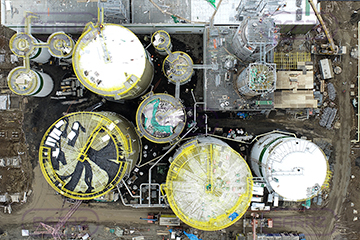

Tank farm construction for pulp and paper mill

Customer: Pulp and paper mill

Location: Ust-Ilimsk, the Irkutsk Region

Company sector:

Production of pulp and paper products.

Date of works held:

June 2020 - Februery 2022

Project:

Construction of a new pulp and cardboard mill in Ust-Ilimsk

For the worldwide leader of the pulp industry, the Saratov Reservoir Plant has completed a project for the complex supply of the Customer's facility with vertical tanks in the amount of 11 units with a capacity from 100 m3 to 7040 m3.

The expansion of the tank farm solved the Customer's issues to increase the output by 600 thousand tons per year. The erected tanks are part of a MEE aimed at increase the chemical materials concentration.

Our specialists have developed a complete set of design and detailed documentation for the production of tanks, their erection, thermal insulation, corrosion protection and hydraulic testing.

In accordance with the design consideration, the tanks were erected by the plate-by-plate method.

Main specifications:

- Amount of tanks - 11 pcs.;

- Processing medium - alkali;

- Tanks capacity: VST-100 m3, VST-150, a tank of pure condensate 306 m3, a tank of intermediate condensate 409 m3, a tank for sulphate soap 502 m3, an atmospheric tank of dense alkali 689 m3, a tank of soap decanter 1820 m3, a tank of accidental release 3540 m3, a tank of semi-evaporated alkali 4710 m3, a tank of solid alkali 7040 m3 (2 pcs.);

- Tank material - Aisi 304, 09G2S.

Specific features and complexities of the project

The project for the design and construction of a tank farm with a total volume of more than 25 thousand m3 was implemented in a short time, despite the remoteness of the facility and difficulties during construction.

The main difficulty of the project was the severe climate at the construction site: sharply sub-zero temperatures reduced the welding work pace in winter. The temperature conditions during the construction period also affected the continuous work of lifting machines.

Due to the work in confined spaces, the design consideration was a plate-by-plate method of vertical tanks erection.

The Project Office and the construction and erection department of the Saratov Reservoir Plant carried out a complex of design, production and construction and erection works, which included:

- development of KM, KMD (detailed design), TI (thermal insulation), PPR (project for implementation of construction operations) projects;

- manufacture of primary steel members and secondary steel of the vertical tanks;

- delivery of tank structures by road;

- foundation works, including the installation of a hydrophobic layer of concrete;

- erection of steel structures of vertical tanks by the plate-by-plate method;

- hydraulic testing of tanks and interconnecting piping;

- anti-corrosive protection of the tanks with GF-021 primer;

- installation of thermal insulation from mineral wool boards with a thickness of 100 mm and protecting cover from profiled and plain galvanized sheets.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design