Bitumen depot terminal construction in Tomsk

Customer: ООО "DSM"

Location: Tomsk, the Tomsk Region

Company sector:

Road materials, asphalt products fabrication.

Date of works held:

August 2018 - April 2019

Project:

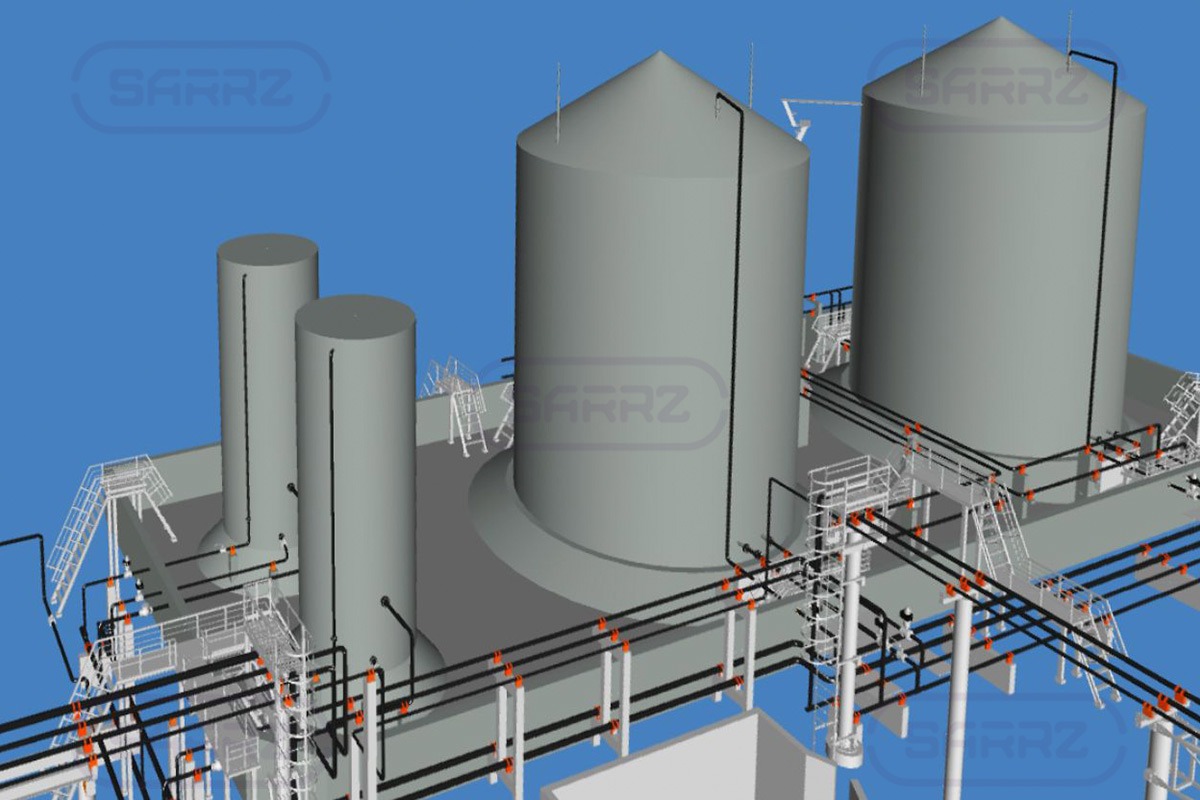

Bitumen depot terminal construction in Tomsk

The Customer's priority when choosing a performing company was the possibility of implementing a turnkey project by one contractor and the delivery of tanks by the certain period of time. Due to the high level of quality of the work performed, the SARRZ Plant implemented the project in accordance with the approved work specification and executed the work within the time specified.

Main specifications:

- Stored product - bitumen;

- VST amount - 2 pcs with a capacity of 1000 m3;

- Material - 09G2S;

- Erection procedure - Roll method;

- Colour match for the corporate identity (colour RAL7004 and RAL6005).

Specific features and complexities of the project

The major challenge of the project execution was adverse climatic conditions (the winter period under negative temperature conditions), as well as the implementation under the conditions of an operating enterprise.

The equipment package design was performed taking into account the limited operating space at the facility. The object was visualized using a 3D model.

Thermal oil heaters were installed into the tanks, which have a custom design to maintain effective bitumen convection.

Commissioning of the steam generation plant and erection supervision work of the piping manifold of the steam generation plant were performed.

The Engineering department of the Saratov Reservoir Plant performed the following works:

- facility design, undergoing technical expertise on design / project documentation, preparation of designs;

- manufacture of VST steel structures and accessory equipment, steam generator plant;

- delivery of equipment by road;

- construction and assembly work and erection supervision work;

- conducting hydraulic tests and NDT inspection of structures;

- anti-corrosive coating application on the external surfaces of the tanks (heat-resisting enamel КО-801 in 2 layers);

- heat insulator assembly (with a thickness of 100 mm) and covering coat (profiled sheet RAL704 and RAL6005 with a thickness of 0.7 mm).

Do you want to get a calculation of designed cost?

In order to find out the cost of the project, SARRZ makes engineering design based on the running conditions and Customer requirements. Information about the project and requirements:

- may be discussed at +7(8452)250-288

- may be sent by e-mail zakaz@sarrz.com in a form of a completed Data sheet or technical requirements (capacity, performance requirements, operating medium and its characteristics, operating conditions, general description of the production line)

The Saratov Reservoir Plant performs multiple services for the oil and gas facilities construction. We offer:

- engineering surveys at oil and gas facilities, including highly dangerous and technically challenging objects

- the design, project development and authority engineering approval of the oil and gas and chemical facilities construction

- vertical tanks, vessels, apparatus and other metal structures fabrication

- manufactured products delivery and installation in accordance with the tie-in design

Customer feedback

Director manager of ООО "DSM" Karpenko S.P.

By this letter, OOO " DSM " expresses its gratitude to the Engineering department of OOO "SARRZ" for the Preparation of designs for the object: "Equipment for the storage and transshipment of bitumen - active storage with a volume of 2000 m3 located at the address: 1-Y Vilyuyskiy Proezd, 4G, Tomsk,".

Under the project, engineering solutions for the bitumen storage farm with a volume of 2000 m3 were developed, the documentation was completed on time at the proper level of engineering, thus having received a positive findings.

In the process of work, the specialists of SARRZ proved themselves as a well-coordinated, technically competent team, ready to listen to the Customer and promptly respond to all his wishes.

We wish you new challenging project.