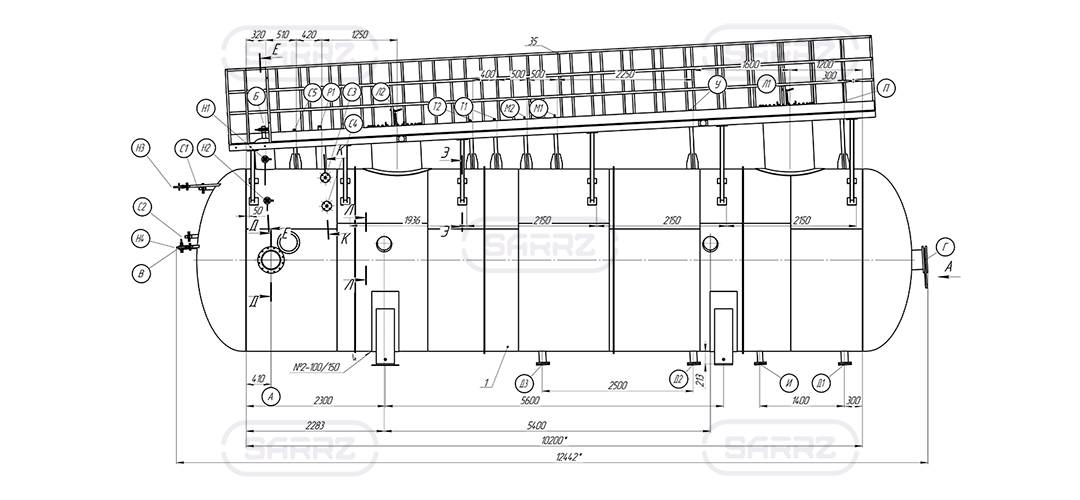

Water settling tanks are equipped with a level gauge, temperature sensor, thermometer, pressure gauge, pressure sensor, safety valve, upper level alarm. There are fittings around the shell through which the oilfield water is supplied, captured oil is collected, gas is diverted and already treated water is discharged. The settled sludge is removed through the stripping hole. Fittings for steaming and ventilation are also provided. The access inside the tank is provided through a manhole.

The vessel is always filled with water. Initial liquid supply may be carried out both from above and from below. The principle of operation of water settling tanks is based on the action of gravitational forces. Due to the different density of the oil and gas particles remain on the surface, the purified water is collected under a hydrophobic layer formed by the interface line of the media. Mechanical impurities settle in the lower part of the tank.

Water settling tank OW 80 m3 with mechanical impurities drawing

Nozzle schedule

| Designation | Assignment |

|---|---|

| А | produced water inlet |

| Б | gas outlet |

| В | oil outlet |

| Г | treated water outlet |

| Д1 | drainage |

| Д2, Д3 | sludge discharge |

| И | water for sludge washout inlet |

| Л1, Л2 | manhole |

| М1 | pressure gauge |

| М2 | pressure sensor |

| Н1...Н4 | visual level gauge |

| П | steaming |

| Р1 | level gauge |

| С1...С5 | level alarm |

| Т1 | temperature probe |

| Т2 | temperature sensor |

| У | safety valve |

Water settling tanks performance capability

| Criteria | Value |

|---|---|

| Processing medium | oilfield water with oil, gas and mechanical impurities |

| Capacity, m3 | 50-200 |

| Material | 16GS, 09G2S |

| Processing capacity, m3/day | 2000-15000 |

| Outlet oil-in-water content, mg/l | 30-40 |

| The contents of mechanical impurities in treated water, mg/l | up to 20 |

| Process pressure, MPa | 1.0; 1.6; 2.5 |

| Operating medium temperature, ºС | -60...+100 |

| Ambient temperature, ºС | -60...+50 |

| Climatic category | NF |

| Seismicity, points | up to 8 (more than 8 at special order) |

| Service life, years | up to 20 |

How to buy water settling tank?

In order to purchase water settling tank You may:

- call at +7(8452)250-288

- email at

Our Plant offers the following:

- high quality of the supplied equipment, which guarantees reliable and safe operation

- individual approach when calculating equipment

- favorable terms of cooperation

- individual delivery conditions when applying for a set of separation and storage equipment

See also: