Gas separators

Description

Gas separators are the obligatory equipment in processing train at the enterprises of natural gas, oil and gas production, processing and storage, as well as chemical enterprises. They perform the function of preliminary treatment of natural or associated petroleum gas from mechanical impurities, condensate, oil, drip moisture before its subsequent processing or before transportation through trunk pipelines. Also they are a part of installations of preliminary gas and oil processing terminal, gas purification systems, water discharge systems.

Gas separator configuration

We manufacture gas separators in two structural designs:

- SGG - horizontal

- SGV - vertical

Their main difference is in the installation method, while having the same efficiency of gas cleaning.

Gas separators appear as vertical or horizontal cylindrical vessels with elliptical heads. Regardless of the installation method they are installed aboveground on the supports-legs or supports-lugs.

There are manholes and connection pipes in the shell for gas supplying, the condensate removal, the access to the inside and equipment assembly (pressure gauges, sensors, level gauges, valves, instrumentation). The arrangement of nozzles and the equipment configuration is selected individually on the basis of the operating specifications (pressure, gas properties at the inlet, the requirements for its parameters at the outlet).

At the Customer's request we manufacture other structural variations:

- with thermal insulation to maintain the working temperature

- on the channel frame: the separation unit includes the vessel itself, piping with a set of isolation valves and safety devices which are attached to the frame

- modular gas separation systems: the vessel itself, piping, a set of shut-off and safety valves and other equipment if requested (for example, pumps) are placed in a heat-insulated block-box of sandwich panels

Inside there is a block of coalescing filters on which moisture particles and mechanical impurities settle down.

Operation of vertical and horizontal gas separators SGV and SGG

They are the devices of the inertial-filtering type, because the separation of the condensed moisture, condensation and mechanical impurities is carried out by gathering of the particles on a special coalescent filters. These filters are plates that arrest droplets or particles due to the pressure decline. Further settled particles are gathered and discharged through the head nozzle.

The efficiency of this form of treatment is up to 99%, which ensures high quality of gas treatment.

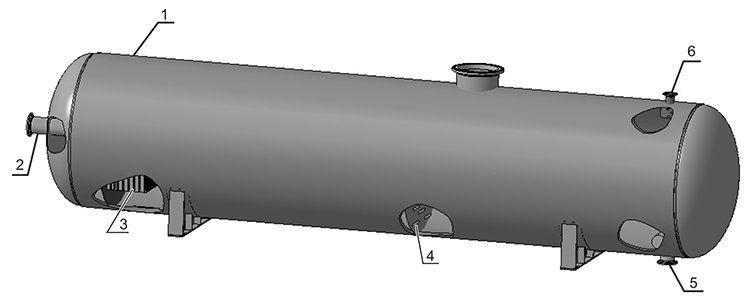

The horizontal gas separator SGG scheme

1-housing, 2-gas inlet, 3-coalescing filters unit, 4-distribution and coalescence device, 5-gas condensate outlet, 6-gas outlet with dripping liquid settling device

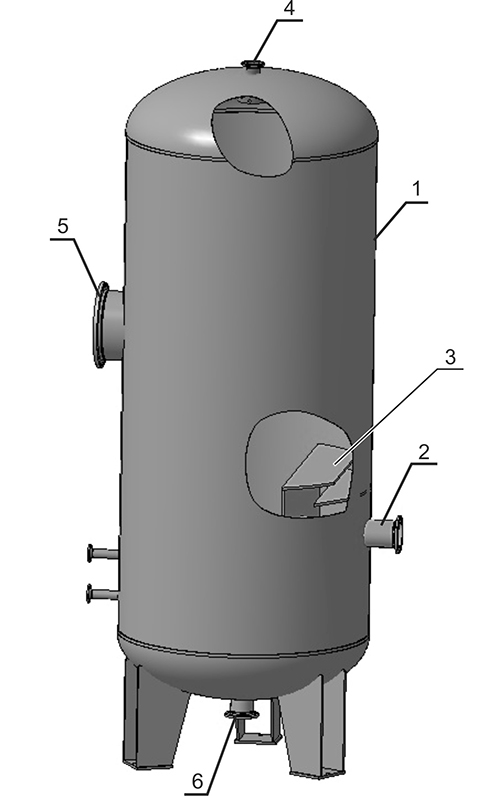

Scheme of the vertical gas separator SGV

1-housing, 2-gas inlet, 3-distribution and coalescence device, 4-gas outlet with dripping liquid settling device, 5-manhole, 6-gas condensate outlet

Technical specifications of the gas separators

- the volume - 0.6 to 100 m3

- pressure - 0.4 - 4.0 MPa

- product capacity-5000-700000 Nm3/h

Production of horizontal and vertical gas separators

The Saratov Reservoir Plant has the necessary Certificates of conformity for the separation equipment manufacturing.

The quality of the gas separators manufactured is guaranteed due to the rolled steel, a degree of technological effectiveness of the equipment and personnel qualification. We fabricate gas separators according to standard drawings and individual orders, using modern design programs and manufacturing process. All stages are controlled by the Quality Control Division.

The manufacturing process consists of several stages:

- preshaping of shells, heads, pipes, hatches, ladders, service platforms, frame construction

- manual or automatic welding of all the elements

- weld inspection, leak testing and high pressure test

- sandblasting of all metal surfaces for the subsequent corrosion protection coating application

- anti-corrosion treatment of external and internal surfaces (if requested)

All the carried-out works are documented by final completion protocols. At the end of the manufacturing process Product certificate is issued, confirming the quality of products supplied (together with the Certificates of conformity for the used metal).

Advantages of gas separators manufactured at the Saratov Reservoir Plant

- high degree of gas separation due to the use of special coalescing filters regardless of pressure

- high performance due to simple but effective design

- the use in the flowing and plug gas flow

- individual manufacturing according to all the requirements

Summary tables of technical characteristics of oil and gas separators and sedimentation tanks can be found here.

How to order gas separators?

To calculate the cost and purchase the SGV/SGG gas separator, You can:

- call at +7(8452)250-288

- e-mail technical requirements or the filled-in Questionnaire

- use the form "Request for quotation", and our specialist contact You

Our Plant fabricates any separation plants necessary for gas purification. When ordering a set of equipment, we offer individual terms of cooperation.

See also: