Site Supervision of two tanks in the Republic of Guinea

Customer: ООО "COBAD S.A."

Location: the Republic of Guinea, Dugula region, Kamsar subprefecture, Boke prefecture

Company sector:

Mining and Quarrying in the Republic of Guinea.

Date of works held:

January 2019 - May 2019

Project:

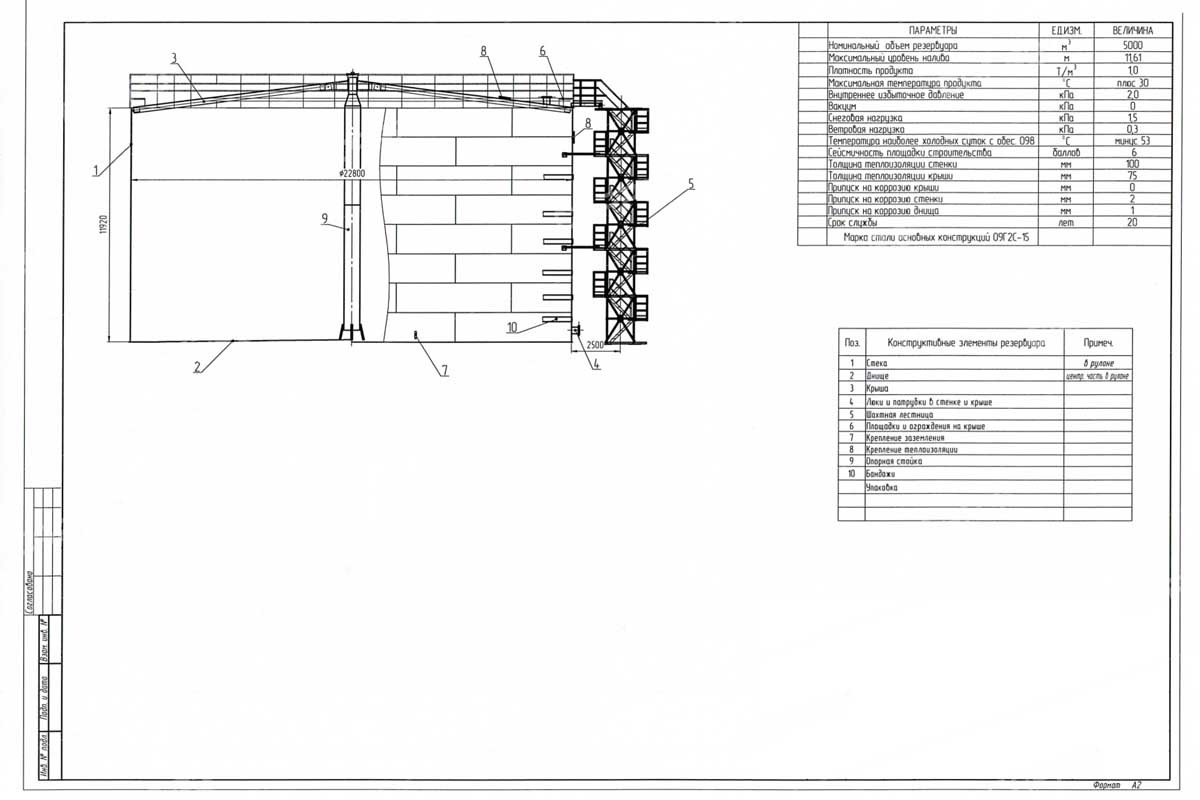

Site Supervision of two vertical tanks for fuel oil storage in the Republic of Guinea

The basic feature of the fulfilled project was the construction for a foreign customer outside the territory of the Russian Federation. The priority for the Customer was the choice of a reliable contractor and the professional competence of the company, which could confirm the compliance of its end projects with quality standards. Due to the high level of quality of the work performed, the SARRZ Plant was able to establish give-and-take relationship with the Customer and implement the project in accordance with the approved technical specifications for execution of works.

Main specifications:

- Stored product - fuel oil;

- VST amount - 2 pcs with a capacity of 250 m3 each;

- Material - 09G2S;

- Erection procedure - Roll method.

Specific features and complexities of the project

The main challenge of the end project was execution of works for a foreign customer outside the Russian Federation in a sub-equatorial climate with a pronounced sequence of dry and wet seasons.

The set of works included the design, manufacture of steel works, site supervision, providing briefing on the operation and maintenance of the tanks. The total time spent on carrying out the full scope of work was 4 months.

The basis of design documentation was developed according to API 650 standards and adapted to GOST 31385-2016.

The development of the design documentation included KM project (metal structures), TI project (heat insulation).

The manufacture of the vertical tanks steel structures was carried out by roll method from steel grade 09G2S. The order content also included the manufacture of an internal tubular heating register.

Erection procedure at the facility included the rolling-up of tank shell plates, welding of butt joints, laying of roof steel structures.

Within the contract the personnel were instructed on the operation and maintenance of the tanks.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design