Advanced water filtration vessels UOV

Description

Advanced water filtration vessels (UOV) are used at oil and gas production facilities for fine purification of oilfield water, which is recovered in parallel with oil, from emulsified oil and mechanical impurities. Treated water can be further used in various technological needs at the same facility (for example, in the flooding system).

The functions of the advanced water filtration vessels

- full water treatment (fine) takes place in one unit, reducing cleaning time, processing area and operating costs

- higher quality of water treatment (compared with the use of a number of devices in the same technological line)

- contents of delivery includes a system of head sediments washing, which significantly reduces the need for routine maintenance and reduces the formation of stagnant zones, which affects the total product capacity

Configuration of the advanced water filtration vessels

They appear as a horizontal cylindrical housing with elliptical heads.These vessels are mounted aboveground on leg-supports or lug-supports, the number and type of which depends on the volume and properties of the soil at the site. At the Customer's request the Saratov Reservoir Plant supplies vessels for fine purification of oilfield water of small volume on metal frame or in modular design (the heat-insulated block-box).

There are hatches, fittings and pipes through which the loading of the vessel, the discharge of captured oil and gas, the discharge of treated water, as well as the installation of process equipment (equipment for head sediments washing, Instrumentation, etc.).

A ladder and a service platform which provide access of service personnel to the hatches located at the top of a vessel is supplied at the Customer's request.

There are coalescing nozzles (filters) inside the vessel that allow oil and gas fractions and mechanical impurities to settle on them. Water inlet is performed through the lower pipe, located in the center of the housing. Water treatment is carried out in two directions, which increases product capacity.

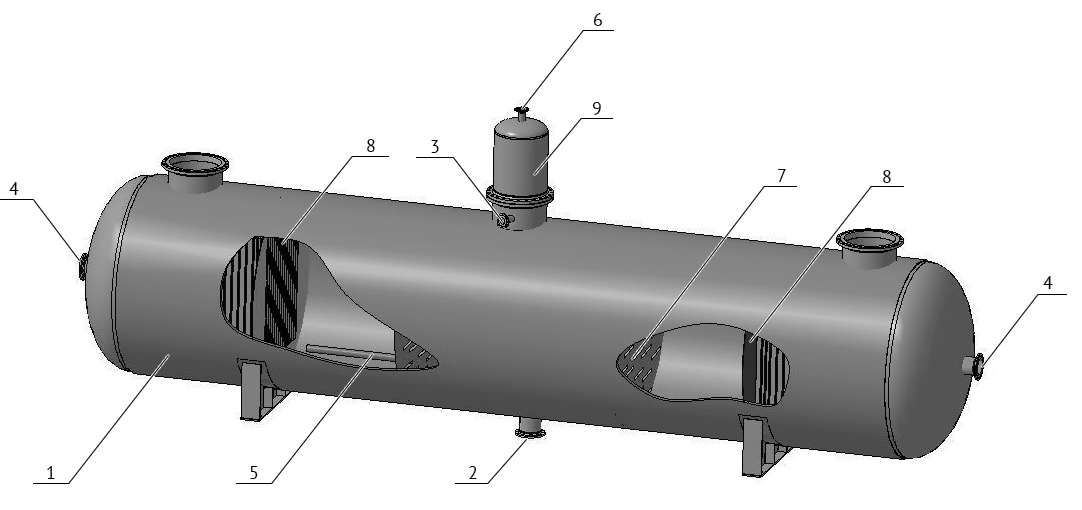

Scheme of the advanced water filtration vessels UOV

1-housing, 2 - inlet of the raw liquid, 3 - outlet of the entrapped oil, 4-water discharge, 5-system of head sediments washing, 6-gas outlet, 7-distribution and coalescence, 8 - block of coalescing nozzles, 9-coalescent filters package

Characteristics of advanced water filtration vessels

- volume - from 12 m3 to 200 m3

- product capacity - 1,000-10.000 m3/day

- operating pressure — 0.6-1.6 MPa

- the oil content in the inlet water - up to 100 mg/l

- number of mechanical impurities at the inlet - up to 100 mg/l

- the oil content at the outlet - 15-25 mg/l

- the content of impurities at the outlet - 15-20 mg/l

The manufacture of the advanced water filtration vessels UOV

The Saratov Reservoir Plant has the necessary Certificates of conformity for the oil and gas tanks and separators manufacturing.

Manufacture is carried out on the hi-tech equipment and compliance with the Industrial Safety Regulations and the state standards.

Particular attention is paid to the selection of steel grades and corrosion protection in the manufacturing process.

To select a steel grade, the properties of the working medium (corrosion characteristics and aggressivity) and pressure are taken into account. Due to these, the steel must be resistant to corrosion. Additional reliability is given by special compositions for surface protection. After welding of all elements welding test, leak test and high-pressure test are performed. For even application of protective compounds sandblasting is carried out.

Only highly qualified specialists who regularly undergo refresher courses perform all the works. The Plant's management believes that the safety and reliability of manufactured products depend on three factors: the materials and the technologies used and the skills of workers.

All stages of manufacture are accompanied by the final completion protocols. When delivering the equipment, the Customer also receives the product certificate, which is a guarantee of vessels quality.

Summary tables of technical characteristics of oil and gas separators and sedimentation tanks can be found here.

How to order an advanced water filtration vessels UOV at the Saratov Reservoir Plant?

In order to buy a vessel, You can:

- call at +7(8452)250-288

- send an e-mail with the information about your requirements at

- download the Questionnaire, fill it in and e-mail it

- use the form "Request for quotation": fill in the contact information, and our specialist will call you back

Plant SARRS perform package of services for oil enterprises: oil and gas separators and sedimentation tanks, Integrated Oil and Gas Treatment Units and water treatment vessels, etc. We also undertake mounting and commissioning of the equipment produced. In case of complex delivery we offer individual terms of cooperation.

See also: