Water degassing buffer BDV

Description

Water degassing buffers BDV are used in the oil and gas producers and other enterprises for produced water treatment at oil preliminary processing and initial water separation facilities. Their use allows to purify water from mechanical impurities, associated gas and oil emulsion.

The use of water degassing buffers in the process chain of oil production ensures the subsequent use of water in production needs.

Functionality of water degassing buffers

- degassing of produced water

- impurity removal

- gathering and removal of associated petroleum gas and emulsified oil

- clean water discharge

Design of water degassing buffers

They appear as horizontal cylindrical vessels with elliptical heads. Their installation is carried out only aboveground on support-legs or support-lugs. Depending on the volume the Saratov Reservoir Plant manufactures the following structural designs:

- on the frame: the vessel is mounted and fastened to the metal frame for easy transportation and transfer to the operating site if required

- in block-modular design: vessel, piping, pumps and other processing equipment is placed in a stationary block-module of sandwich panels

It is also possible to supply ladders, service platforms and other metal structures.

There are manholes and pipes in the body which provide access to the interior, maintenance, produced water loading and discharge, gas and oil emulsion collection and withdrawal, and the instrument installation (pressure gauges, level gauges, sensors, safety valves, etc.).

Inside there are the distributors and coalescing filters for water purification. First oil is captured and removed from the operating product. Then the gas is out and condensed moisture is trapped. At the outlet produced water with the necessary physical and chemical characteristics is discharged.

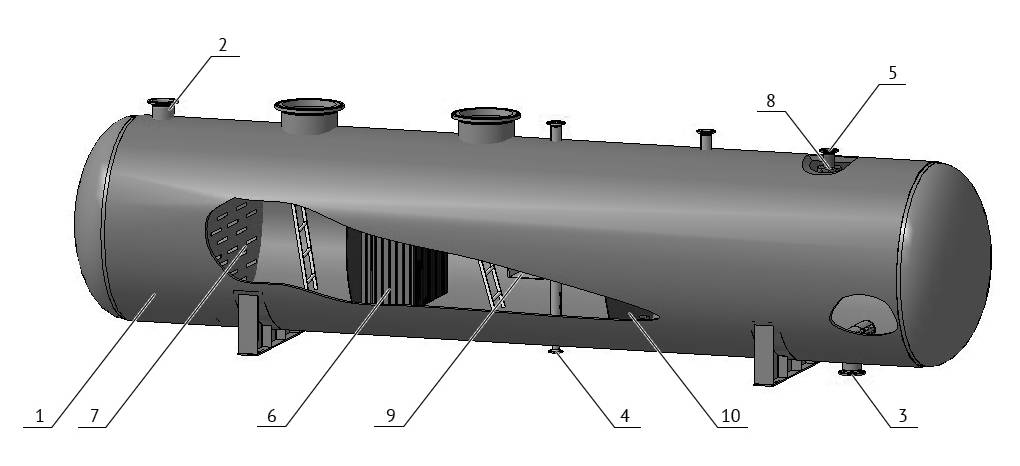

Scheme of water degassing buffer

1-body, 2-produced water inlet, 3-water outlet, 4-oil outlet, 5- gas outlet, 6-coalescing filters unit, 7-coalescence and distributor device , 8-dripping liquid trapping device, 9-device for collecting of captured oil, 10-high-level weir

Characteristics of water degassing buffers BDV

- volume - from 12 m3 to 200 m3

- pressure - 0.6-1.0 MPa

- liquid capacity-500-8000 m3/day

Design, volume, overall dimensions and layout of process equipment depends on several factors:

- required performance

- physicochemical properties of the raw liquid

- performance requirements to the liquid at the outlet

- mode of operation

Manufacture of water degassing buffers

Our Plant has the necessary Certificates of conformity for the manufacture of oil and gas tanks, vessels and separators.

Water degassing buffers are made only of highly resistant steel grades, which can be subjected to corrosive environment. To protect the inner surface special anticorrosive materials are used, which are applied to the surface after sandblasting, which ensures uniform coating.

After accomplishment of automatic and manual welding weld inspection, leak and high pressure tests should be done.

The delivery package includes the Product certificate, which specifies all the technical parameters and which guarantees the quality.

The advantages of water degassing buffers manufactured by SARRZ

Manufacturing of water degassing buffers is carried out on the high-quality equipment that provides safe operation throughout all service life. Only materials which are able to endure high stress of aggressive operating liquid are selected for manufacturing. Due to the well-thought-out system of arrangement of buffer internals, namely coalescing filter, the necessary purification efficiency is provided. A feature of the water degassing buffer design is the ability to implement three processes simultaneously: produced water purification, knocking down the oil/gas and oil/gas collection.

Summary tables of technical characteristics of oil and gas separators and sedimentation tanks can be found here.

How to order a water degassing buffers at the Plant?

In order to buy a water degassing buffer, You can:

- call at +7(8452)250-288

- e-mail at technical requirements information

- download and fill the Questionnaire and then send it by e-mail

- use the form "Request for quotation", and our Manager will contact you

The Saratov Reservoir Plant also perform services of separators and vessels installation and commissioning. We offer packaged supply of separation equipment for Your industrial enterprise on individual order and favorable terms.

See also: