VST-5000 erection in Biysk

Customer: CPZ Azot

Location: Biysk, Altai Territory

Company sector:

Production and sale of liquid fertilizers

Date of works held: August 2020 - December 2020

Project:

Tank erection for liquid fertilizer storage

The Saratov Reservoir Plant manufactured the VST-5000 to ensure the raw material reserve of the Customer's facility. Currently, construction and assembly operations have been completed at the facility.

Due to the high level of service level performed SARRZ has implemented the project in accordance with the agreed technical specifications for execution of works.

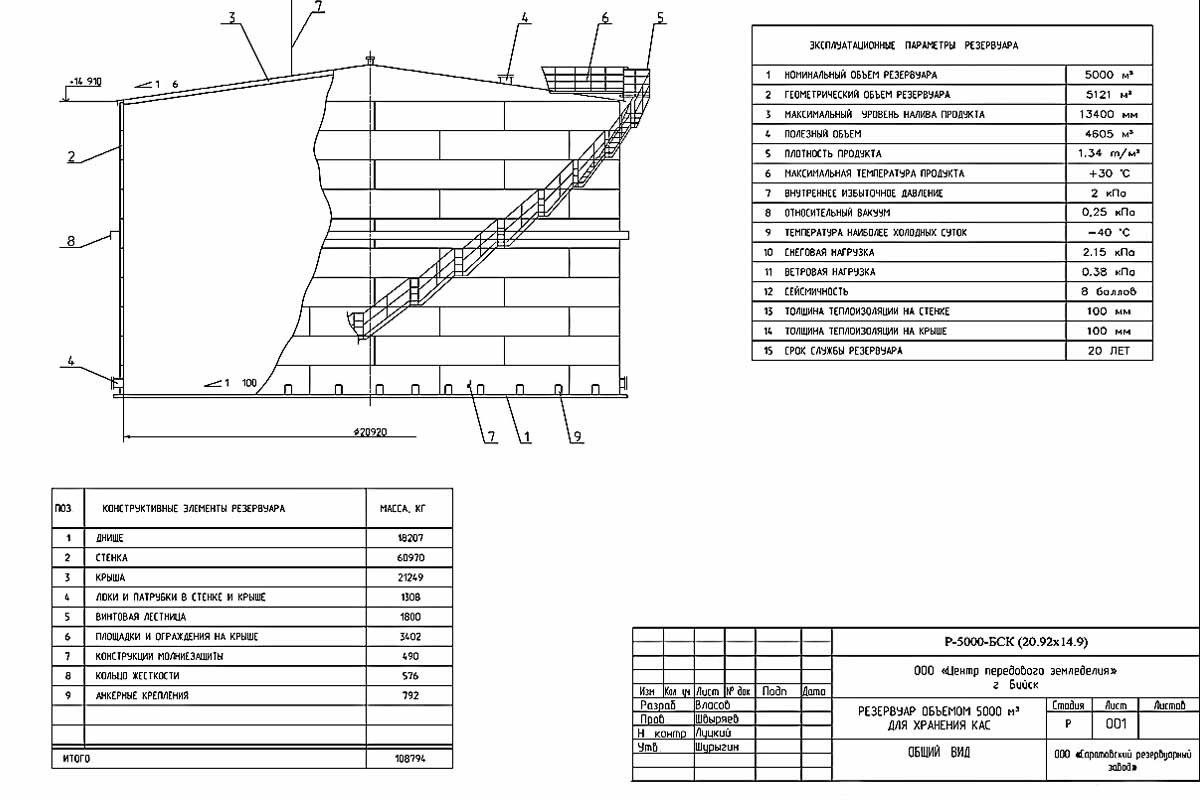

Main specifications:

- Stored product - urea ammonium nitrate (UAN);

- VST amount - 1 pcs with a capacity of 5000 m3;

- Material - 09G2S;

- Erection procedure - Roll method;

- Heat insulator assembly (mineral wool boards with a thickness of 100 mm, galvanized sheet with a thickness of 0,8 mm).

Specific features and complexities of the project

During the erection of a vertical tank with a capacity of 5000 m3 for urea-ammonia mixture storage in Biysk a roll method of erection was used.

One of the features of the end facility is the work performed in winter under adverse weather conditions (constant temperature fluctuation).

The main complixity of the project was the anti-corrosive coating application at sub-zero temperatures. Also, before painting it was necessary to prepare the surface for painting. For paint works, paint with "winter" composition was used, which made it possible to carry out work in the cooler seasons.

The Engineering department of the Saratov Reservoir Plant performed the following works:

- KM project and detailed design development for vertical tank in Biysk;

- production of rolled plates of vertical tank;

- tanks metal structures truck hauling;

- erection works (erection, painting, hydrotesting);

- thermal insulation of the tank shells is made of mineral wool boards with a thickness of 100 mm. A galvanized profiled sheet with a thickness of 0.8 mm was used as a coating.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design

Customer feedback

Chief executive officer R.А. Muzhbatullin

We give thanks to the employees of OOO "Saratov Reservuar Plant" for the project implementation of the erection of a vertical steel tank with a volume of 5000 m3 (VST-5000) for UAN storage in Biysk.

Within the framework of this project the specialists of Saratov Reservuar Plant performed the following works:

We would like to note that the anti-corrosive coating application and the thermal insulation assembly were being performed during a period with adverse weather conditions. Despite this, all the work on the implementation of this project was completed within the contractual terms. Cooperation with the specialists of Saratov Reservuar Plant was constructive and fruitful.

We were made sure of the high quality of the manufactured equipment, reliability and professionality of the Plant's specialists. We recommend Saratov Reservuar Factory as a reliable and responsible partner in the field of tank erection.