Hot water tank manufacture and installation for the boiler house in Surgut

Customer: Grid distribution company

Location: Surgut, the Khanty-Mansijsk Autonomous District

Company sector:

Electricity distribution, as well as the design and installation of electrical networks.

Date of works held:

September 2019 - December 2019

Project:

Major repairs of the hot water tank at "Boiler house for neighbourhood unit № 38 and № 39 heat supply"

The Customer, being the main grid distribution company in Surgut, set high requirements to the contractor, as the quality of services provided for the citizens depends on the performance of work, since the heating supply boiler house is a socially significant facility.

In accordance with the contract awarded, the restoration of the performance characteristics of the hot water tank, including the reliability and efficiency of its operation, as well as maintaining the specified operating conditions during the time between overhauls, depended on the Saratov Reservoir Plant.

The hot water tank itself is designed for receiving, storing and issuing process water, namely washing liquid and mixture, at the metering unit.

Main specifications:

- Stored product - hot water at the temperature up to +75ºС;

- Number of tanks - 1 pcs., with a volume of 100 m3;

- Material - 12Х18Н10Т according to GOST 7350 and GOST 5632;

- Structural elements: plate-by-plate shell and bottom, flat-deck frame roof (frame under the roof sheeting);

- Optional: heat insulation with a thickness of 10 mm;

- Overall dimensions: diameter 4121 mm, height 7000 mm.

Specific features and complexities of the project

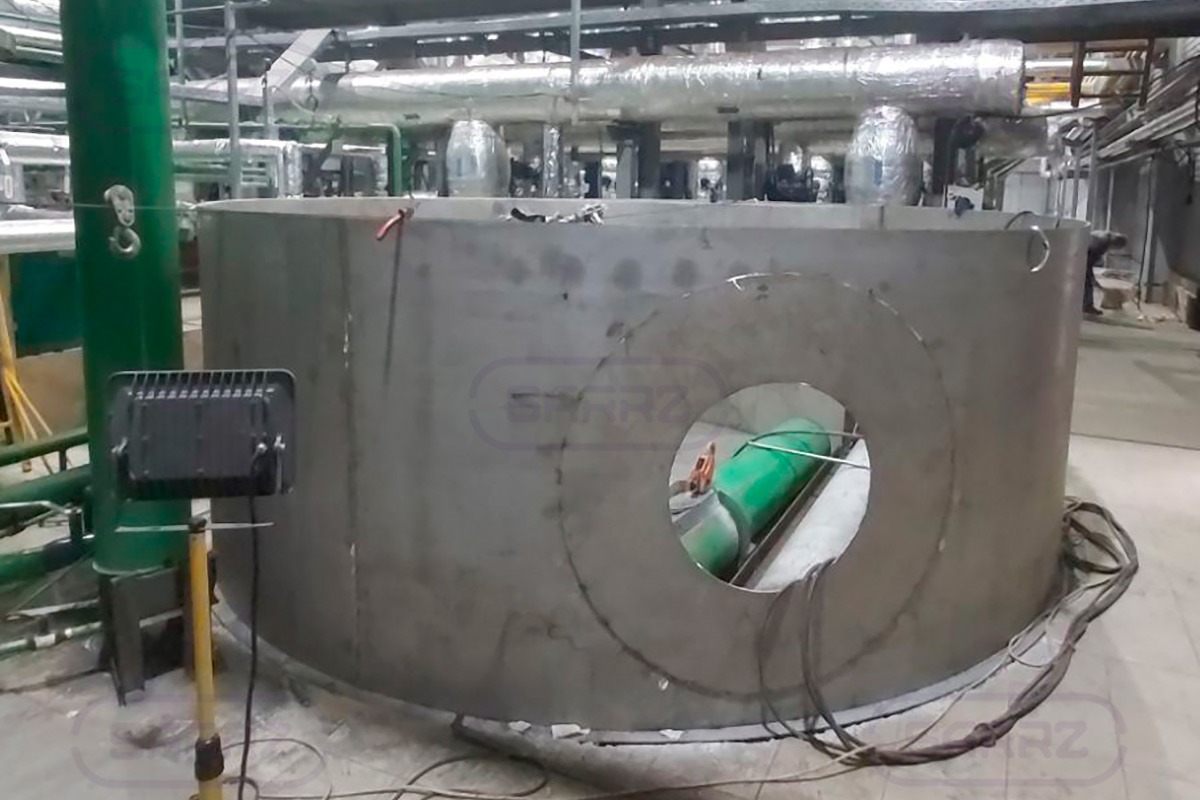

The main feature of the completed construction project was the lack of space at the facility: the work was carried out inside the operating boiler room. In this regard, the steel structures of the hot water tank were made by the plate-by-plate method due to the impossibility of the tank delivery and installation of the pre-fab ready-to-operate version of the equipment.

Due to the high importance of the facility, it was necessary to perform all the work in a short time: design, manufacture, delivery, installation and hydraulic testing took 3 months.

As a heat-insulation material Penofol 2000 (based on the foamed polyethylene and foiled on one side) was used.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design

Customer feedback

CEO Pack M.Ch.

OOO "Surgutskie municipal electrical services" expresses its gratitude to OOO "Saratov Reservoir Plant" for the responsible fulfillment of the obligations for the design, manufacture, supply and installation of hot water tank 100 m3 made of 12X18H10T steel grade with the assembly of heat insulation for the construction of the facility "Boiler house for neighbourhood unit № 38 and № 39 heat supply".

The complexity of this project was the work in confined spaces.

We would like to note the high level of technical expertise of OOO "SARRZ" and its readiness to respond quickly and efficiently to the customer expectations.

We recommend ООО "SARRZ" as a reliable partner, ensuring the achievement of the proper result within the terms established by the contract.