Tank farm extension in Ulyanovsk

Customer:

ООО "Lokar"

Location:

the Ulyanovsk Region

Company sector:

Mini oil refinery plant, hydrocarbon primary processing.

Date of works held:

August 2019 - October 2019

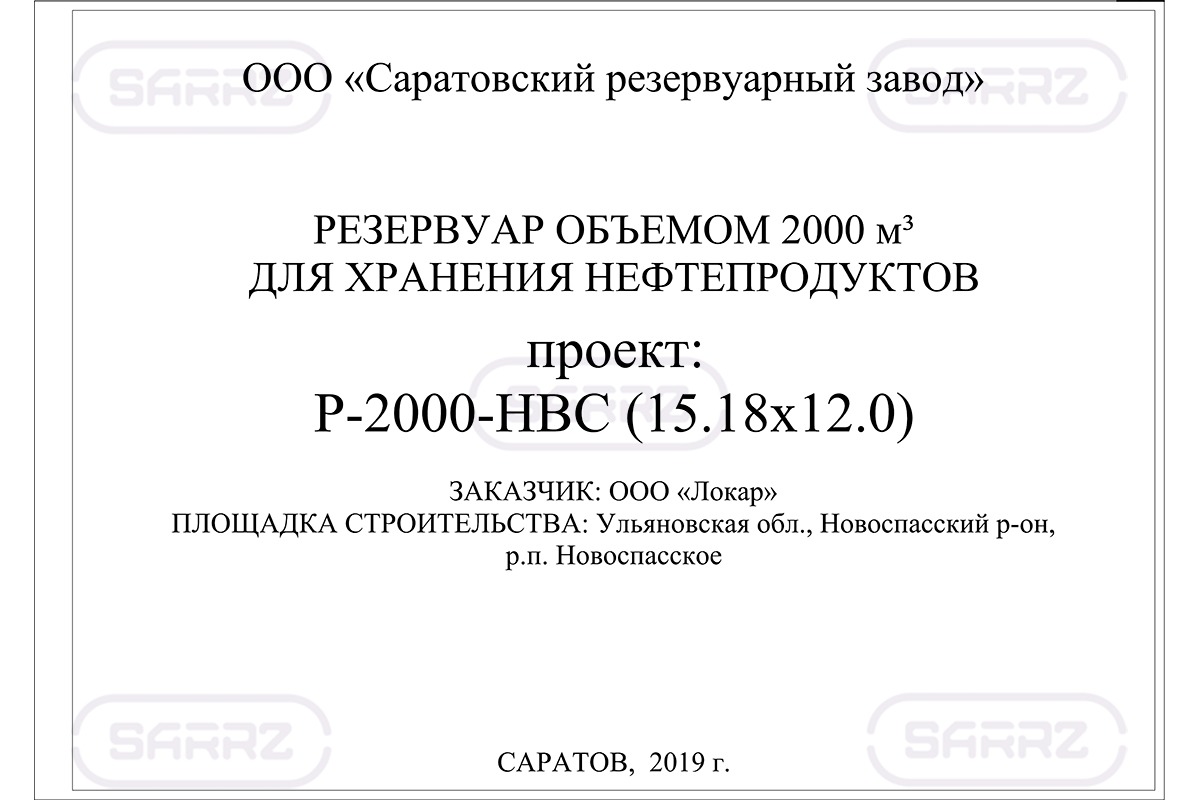

Project:

Storage farm extension by the process of vertical tanks construction (3 pcs)

In 2019, the Saratov Reservoir Plant completed a project work package in order to expand the Customer's tank farm, namely: the construction of three vertical tanks for process water storage (VST-700), and VST-1000 and VST-2000 (for diesel fuel storage).

With the view of fire safety precautions, the Customer needed service water. In this regard two vertical tanks with a total capacity of 1700 m3, with improved anti-corrosion protection of the inner surface were erected.

To increase the tank farm of processed petroleum products and diesel fuel ready for shipment, we designed, manufactured and installed a vertical tank with a capacity of 2000 m3.

Main specifications:

- Scope of supply: VST-700 m3, VST-1000 m3, VST-2000 m3;

- Stored product - processed water, diesel fuel;

- Material - Сt3sp5-sv;

- Dimensions: VST-700: diameter - 10430 mm, height - 8940 mm; VST-1000: diameter - 10430 mm, height - 11920 mm; VST-2000: diameter - 15180 mm, height - 11920 mm.

Specific features and complexities of the project

The newly erected vertical tanks for diesel fuel had to correspond to the common process chain of the existing petroleum refinery.

A tank for emergency water was introduced into the firefighting system of the facility.

Construction and assembly work was carried out on the territory of the existing mini oil refinery plant. In this regard, the close proximity to the operating tanks required increased fire safety measures of an object when performing welding.

It was also difficult to unroll the rolled shell of the tanks due to the close proximity of the tank to the dyke.

Specialists of the Saratov Reservoir Plant carried out a set of works on the construction of diesel fuel and fire water tanks. The scope of work was determined by thetechnical requirements for production and included:

- KM project development for each ordered tank;

- vertical tanks steel work manufacture from carbon constructional steel grade St3sp5 as per GOST 14637-89;

- delivery of the rolled plates of steel structures and optional tank equipment to the erection area by road;

- three vertical tanks erection;

- hydrotesting of the tanks.

For the period of delivery, the surfaces of steel structures were covered with preservation base coat. It was not required to apply finishing painting of the tanks at the facility. The operation of the tanks is carried out without thermal insulation.

Manholes, skylights, inlet - distribution nozzles, installation nozzles, stripping nozzles, platforms and ladders for the foam generator GPSS-600 (in the VST for diesel fuel) are provided in the tank shell and roof.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design