Bitumen storage tank farm upgrade

Customer: OOO «TN-SHINGLAS Saratov»

Location: Dubki, the Saratov Region

Company sector:

International manufacturer of roofing and heat insulation materials.

Date of works held:

June 2021 - August 2022

Project:

TRepair and construction of a bitumen storage tank farm as part of the bitumen storage facility upgrade in Saratov

Under the project of the bitumen storage tank farm reconstruction, the Saratov Reservoir Plant performed a work package on the repair and construction of tanks for a large manufacturer of constructional materials.

The Project Office, the manufacturing department and the construction and construction and erection department were involved in the work.

According to the contract with the Customer , the works under the Project included:

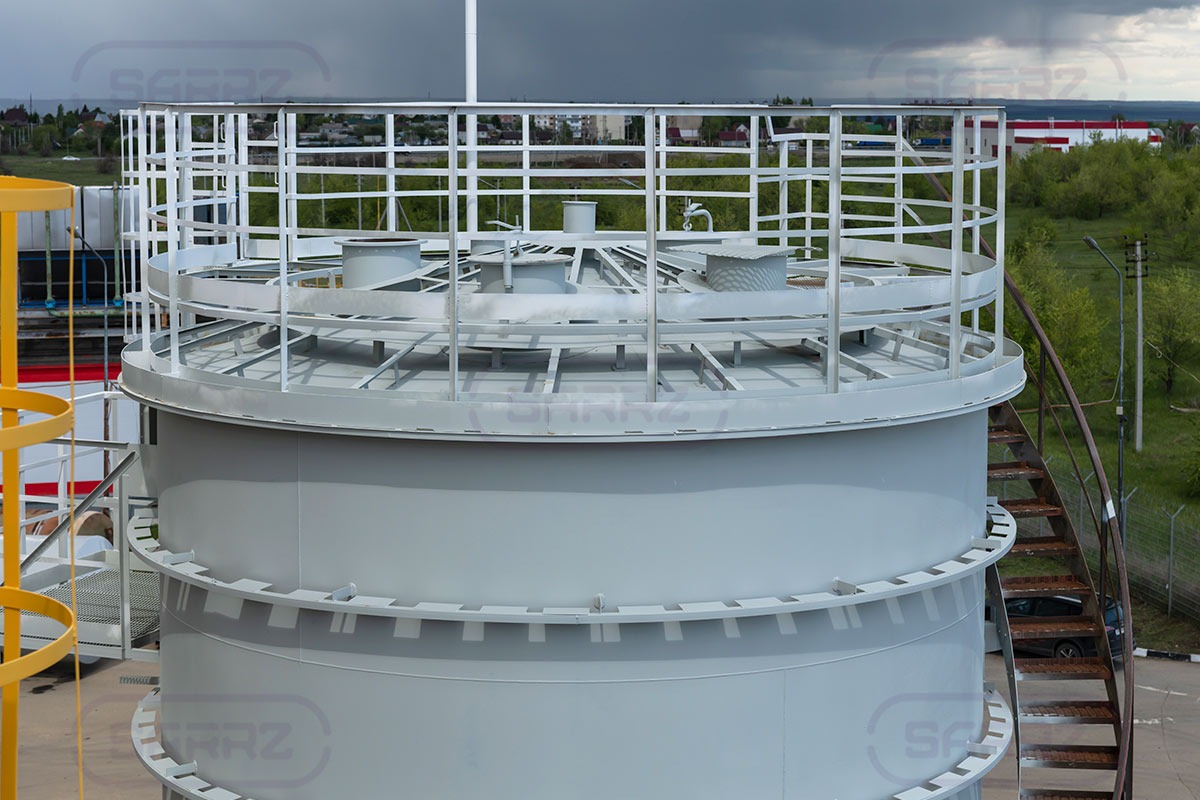

- tanks repair: vertical tanks VST-548 m3 and VST-270 m3;

- tanks erection: two vertical tanks VST-270 m3.

To implement the project, the Project Office designed KM, TN (heating elements) and TI (thermal insulation) projects for the repair steel structures and steel structures of new tanks.

Main specifications:

- Stored product - bitumen;

- Tank material - steel St3sp5;

- List of works - KM, TI and TN projects design for tanks, their repair and erection;

- The list of the repair work - renewal of the roof, reconstruction of the heat element, installation of heat insulation, anti-corrosion protection;

- The list of tanks erectionwork - design, manufacture and erection of two vertical tanks VST with anti-corrosive coating application and heat insulation.

Specific features and complexities of the project

Project activities included both the design and erection of new tanks and the complete reconstruction of the existing tanks at the facility.

The work was performed with frequent unplanned downtime due to weather conditions at the construction site, namely abnormally abundant snowfall and strong winds.

The design consideration of the tanks roof was the seam lock of heat insulation mats, which is a rare way of mounting the coating material.

All works under the general contract were performed in accordance with the completed contract, with the exception of the site organization and hydraulic testing of tanks.

Complex works on the bitumen storage tank farm upgrade included:

- KM projects design for repair steel structures of vertical tanks with a capacity of 270 m3 and 548 m3;

- KM projects design for steel structures of new two tanks with a capacity of 270 m3 each;

- TI (thermal insulation) and TN (heat elements) projects design;

- manufacture of repair steel structures and steel structures of new tanks;

- repair and erection of new tanks, namely renewal of roofs, reconstruction of heat elements, installation of thermal insulation, anti-corrosion protection application on external surfaces;

- hydraulic testing of four tanks.

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design